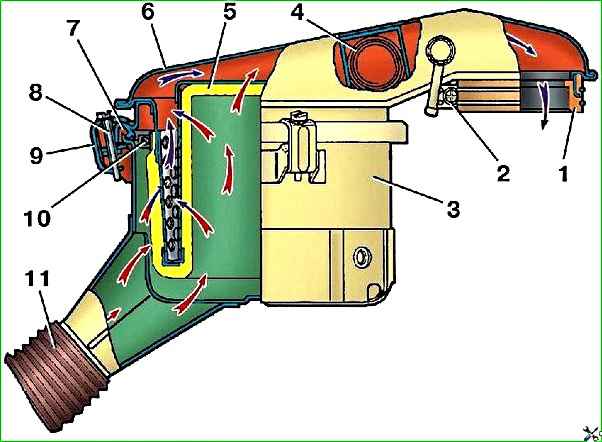

The air filter (Fig. 1) is a dry type with a replaceable filter element made of synthetic non-woven material, installed on the engine on the right side in front of the carburetor and connected to the latter using a rubber coupling, secured to the carburetor with a wire clamp

Maintenance of the air filter consists of visual inspection and cleaning of the filter element from contamination, replacing it if there are breaks or burns.

The filter element can be cleaned no more than 15 times using the following methods:

- rinse with water with the addition of synthetic detergents, followed by rinsing, lightly squeezing and drying; blow out or clean by shaking.

Make sure to replace the filter element:

- - in the presence of breakthroughs or burns; after 100,000 km;

- - when the maximum allowed number of cleaning times is reached.

To replace or clean the filter element you must:

- - loosen bolts 8 and clamp 2;

- - move staples 9;

- - remove cover 6 with filter element 5;

- - remove clamp 10 and pull off the filter element from the frame.

Assemble the filter in reverse order. Do not operate the filter with flame arrester 4 removed, seal 7 and coupling 1 damaged.

Intake pipe maintenance

Periodically clean its internal surfaces of tarry deposits, as deposits reduce the flow areas of the intake channels and lead to a drop in engine power.

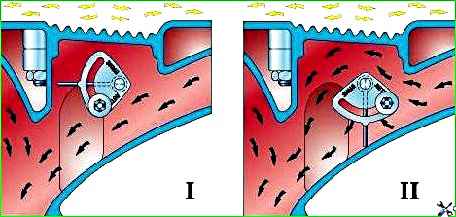

For seasonal maintenance, install the damper (Fig. 2) in the position corresponding to the upcoming time of year.