Steering malfunctions do not always depend on its condition, and are sometimes caused by other reasons

Therefore, before checking and adjusting the steering mechanism, you need to check the wheel balance, air pressure in the tires, the presence of grease in the steering units and wheel hubs, the adjustment of the wheel bearings and steering rods and the correctness of their position, the normal operation of the shock absorbers, the correctness of the installation angles of the front wheels, since all this affects the operation of the steering.

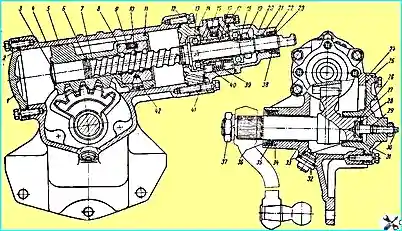

Steering gear: 1 - lower cover; 2, 14, 25, 29 and 41 - sealing rings; 3 - plug; 4 - steering gear housing; 5 - rack-and-pinion piston; 6 - split sealing ring; 7 - steering screw; 8 - ball nut; 9 - groove; 10 - ball; 11 - split piston rings; 12 - intermediate cover; 13 - thrust ball bearing; 15 - ball valve; 15 - spool valve; 17 - control valve housing; 18 - spring washer; 19 - adjusting nut; 20 - upper cover; 21 - needle bearing 22 and 35 - oil seal thrust rings; 23 - outer sealing cuff; 24 - side cover; 26 - thrust washer; 27 - adjusting washer; 28 - retaining ring; 30 - adjusting screw; 31 - pitman arm shaft; 32 - drain plug with magnet; 33 - pitman arm shaft bushings; 34 and 38 - oil seals; 36 - rubber cuff; 37 - pitman arm shaft nut; 39 - reaction spring; 40 - reaction plunger; 42 - adjusting screw

In addition, you should check the oil level in the power steering pump canister and the tension of its belt, as well as whether there is air in the system, sediment or dirt in the tank and on the pump filters, and oil leaks in the pipe connections.

Checking the steering gear adjustments must be done in the following order:

- 1) disconnect the longitudinal steering rod;

- 2) measure with a spring dynamometer attached to the steering wheel rim, the force on this rim in the following three positions:

- - first - the steering wheel is turned more than 2 turns from the middle position, the force on the steering wheel rim should be equal to 0.55-1.35 kg;

- - second - the steering wheel is turned ¾ -1 turn from the middle position, the force should not exceed 2.3 kg;

- - third — the steering wheel passes the middle position, the force on the steering wheel rim should be 0.8-1.25 kg more than the force obtained when measuring in the second position, but not exceed 2.8 kg.

If, when measuring the forces in these positions, they do not correspond to the specified values, then the steering mechanism should be adjusted.

You should start adjusting the steering mechanism by setting the force value in the third position by turning the adjusting screw 30, since this does not require disassembling the steering mechanism.

When turning the screw clockwise, the force will increase, and when turning counterclockwise, it will decrease.

The discrepancy between the forces on the wheel rim in the second position and the above value is caused by damage to the parts of the ball nut assembly, in the first position — by the same reasons, as well as incorrect pre-tensioning of thrust ball bearings 13.

To adjust the force in the first position, the steering gear should be partially disassembled in order to tighten nut 19.