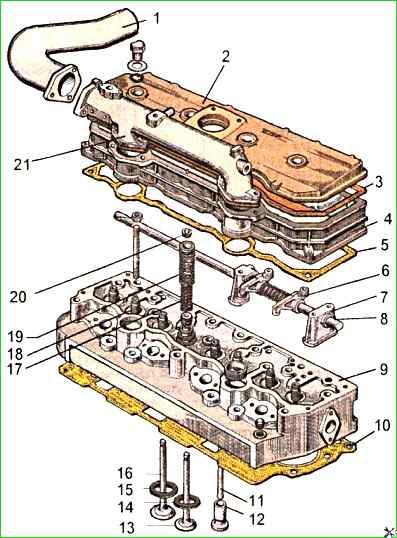

The cylinder head is a cast iron casting, in the internal cavities of which there are inlet and outlet channels closed by valves

To ensure heat dissipation, the cylinder head has internal cavities in which coolant circulates

The cylinder head 9 has inserted valve seats 14 and 15 made of heat-resistant and wear-resistant alloy.

The cylinder head is equipped with pillars 7, rocker shaft 8 with rocker arms 6, head cover 4, intake manifold and cap 2 of the cover, covering the valve mechanism.

Four injectors are installed in the head on the fuel pump side, and the exhaust manifold is attached to the head on the generator side.

A gasket is installed to seal the connector between the head and the cylinder block 10 made of asbestos-steel cloth.

The openings for the cylinder liners and the oil channel are edged with sheet steel.

When assembling a diesel engine at the factory, the cylinder openings of the gasket are additionally edged with fluoroplastic split rings.

The cylinder head must be cleaned of scale, carbon deposits and washed.

Cracks and leaks in the seating of technological plugs are not allowed.

During hydraulic testing of the liquid jacket of the cylinder head under a pressure of 0.40±02 MPa for 3 minutes, leaks and the appearance of drops are not allowed.

After replacing leaky plugs, the cylinder head should be retested for leaks.

The non-flatness of the surface of the cylinder head mating to the block should not exceed 0.1 mm along the length of the head (0.05 mm for a new head).

The non-flatness of the surface of the cylinder head mating to the exhaust manifold should not exceed 0.2 mm along the entire length (0.1 mm for a new heads).

The height of the cylinder head must be at least 100.7 mm (103-0.22 mm for a new head).

The threaded holes for the studs in the cylinder head must not be damaged.

The working chamfers of the valve seats and plates must be machined at an angle of 45 + 0.5.

The runout of the surface of the working chamfer of the seat relative to the surface of the guide sleeve after processing must not exceed 0.05 mm.

The runout of the surface of the working chamfer of the valve plate relative to the surface of the stem is allowed to be no more than 0.03 mm.

The width of the working chamfer of the seat after processing must be 2.0-2.2 mm.

The height of the cylindrical belt of the valve plate must be at least 1.5 mm.

Valve seats cooled to -120°C must be pressed into the cylinder head heated to 70°C.

The protrusion of the guide sleeve above the plane of the cylinder head, i.e. the size from the upper end of the guide sleeve to the surface of the cylinder recess for the valve springs, must be 33-1.0 mm.

The valves must be ground and tightly fit against the seats.

The quality of the lapping should be checked by the presence of an annular matte strip on the conical surfaces of the valve and seat.

The width of the strip must be 15-2.0 mm; breaks in the strip are not allowed.

The width of the lapped chamfer of the valve seat must be the same along the entire length; the difference in the width of the ground chamfer of the seat is allowed to be no more than 0.5 mm.

The strip on the valve should be located no further than 1.0 mm from the edge of the cylindrical belt of the valve plate.

The tightness of the valve plate to the seat should be checked with a pneumatic device KI-16311 - at an air pressure of 0.03-0.05 MPa; air leakage (the appearance of bubbles) is not allowed.

It is allowed to check the tightness of the valves to the seats by pouring kerosene into the inlet and outlet channels; leakage or appearance of kerosene drops from under the valve plates for 2 minutes is not allowed.

After grinding the valves to the seats, the cylinder head and valves must be washed until the grinding paste is completely removed from the parts.

The valve stems in the guide bushings must move freely, without noticeable transverse rocking.

Before assembly, the valve stems must be lubricated with M-10G2 engine oil.

The recession of the lower planes of the intake and exhaust valve plates relative to the lower plane of the cylinder head must be within 1.05-1.25 mm.

When installing the plugs in the cylinder head, it is allowed to seal them with zinc or titanium lilacs.

The ends of the plugs after pressing should not protrude above the plane of the cylinder head.

The non-straightness of the valve stem is allowed over the entire length of no more than 0.022 mm (for a new valve - 0.015).

