Removing the throttle assembly

We remove the throttle assembly to replace the idle speed controller or the throttle assembly gasket. Disconnect the negative cable from the battery.

Partially drain the coolant.

Using a Phillips screwdriver, loosen the clamp securing the air hose to the throttle assembly.

Disconnect the air hose.

Loosen the clamp and remove the crankcase ventilation hose from the throttle assembly fitting.

We loosen the clamps with pliers.

We remove the supply and coolant outlet.

After loosening the clamp, remove the adsorber hose from the fitting.

Disconnect the throttle position sensor and idle speed control connectors.

Disconnect the cable from the throttle drive pulley.

Using a 13 mm socket with an extension, unscrew the two nuts securing the throttle assembly to the receiver.

Removing the throttle assembly

The connection is sealed with a gasket

A plastic bushing organizes the air flow in the receiver.

The flat on the bushing should face the flat surface of the receiver

Install the throttle assembly in the reverse order.

Tightening torque of the nuts is 15–20 Nm.

Add coolant.

Removing the idle speed control valve

Remove the throttle assembly.

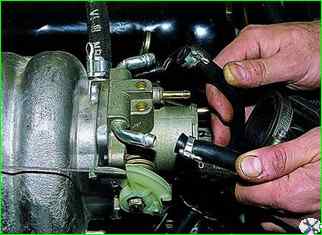

Using a Phillips screwdriver, unscrew the two screws securing the valve to the throttle assembly.

Remove the idle speed control valve.

The connection is sealed with a rubber ring.

Install the idle speed control valve in the reverse order.

For a new regulator, use a caliper to check the distance between the end of the valve needle and the mounting flange: it should be no more than 23 mm.

This is necessary to avoid damaging the regulator during installation — the regulator needle should not rest against the throttle seat.

Before installing the regulator, clean the valve seat, air channel, and surface under the regulator sealing ring in the throttle assembly.

Lubricate the regulator sealing ring with engine oil. The tightening torque of the regulator mounting screws is 3–4 Nm.