Adjusting the tension of the differential bearings and monitoring the lateral clearance in the engagement of the main gear

The lateral clearance in the engagement of the main gear, which has increased due to wear of the teeth, is not reduced by adjustment, because this leads to a disruption of engagement and, as a consequence, to increased wear of the teeth, increased noise or breakage of the teeth

Increased clearances in the bearings are eliminated without disturbing the relative position of the gears.

To adjust the bearings, it is necessary to:

Drain the oil through the drain hole;

Remove the crankcase cover;

Unscrew nuts securing the axle shaft to the hub, remove the spring washers and four expansion bushings from the studs.

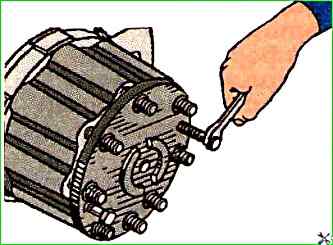

Screw two M10x1.5 bolts into the flange holes (Fig. 1), move it from its place, then manually remove the axle shaft, gasket and seal housing together with the seal.

Remove the other axle shaft in the same way;

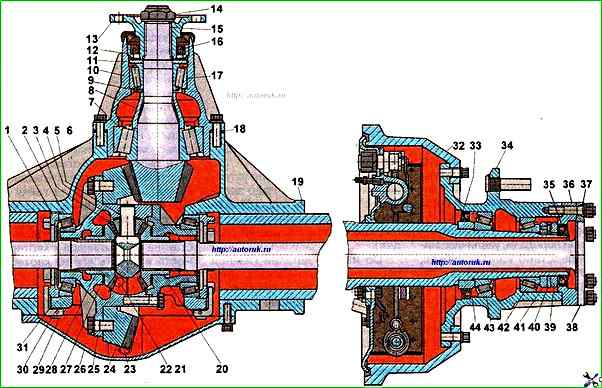

Remove cotter pins 29 (see Fig. 2) from stoppers 30;

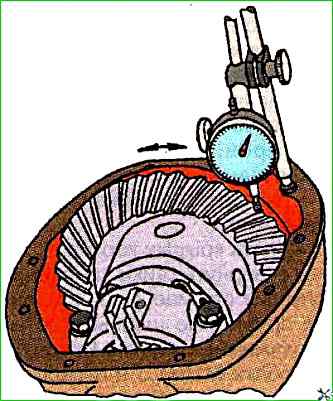

The lateral clearance in the engagement is measured with an indicator installed on the wide part of the tooth (Fig. 3).

The clearance should be 0.2-0.28 mm.

The final clearance check should be carried out after adjustments bearing preload and contact patch in engagement;

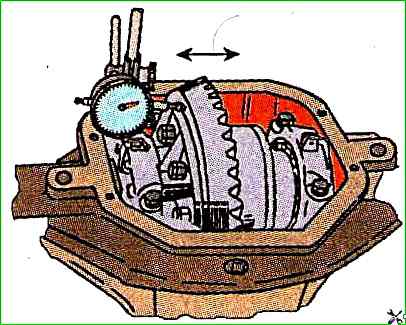

To ensure the required preload in the differential bearings, first tighten the adjusting nuts evenly until the axial clearance (without tension) in the bearings is eliminated, while turning the differential to correctly install the rollers in the bearings.

If it is difficult to rotate the adjusting nuts, then it is necessary to unlock and loosen the tightening of the bearing cap bolts.

The axial clearance is measured with an indicator (Fig. 4);

To obtain the correct preload, the nuts on both sides are tightened two notches from the zero clearance position.

After the final check of the lateral clearance in three evenly spaced teeth, the adjusting nuts are locked.