Adjust the bearings carefully.

If the bearings are loosely tightened during movement, impacts occur that destroy the bearings.

If the tightening is too tight, the bearings become very hot, causing the lubricant to leak out and the bearings to fail.

Adjust the bearings in the following order:

Raise the wheel whose bearings need to be adjusted with a jack.

Remove the rear axle axle shaft (or the drive flange of the hub with the front axle wheel release clutch). To do this, tighten the two puller bolts.

Bend the lock washer tab, unscrew the lock nut, and remove the lock washer.

Unscrew the bearing adjustment nut 1/6–1/3 turns (1–2 edges).

Turn the wheel by hand and check that it rotates easily.

In case of tight rotation, eliminate the cause of braking (for example, the drum hitting the brake pads, cuffs sticking, etc.).

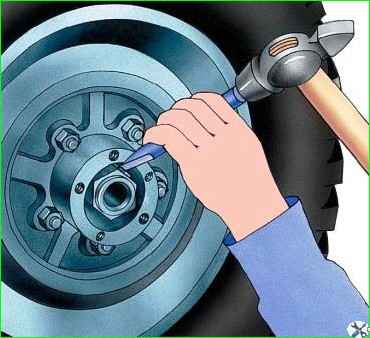

Tighten the hub bearing adjustment nut using a wrench (Fig. 1) and a 300–350 mm long wrench with one hand until the wheel rotates tightly.

When tightening the nut, press the wrench knob smoothly, without jerking, and turn the wheel to correctly position the rollers on the bearing ring raceways.

Unscrew the nut 1/4–1/3 turn (1.5–2 edges), install the lock washer.

Tighten the locknut and lock both nuts, bending the washer's whiskers at the edge of the nut and locknut (Fig. 2).

Check the bearing adjustment after tightening the locknut.

When adjusted correctly, the wheel should rotate freely, without jamming, noticeable axial play or rolling.

Reinstall the rear axle axle shaft (or the drive flange and front axle wheel release clutch), install the bolts with spring washers and tighten.

Tightening torque 60–70 Nm (6–7 kgf m).

Check the bearings for correct adjustment by checking the heating of the wheel hub when driving.

If the hub gets very hot, unscrew the nut 1/6 turn (1 edge), following the sequence and rules outlined above.

When checking the adjustment of bearings for heating the hubs, do not use the service brakes, since in this case the hubs are heated by the brake drums.