Disconnect the wire from the negative terminal of the battery.

Remove the distributor cap.

Rotate the crankshaft until the compression stroke begins.

To determine this moment, you need to unscrew the spark plug of the 1st cylinder and close the hole for the spark plug with your finger.

At the beginning of the compression stroke, air will begin to escape from under the finger.

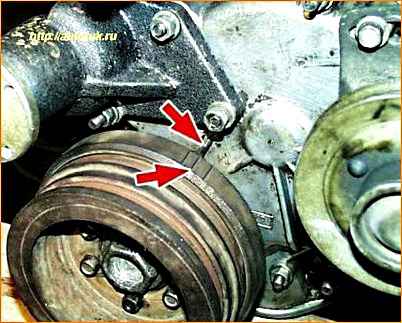

Carefully rotate the crankshaft until the second mark on the pulley coincides with the boss on the camshaft sprocket cover.

This mark corresponds to an ignition timing angle of 5° on an engine with an exhaust gas recirculation system (for engines without exhaust gas recirculation systems, install the pulley so that the middle of the pulley between the second and third marks is against the tide on the camshaft sprocket cover, which corresponds to the ignition timing 2°).

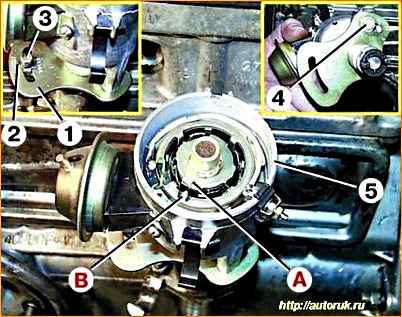

Loosen bolt 3 securing the distributor. Set pointer 2 of the octane corrector to the middle of scale 1 and tighten bolt 3.

Loosen bolt 4 securing the octane corrector plate to the distributor body.

Lightly press the slider with your finger against its rotation (clockwise) to select the gaps in the drive.

Holding the slider, slowly turn the distributor housing 5 until the red mark “A” on the rotor aligns with the arrow “B” on the stator.

Tighten bolt 4 securing the octane corrector plate to the distributor body.

Install the distributor cap and connect the high-voltage wires in accordance with the operating order of cylinders 1—2—4—3.

Check the ignition timing setting.

To do this, warm up the engine to a temperature of 80-90 °C and, moving on a flat road at a speed of 30-40 km/h, sharply press the accelerator pedal all the way.

In this case, detonation should be heard briefly.

If detonation is not audible, it means the ignition is late.

If the detonation is too strong, it means the ignition is early.

When ignition is early, turn the distributor body one scale division towards “+” (counterclockwise), and when ignition is late, turn towards “—” (clockwise).

Then check the ignition timing again while the car is moving, as described above.

A more precise setting of the ignition timing can be done using a strobe light in accordance with the instructions included with the strobe light.