If an oil leak through the oil pan gasket cannot be eliminated by tightening its mounting bolts, it means that the gasket is severely deformed and must be replaced

Carry out the work on a lift or inspection pit.

You will need keys 12,14,17 (socket heads), extension, cardan joints.

Remove the engine splash guard.

Drain the oil.

Using a 14mm socket, unscrew the four bolts securing the clutch housing amplifier to the block.

Using wrenches 14 and 17, unscrew the two bolts securing the amplifier to the clutch housing

Unscrew the nut of the oil cooler drain hose and disconnect the hose from the oil sump fitting and remove the amplifier.

We unscrew the four nuts with a 13mm socket and the eleven bolts securing the crankcase to the cylinder block with a 12mm wrench.

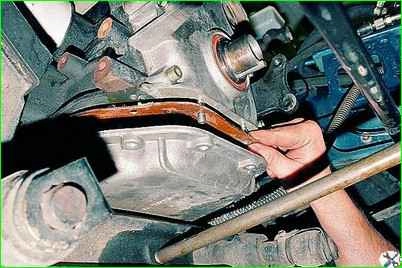

Carefully, trying not to damage the gasket, remove the pallet from the studs and place it on the beam.

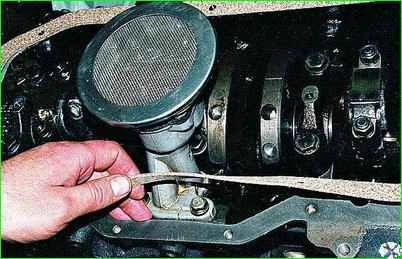

Remove the gasket from the cylinder block studs.

Before installing a new gasket, degrease the pressure surface of the oil sump and cylinder block, then install the gasket in place.

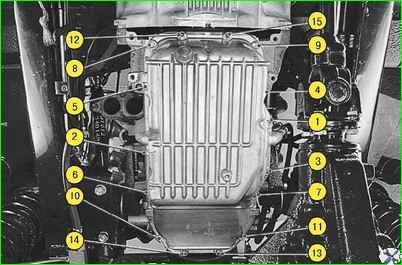

Install the oil pan and tighten the bolts and nuts securing it to the cylinder block evenly in a crisscross pattern as shown

Install the removed parts in the reverse order of removal.

Fill the engine with oil.