Cylinder head gaskets are replaced when coolant and oil leaks appear at the junction of the cylinder head with the cylinder block.

To perform the work, we will need the following tools: 8x10, 12x13, 17x19, 22x24, 27x30 wrenches, replaceable heads for 13, 14, 17, 19 mm, a ratchet, a ratchet blade, a screwdriver, a chisel, a hammer, a flat scraper, a jack, a stand, a container for fuel, oil and coolant, a torque wrench.

First, disconnect the electrical wires from the batteries.

Drain the coolant.

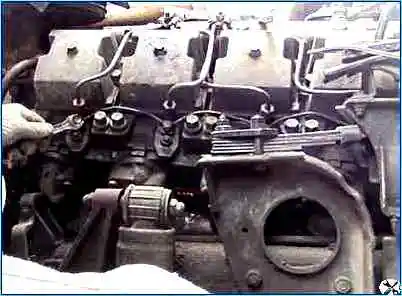

Unscrew the bolts and remove the front crankcase hatch cover clutch.

Lift the front of the car and install a stand under the first cross member of the frame.

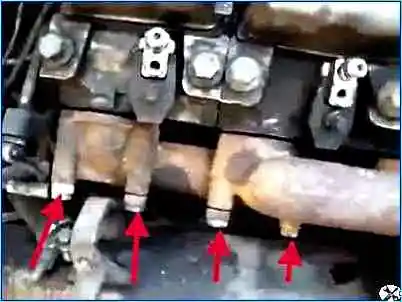

Using a 14 mm head and a wrench, unscrew the drain pipe (return), Figure 1.

Unscrew the high-pressure pipes from the engine injectors.

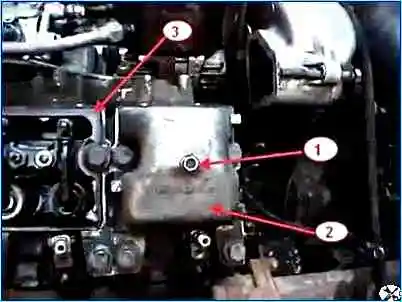

Unscrew the high-pressure pipes from the high-pressure fuel pump, figure 3.

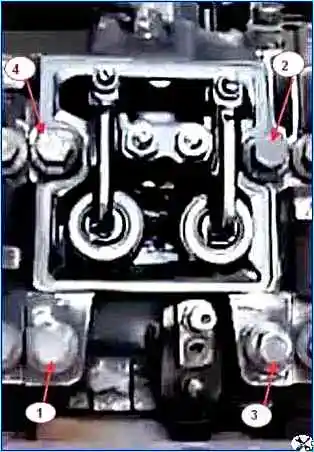

Loosen the tightening of the exhaust manifold mounting bolts (Fig. 4).

Remove the intake manifolds.

Use a 13 mm socket to unscrew the bolts and disconnect the thermostat housing flange.

Unscrew the water pipe mounting bolts and use a mounting blade to separate the pipes from the cylinder heads.

Unscrew bolts 1 (Fig. 5) securing the cylinder head covers and remove covers 2 with gaskets 3.

On the heads of the fourth and eighth cylinders, unscrew the rocker arm strut mounting nuts and remove the struts assembled with the rocker arms and rocker arm clamps and push rods.

Using a 19 mm socket, loosen the cylinder head bolts in the sequence shown in Figure 6, then unscrew them, remove the heads and mark their numbers.

Do not place the head with the mating plane so as not to damage the injector sprayers.

Take out the push rods and lay them in accordance with the cylinder head numbers.

Remove the cylinder head gaskets: sealing and steel for the gas joint.

Clean the mating surfaces of the cylinder heads and cylinder block from carbon deposits and scale.

Installing the cylinder head gaskets

Install the sealing gaskets on the cylinder block.

Install on the upper end of the sleeves new steel cylinder head gaskets (lubricate the steel gaskets with engine oil before installation).

Install the pushrods, screw in the adjusting screws.

Blow out the threaded holes, clean them from dirt and blow with compressed air.

Install the cylinder heads, centering them on the block pins, while ensuring that the adjusting screws of the thermal clearances enter the ends of the rods.

Before screwing in the head bolts, lubricate the threaded part of the bolts with graphite grease mixed with engine oil.

Tighten the head mounting bolts in three steps in the sequence shown in Figure 6:

- - first step - 39.2-49.1 Nm (4-5 kgfm);

- - second step - 117.7-147.2 Nm (12-15 kgfm);

- - third step – 156.9-176.5 Nm (16-18 kgfm).

We adjust the thermal clearances in the valve mechanism. The clearance value for intake valves is 0.25-0.30, for exhaust valves 0.35-0.40 mm.

Install the front clutch housing cover.

Tighten the exhaust manifold mounting bolts.

Install the head covers with gaskets and secure them with bolts and flat washers.

Install the water pipe gaskets, the water pipes assembled with the connecting pipe, tighten with bolts and flat and spring washers.

Attach the thermostat box flange with bolts and flat and spring washers.

Install the intake manifolds and connect the pipes to the heads.

Remove the support from under the front of the car and fill in the coolant.

Connect the electrical wires to the battery.

Start the engine and check the operation of the valve timing mechanism.