Replacing the fine fuel filter

The service life of the fine fuel filter depends on the purity of the fuel used

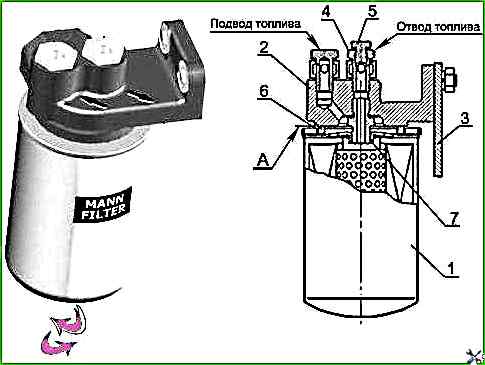

Replace the filter every 25 thousand km or according to the results of diagnostics of the “COMMON RAIL” system in accordance with Figure 1, for which:

- - unscrew filter 1 from fitting 7 in housing 2 and install a new Mann & Hummel WDK962, supplied assembled with gasket 6, which is pre-lubricated with engine oil;

- - after gasket 6 touches installation pad “A” on body 2, tighten the filter another ¾ turn. At the same time, tighten the filter only with your hands;

- - open the fuel tank tap and fill the system with fuel.

Filling the fuel system

Cranking the diesel engine with the starter when the power supply system is not filled with fuel is prohibited. The high pressure fuel pump will fail.

To fill the fuel system, it is necessary to remove air from it (bleed the system) for which:

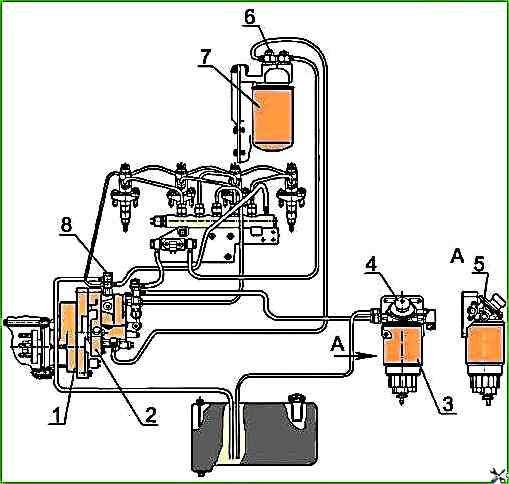

Unscrew plug 5 (Figure 2) located on the fuel pre-filter housing by 2-3 turns.

Pump the system using booster pump 4 located on the body of the fuel pre-filter 3, screw in plug 5 (tightening torque 15-20 Nm) until fuel appears without air bubbles.

Unscrew plug 6 located on the bolt securing the outlet fitting of the fine fuel filter by 2-3 turns.

Continue pumping the system using the booster pump, tighten plug 6 (tightening torque 15-20 Nm) after fuel appears without air bubbles.

Unscrew the bolt of the rotary angle 8 securing the drainage pipes on the body of the high-pressure pump 1 by 2-3 turns and continue pumping using the booster pump until fuel appears without air bubbles.

Tighten bolt 8 (tightening torque 30-40 Nm).

Air purifier maintenance

Service the air purifier with paper filter elements made of special highly porous cardboard every 80 thousand km or, if necessary, according to the readings of the clogging indicator.

Maintenance of the air purifier consists of blowing out the main filter element, which traps dust entering the air purifier.

Contamination of the control filter element indicates damage to the main filter element (break of the paper curtain, peeling of the bottoms).

In this case, it is necessary to blow out the control filter element, and replace the main one.

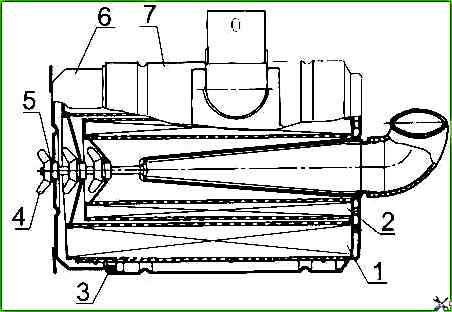

Service the air cleaner in accordance with Figure 21 in the following sequence:

- - remove tray 6;

- - remove the main filter element 1.

It is not recommended to remove control filter element 2 from the housing.

Blow off the main filter element with compressed air, first from the inside and then from the outside until the dust is completely removed.

To avoid breaking through the paper curtain, the air pressure should be no more than 0.2-0.3 MPa.

The air stream should be directed at an angle to the surface of the filter element.

During maintenance, it is necessary to protect the filter element from mechanical damage and oiling.

Do not blow the filter element with exhaust gases or wash it in diesel fuel.

Clean the supply pipe, the internal surfaces of the housing and the air cleaner tray from dust and dirt.

Before assembling the air purifier, check the condition of the O-rings.

When assembling, make sure that the filter elements in the housing and tighten the wing nut securely by hand.