The high-pressure fuel accumulator (Rail) is a volumetric fuel storage tank under high pressure

At the same time, the accumulator smooths out pressure fluctuations that occur due to the pulsating fuel supply from the high-pressure fuel pump,

as well as due to the operation of the injectors during injection due to the asynchronous pressure pulses of the fuel doses coming from the high-pressure fuel pump and consumed through the injectors, as well as due to the multiple excess of the mass of fuel in the accumulator and acting as a damper for the pressure pulses of small doses of fuel, coming and being consumed.

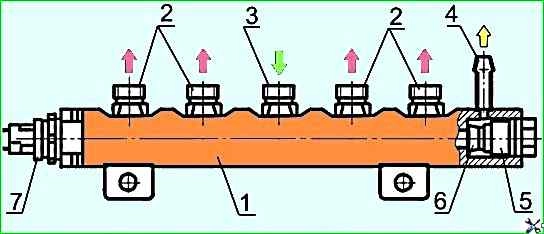

The accumulator (fuel rail) 1 in general has the shape of a pipe, at the ends of which the fuel pressure sensor 7 and the pressure limiting valve 5 are installed.

Along the generatrix of the perimeter of the pipe there are fittings for connecting high-pressure fuel lines 2; 3 and return drain nipple 4.

Fuel from the high-pressure fuel pump is directed through the high-pressure line to the inlet nipples 3 of the accumulator.

The fuel accumulator communicates with the injectors via high-pressure fuel lines connected to the outlet nipples of the accumulator.

The accumulator volume is constantly filled with fuel under pressure.

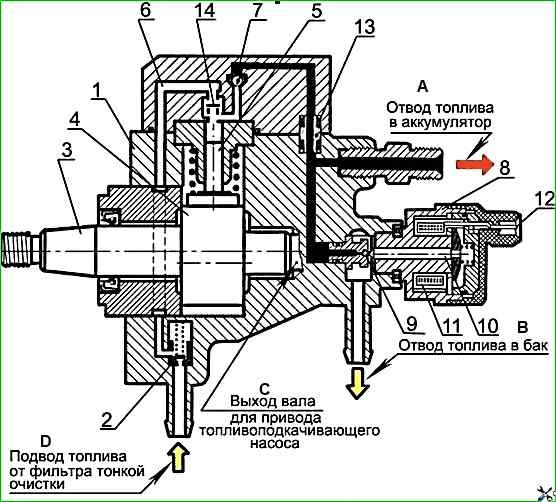

The value of this pressure is maintained at a constant level and can be adjusted by valve 8 (Figure 2) depending on the operating parameters of the diesel engine.

The pressure limiting valve acts as a pressure-reducing (safety) valve.

The valve body on the accumulator side has a channel locked by the cone of the valve core 6.

The spring presses the cone tightly against the valve seat at normal operating pressure, so that the accumulator remains closed.

When the pressure in the accumulator exceeds the operating value, the cone moves away from the seat under the action of pressure and the fuel under high pressure is diverted to the return drain line.

As a result, the fuel pressure in the accumulator decreases.