Cracks and hairlines are not allowed on the valve surfaces. 100% of the valves are subject to inspection. The inspection should be carried out using the fluorescent method.

Valve springs must be subjected to 100% inspection on a magnetic flaw detector; cracks in the springs are not allowed.

The gap between the end and working threads of the valve springs must be no more than 0.3 mm when measured at a distance of 5-10 mm from the end of the coil.

The non-perpendicularity of the bearing surfaces of the valve springs to their axis in a free state is allowed to be no more than 1° along the length of the springs.

When inspecting the bearing surfaces of the springs, they must be flat on an arc of at least ¾ of the circumference of the end coil.

After screwing the studs into the cylinder head, dents up to 0.1 mm deep are allowed in areas that do not have threads.

The crackers must protrude above the plane of the valve spring plate no more than 1.4 mm; recess no more than 1.8 mm.

Rocker arm mechanism

The rocker arm adjusting screws must be screwed into the rocker arms along the entire length of the thread, and the locknuts must be screwed onto the screws tightly, but without jamming.

The surface hardness of the rocker arm striker must be 49-57 HRC. The roughness of the machined surface of the striker should be Ra≤0.3 μm.

The rocker arm posts should fit tightly against the supporting surface of the cylinder head.

The rocker arm shaft plugs should be tightly screwed in and ensure the tightness of the connections.

The oil channels of the valve rocker arms and the rocker arm shaft should be thoroughly cleaned, washed and blown out with compressed air.

The rocker arms should rotate freely on the rocker arm shaft without jamming.

The radial runout of the rod relative to its spherical surface is allowed up to 0.5 mm.

The non-flatness of the surface of the cover adjacent to the cylinder head and the surface of the cover adjacent to the cover cap is allowed to be no more than 0.25 mm over the entire length.

Intake and exhaust manifolds

The surfaces of the flanges adjacent to the cylinder head must be in the same plane; under a load of at least 300 N, the deviation from flatness is allowed to be no more than 0.15 mm (for a new flange - 0.1 mm).

The internal surfaces of the intake manifold must be clean, without carbon deposits and soot.

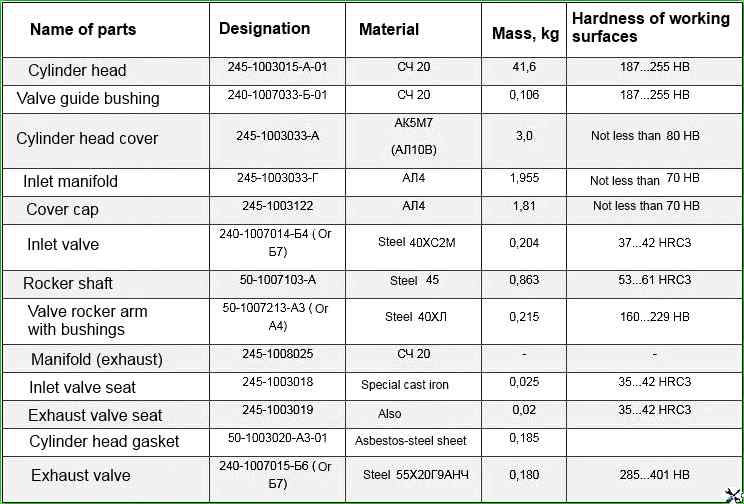

Main parameters of the head and valve timing components

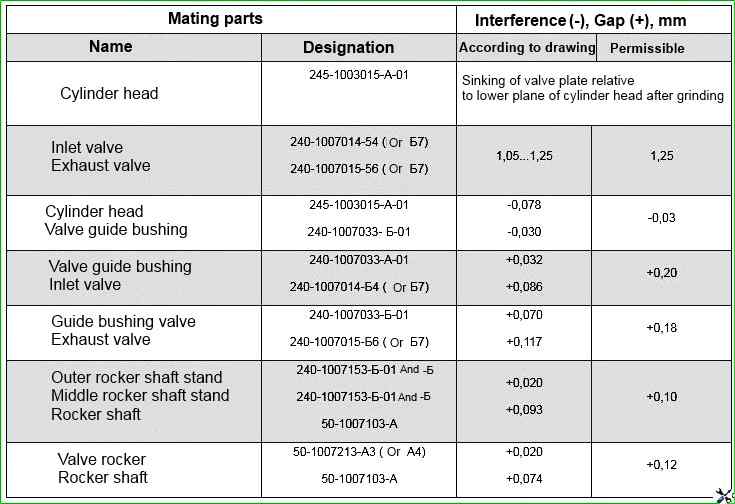

Mounting connections of the cylinder head and its components