Possible malfunctions of the Kamaz heater

Failure of the heater and improper handling of it can cause a fire

Warming up the engine with a heater must be done in the presence of the driver with a working fire extinguisher

To avoid damage to the heater boiler and fire, it is prohibited:

- - turn on the heater without coolant for more than 20 s;

- - pour water into a heater boiler that is overheated due to the lack or lack of coolant;

- - allow the heater to operate with an open flame at the boiler outlet;

- - keep the fuel valve on the tank open when the heater is not working.

During the operation of the vehicle, contamination of the heater, leakage of fuel and coolant in the connections of pipelines, hoses and taps are not allowed.

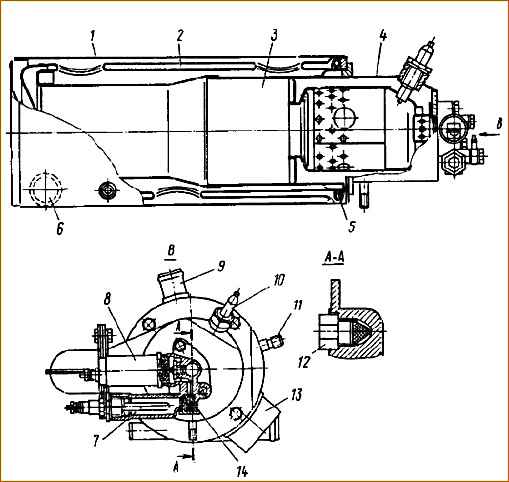

Heater heat exchanger: 1- heat exchanger; 2 - return gas duct; 3 - straight gas duct; 4 - burner; 5 - gas fuel heater; 6-fluid supply pipe: 7 - electric fuel heater; 5 – electromagnetic valve; 9 - pipe for draining liquid from the heat exchanger; 10 - electric spark plug; 11 – fitting for supplying fuel to the heater in the heat exchanger; 12 - nozzle; 13 - exhaust gas outlet pipe; 14 – fuel filter

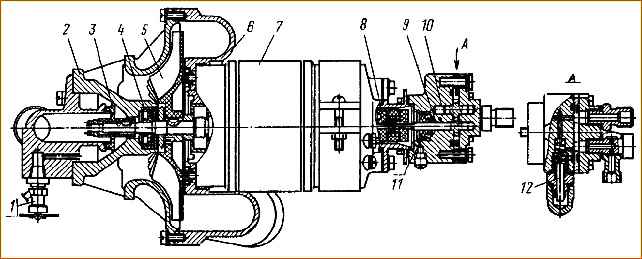

Pumping unit: 1 - drain tap; 2 - liquid pump housing; 3 - working wheel of the liquid pump; 4, 11 - sealing cuffs; 5 - fan impeller; 6 - fan housing; 7 - electric motor; 8 - fuel pump coupling; 9 - fuel pump drive gear; 10 – fuel pump driven gear; 12 - pressure reducing valve

For seasonal maintenance

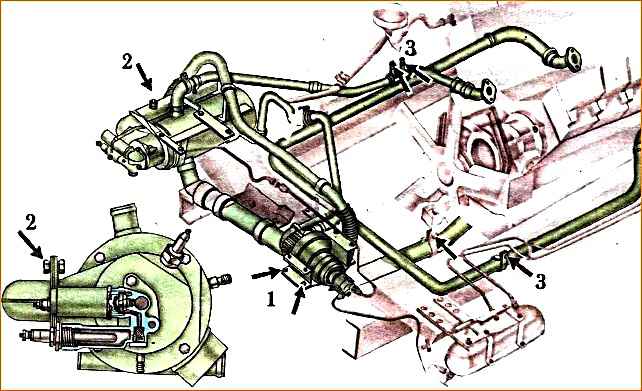

Secure the pump unit, heat exchanger, pipes, pre-heater outlet pipe

- Tightening torque of the pump unit mounting bolts – 44-53 Nm (4.5-5.4 kgcm);

