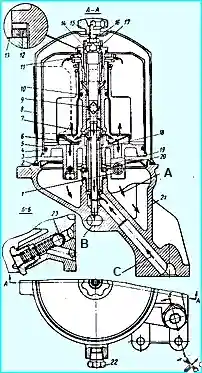

The oil filter (Fig. 1) is centrifugal, with a jet drive, and is included in the lubrication system in series

The oil supplied by the engine pump from the channel through the annular and radial channels enters under the insert 7.

From here, part of the oil through the mesh filter 6, which protects the jets from clogging, is supplied to the two jets 1, and the other part of the oil, having passed through the holes in the insert, is cleaned of dirt in the centrifuge.

The housing 3 of the centrifuge rotates due to the jet force created by the stream of oil flowing out of the housing through the two jets 1.

At an oil pressure of 3-4 kg/cm² the housing together with the oil in it rotates at a speed of 5000-6000 rpm.

Under the action of the resulting centrifugal forces, mechanical particles in the oil are thrown to the side walls of the housing cover 5, where they are deposited, forming a dense sediment.

This sediment is removed from the housing cover when cleaning the centrifuge.

Cleaning filter oils (full-flow centrifuge): 1 - nozzle; 2 - gasket; 3 - housing; 4 - sealing ring; 5 - housing cover; 6 - mesh filter; 7 - insert; 8 - casing; 9 - axle; 10 - insert ring; 11 - retaining ring; 12 - nut gasket; 13 - washer; 14 - nut; 15 - casing fastening nut; 16 - nut; 17 - thrust washer; 18 - axle tube; 19 - ball bearing thrust ring; 20 - thrust bearing; 21 - filter housing; 22 - plug; 23 - bypass valve

The purified oil, having gone around the top of the insert 7, through the radial holes in the upper part of the centrifuge housing 3, the annular channel and the radial holes in the upper part of the axis 9 and the tube 18 enters the housing of the oil filter 21 and then into the distribution chamber of the engine block.

A bypass valve 23 is built into the housing of the filter 21, adjusted for a pressure difference of 0.8-1 kg/cm².

The bypass valve is designed to pass some of the oil into the distribution chamber, bypassing the centrifuge, in case of significant wear of the engine bearings due to increased oil consumption.

Some of the oil can also pass through the bypass valve when starting the engine due to the high viscosity of cold oil.

The rotation of the centrifuge is checked by ear. When the engine stops, a serviceable centrifuge continues to rotate for another 2-3 minutes; a peculiar sound is heard.

The centrifuge must be cleaned simultaneously with the oil change in the engine crankcase.

Previously, a plate-slotted coarse filter was installed, connected to the system in series, and a centrifugal fine filter with a jet drive (centrifuge), connected to the system in parallel.

To clean the centrifuge, you need to stop the engine and let the oil drain from the centrifuge, this takes from 20 to 30 minutes.

Removing the cover 5 of the housing before the centrifuge is completely empty will lead to oil leaking onto the engine.

To clean the centrifuge, you must:

- 1) unscrew the nut 15 of the casing and remove the casing 8;

- 2) unscrew the plug 22 and insert a large punch into the hole that holds the housing from rotation;

- 3) unscrew nut 14 of the cover with a spark plug wrench, remove cover 5. of the housing together with nut 14;

- 4) clean the cover from dirt deposits;

- 5) after cleaning, wash the cover in gasoline or kerosene

- 6) remove the centrifuge insert 7, wash it in gasoline or kerosene;

- 7) remove the mesh filter 6, wash it in gasoline or kerosene and blow it out; if the filter mesh is heavily clogged with gum, if it cannot be cleaned, and also if it is torn, replace the mesh filter;

- 8) clean dirt from gasket 2 of the casing;

- 9) wash the casing 8; damage to the end of the casing adjacent to the gasket 2 is unacceptable, as it leads to oil leakage;

- 10) wash the nut 15 securing the casing.

Assemble in the reverse order.

Install the mesh filter 6 as shown in Fig. 1, ensuring its centering on the flange of the housing 3 of the centrifuge.

Before installing the casing, it is necessary to check whether the centrifuge rotates easily by hand.

Tighten the nut 15 of the casing only by hand.

It is prohibited to unscrew the nut 16 on the centrifuge axis and remove the centrifuge housing from the axis to clean the centrifuge from dirt deposits in order to avoid damage to the sliding bearings of the centrifuge housing.

Only in case of unsatisfactory rotation of the housing 3 on the axis 9, after removing the cover 5 of the housing from the centrifuge, it is necessary to unscrew the nut 16 on the axis, remove the washers and the housing 3 from the axis and check the condition of the axle-bushing unit.

When removing the housing from the axis, it is necessary to take measures to prevent the thrust ring of the ball from falling out bearing 19 into the filter housing 21, if the bushings are clogged, they must be washed in gasoline or kerosene.

At the same time, it is necessary to check the condition of the holes of the jets 1.

If they are clogged, cleaning must be carried out in such a way as not to damage the calibrated hole of the jet.

Install the housing 3 without the cover on the axis 9 in the reverse order.

After cleaning and final assembly, check the rotation of the centrifuge on a warm engine by ear.

In addition to cleaning the oil in the filter, the engine provides for centrifugal cleaning of oil in traps (mud collectors) made in the connecting rod journals of the crankshaft.

Cleaning the oil in the mud collectors is especially effective during the running-in period of the rubbing surfaces. The dirt collectors should be cleaned during engine repairs.