Adjusting the contact patch in the main transmission gears of the ZIL-5301

After adjusting the main transmission bearings, it is necessary to check the engagement of the teeth of the driving and driven bevel gears (on the paint on the contact patch) and, if necessary, adjust the engagement and set the required gap between the teeth.

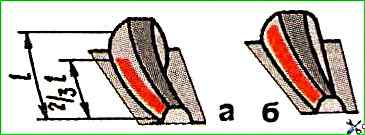

The position of the contact patch on the teeth of new gears with adjusted gear engagement should correspond to the contact patch shown in Fig. 1(a), and under load - in Fig. 1,(б).

The gap between the teeth must be maintained within 0.2÷0.28 mm for new gears and 0.5 mm (no more) for used ones.

After adjusting the driving and driven bevel gears, it is necessary to finally tighten the differential bearing cap mounting bolts.

The tightening torque should be 160÷200 Nm.

The gap between teeth are measured with an indicator at the wide part of the tooth for at least three teeth of the driven gear, evenly spaced around the circumference.

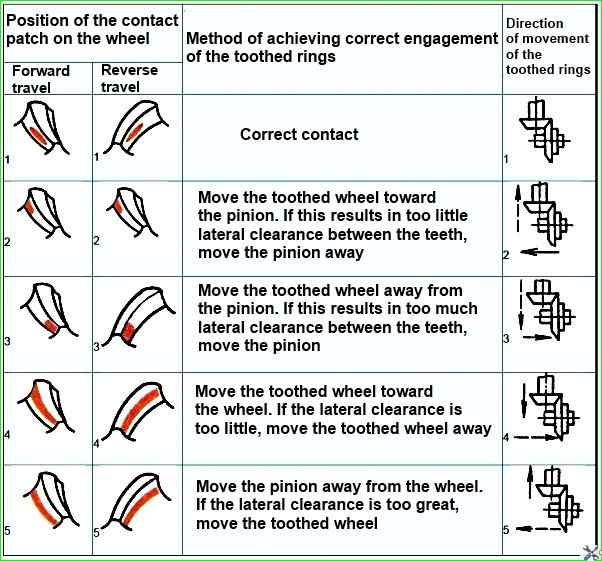

For normal setting of the engagement of the gear teeth, a thin layer of oil paint should be applied to the working surfaces of several teeth of the driven bevel gear along the contact patch.

Then turn the shaft of the leading bevel gear in one direction and the other, braking the driven gear by hand.

The nature of the engagement of the gears is determined by the resulting contact patches.

The correct setting of the engagement of the gears is shown in Figure 1.

If the position of the patch is incorrect, normal engagement should be achieved by moving the leading and driven gears in the axial direction, proceeding in accordance with the table.

The driving bevel gear is moved by changing the thickness of the set of adjusting shims installed between the flanges of the bearing cup of the driving gear and the gearbox housing, the driven one - by rotating the left and right adjusting nuts of the differential bearings by the same amount so as not to disturb the adjusted preload of the bearings.