- The tightening torque of the heat exchanger mounting bolts is 44-53 Nm (4.5-5.4 kgcm);

- The tightening torque of the M10 bolts of the pipe is 44-53 Nm (4.5-5.4 kgcm); exhaust pipe bolts - 15-25 Nm (1.5-2.5 kgcm)

In the fall, during seasonal maintenance, the spark plug should be cleaned of carbon deposits;

- - remove the burner and use a metal brush to clean the combustion chamber and flue from carbon deposits, blow with compressed air;

- - remove and wash the filters of the solenoid valve and injector, the protective mesh of the fuel valve of the tank;

- - disassemble and wash the nozzle. After assembly, check the operation of the heater.

Normal operation of the heater is determined by the uniform hum of combustion in the boiler and the release of exhaust gases without smoke or open flame.

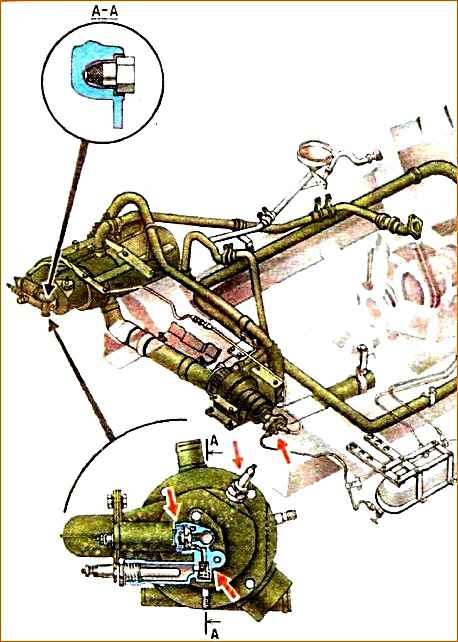

If necessary, adjust the fuel consumption using the pressure reducing valve of the fuel pump in the following order:

- - unscrew the cap nut on the fuel pump; loosen the locknut of the adjusting screw;

- - by turning the adjusting screw to the right (fuel supply increases) or to the left (fuel supply decreases), adjust the heater operating mode.

After completing the adjustment, lock the adjusting screw with the locknut and screw on the cap nut.

To ensure normal operation of the heater, the fuel pump pressure reducing valve should be adjusted at negative ambient temperatures (not higher than - 5°C).

After washing the car or fording in the cold season, you should remove the water that has entered the air duct of the fan by turning on the pump unit for 3-4 minutes. To do this, move the switch knob to position III.

During the operation of the heater, some malfunctions may arise that can be eliminated during the process of servicing the heater; many of them can be eliminated by the drivers themselves, who have the appropriate training.

The following malfunctions occur most often

the heater smokes during operation

As a rule, this is a consequence of a large fuel supply due to a maladjustment of the fuel pump pressure reducing valve.

The malfunction is eliminated by regulation. Another reason for the appearance of smoke is the low speed of the electric motor when it malfunctions or the batteries are discharged.

In such cases, it is necessary to replace the electric motor or charge the batteries.

An open flame is observed in the combustion chamber of the heater

The reason is untimely removal of carbon deposits.

Having disassembled the heater boiler, clean off the carbon deposits.

Engine warm-up time is long

There are several reasons for this: clogging of fuel lines, filters, injectors, as well as a malfunction of the electrical system.

When the heater is turned on in position III, the fan operation cannot be heard

The reason is water getting into the fan or freezing of the liquid pump.

In both cases, the fan and liquid pump casing should be warmed up, taking precautions.

Another reason is damage to the wiring or electric motor of the pump unit.

When the switch key is set to position I, the fuel does not ignite

The reason is an open circuit, a short circuit in the power wires of the switch and coil.

You can detect a malfunction using a control lamp or tester.

Another reason is damage to the induction coil or spark plug. Check them separately and replace them if there is no spark. Sometimes a damp coil needs to be dried.