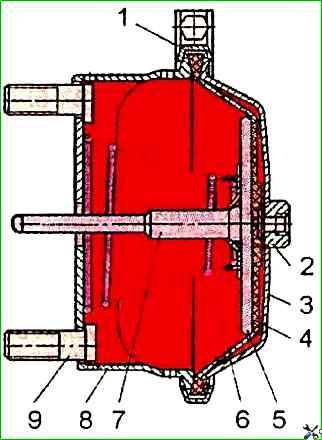

Pneumatic brake chamber ZIL-5301

On ZIL-5301 vehicles with drive separation by axles and on ZIL buses, flangeless brake chambers are used, designed to act on the main brake cylinders and installed together with them on brackets

The brake chamber structure is shown in the figure.

Before disassembling, the brake chamber must be removed from the bracket and disconnected from the main brake cylinder.

To disassemble the chamber, it must be clamped in a device with a screw;

Unscrew the clamp bolt 1;

Remove the clamps and, releasing the screw of the device, since the spring 6 creates a force of more than 50 dan, separate the housing 8 and the cover 3.

Remove the rod 7, membrane 4 and spring 6.

Assemble the chamber in the reverse order.

In this case, special attention should be paid to the correct relative position of the housing, cover and membrane.

After repair, the chamber must be checked for operability and tightness.

To check the operability of the chamber, it is necessary to supply air three times under a pressure of 0.75 MPa into the chamber cavity.

In this case, the rod should quickly extend without jamming and return to its original position.

To check To ensure tightness, moisten the joints of the cover and the body with soap emulsion and apply air under a pressure of 0.75 MPa.

To eliminate air leakage, tighten the clamp mounting bolts.

If the leak continues, replace the membrane or straighten the clamps.