If there are scoring marks, deep scratches and other defects on the working surface of the disc that increase pad wear and reduce braking efficiency, as well as in the case of increased lateral runout of the disc, causing vibrations during braking, replace the disc

In specialized workshops, such a disc can be turned and ground on both sides to the same depth, but after processing, the thickness of the disc must not be less than the minimum permissible.

The minimum permissible thickness of the brake disc is 9.5 mm. If the thickness of the disc is less, it must be replaced.

The axial runout of the brake disc surface must not exceed 0.15 mm.

You will need: wrenches "10", "14", "17", "27" (preferably a head with a strong handle), pliers, a punch, a screwdriver, a hammer.

Remove the caliper (see "How to repair the front wheel brake mechanism of the Niva Chevrolet") without disconnecting the brake hose from it.

Hang the caliper on a rope or wire, while making sure that the brake hose is not twisted and is not too tight.

Remove the brake pads.

Mark them so that they can be installed in their original places during assembly.

Unscrew the bolt securing the casing.

Use a screwdriver to bend back the tab of the locking plate of the upper and lower bolts securing the shoe guide to the swivel fist

Unscrew the lower and upper bolts securing the brake shoe guide

Unscrew the upper bolt with a head on 17

Remove the casing.

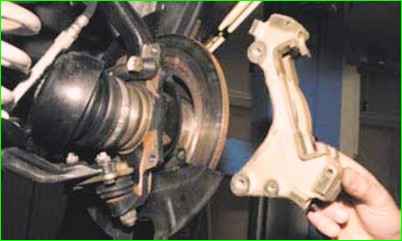

Remove the guide pads.

Unscrew the hub nut.

Remove the hub assembly with the brake disk

Screw the nuts onto the studs so as not to damage the threads of the studs, and knock out the studs (one is shown in the photo).

Tap the edge of the hub with a hammer to separate the hub and brake disc

Install the new brake disc and the removed parts in the reverse order of removal.

In this case, do not forget to lock the brake shoe guide mounting bolts by bending the tabs of the locking plates.

Before installing oh disk, thoroughly clean the mating surfaces of the hub and disk from rust and scale, since the smallest particle of them, clamped between the mating surfaces, will cause the disk to beat and vibration during braking.

If you are installing the old disk, remove the ribs on the working surfaces of the disk with a file, formed as a result of disk wear on both sides.

To press back the previously pressed studs, you can use the wheel mounting nuts.

Screw them onto the ends of the studs through the spacers (you can use larger nuts as spacers) and tighten evenly in a crisscross pattern until the studs are fully pressed into the disc and hub.