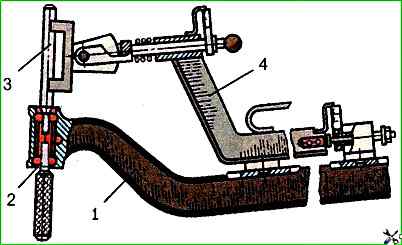

When repairing, the front axle beam must be checked for bending and twisting on a device (Fig. 1), which is installed on the spring platform

The device prism is guided by a lock installed in the holes for the kingpin and secured with an expansion collet

Bending and twisting, as well as the angle of inclination of the hole for the kingpin, are determined using scales. to check the opposite side of the beam, the device is reinstalled.

The beam is straightened in a cold state under a hydraulic press.

After straightening, the angle of inclination of the axis of the hole for the kingpin to the vertical axis should be within 7°45' - 8° 15'.

The non-perpendicularity of the hole for the kingpin relative to the spring pads should not exceed 0.5 mm.

Non-perpendicularity The allowable deviation of the beam boss ends relative to the kingpin holes is no more than 0.2 mm.

If the beam is bent beyond repair, it should be replaced.

If the front axle parts are worn beyond the permissible dimensions, the worn parts should be replaced.

Cracks on the surface of the front axle parts are not allowed.

If the steering knuckle eye under the front axle beam is worn beyond the permissible size of 68.06 mm, it is recommended to treat the worn surfaces and install compensating washers during assembly.

If the eye is worn more than 68.5 mm, the steering knuckle should be replaced.

Damage to the steering knuckle threads by more than two threads is not allowed.

It is recommended to press out worn steering knuckle bushings and replace them with new ones. The pressing force for the bushings should be at least 10,000 H.

Steering knuckles with worn journals for bearings should be replaced.

The main dimensions of the front axle parts are given in the table.

Main dimensions of the front axle parts

Parameters - nominal size, mm - permissible without repair, mm

Front axle beam. Steel 45, GOST 1050-74, hardness 285-341HB:

Length of the beam at the centers of the holes for the kingpin - 1633

Diameter of the hole for the kingpin - 30.00-30.033 - 30.06

Diameter of the hole for the kingpin locking wedge - 13.00-13.11 - 13.24

Height of the bosses for the kingpin - 49.00-50.00 - 48.80

Steering knuckle. Steel 40X, GOST 4543-71, hardness 241-285HB:

Neck diameter for outer bearing - 35.975-35.991 - 35.955

Neck diameter for inner bearing - 44.975-44.991 - 44.955

Diameter of hole for kingpin bushings - 33.00-33.039 - 33.07

Neck diameter for hub seal ring - 50.034-50.050

Width of eye for front axle beam - 67.90-68.36 - 68.50

Trunnion thread - M30x1.5-4h

Steering knuckle arms Steel 40x, GOST 4543-71, hardness 269.302 HB:

Diameter of the large cone hole for the ball pin - 20.0

Diameter of the holes for the lever mounting bolts - 16.095-16.205 - 16.4

Misalignment of the end face of the large diameter of the cone hole and the cone gauge - 0.3

Taperage of the hole for the ball pin - 1/8

Steering knuckle kingpin steel 18khgg, GOST 4543-71, depth of the nitrocarburized layer - 1.0-1.4 mm, surface layer hardness - 59.63 HRC:

Kingpin diameter - 29.987-30.00 - 29.97

Steering knuckle bushing. Tape thickness 1.8 mm BrOCS 4-4-2.5, GOST 15885-77:

Outer diameter of the bushing (in ring gauge) - 33.112-33.174

Front wheel hub casting KCh 35-10-f or VCh 40:

Diameter of the hole for the outer bearing ring - 35.975-35.991 - 35.955

Diameter of the hole for the inner bearing ring - 44.975-44.991 - 44.955