The main faults that require the removal and disassembly of the clutch to fix:

- – increased (compared to usual) noise when engaging the clutch;

- – jerks when the clutch is operating;

- – incomplete engagement of the clutch (the clutch "slips");

- – incomplete disengagement of the clutch (the clutch "leads").

The work of removing and installing the clutch is very labor-intensive, so first make sure that the faults are not caused by defects in the clutch drive.

If after disassembling the clutch no obvious signs of malfunction of individual components are found, replace all components at the same time.

Since the gearbox must be removed before removing the clutch, work with an assistant.

You will need: a key "8", two screwdrivers, a drift for centering the driven disk (can be made from the primary shaft of the gearbox by removing the gear).

Place the car on an inspection pit or lift.

Remove the gearbox (see "How to replace the gearbox of a Niva Chevrolet").

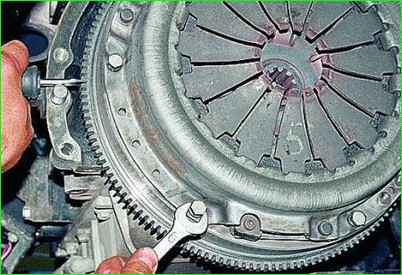

If you are going to install the old pressure plate, mark in any way (for example, by punching) the relative position of the disc housing and the flywheel in order to install the pressure plate in the same position (to maintain balance).

Unscrew the six bolts securing the pressure plate to the flywheel, holding the flywheel from turning with a mounting blade.

Remove the pressure and driven disks, holding the driven disk.

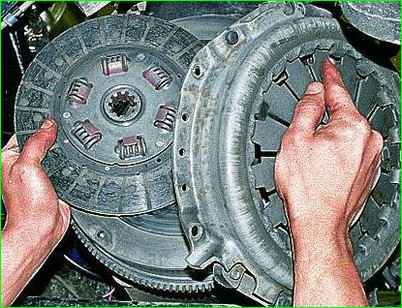

Inspect the driven disk.

Cracks on the driven disk parts are not allowed.

Check the wear of the friction linings.

If the rivet heads are recessed less than 0.2 mm, and the surface of the friction linings is oily or the rivet joints are loose, then the driven disk (or friction linings) must be replaced.

Check the reliability of the fixation of the damper springs in the sockets of the hub of the driven disk.

If the springs are broken, replace the disk.

Check the runout of the driven disk, if its warping is detected during visual inspection.

If the runout value exceeds 0.5 mm, replace the disk.

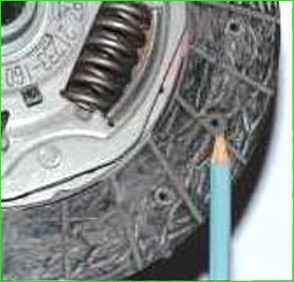

Externally inspect the condition of the diaphragm spring of the pressure plate.

Cracks on the diaphragm spring are not allowed.

The points of contact of the spring petals with the clutch release bearing must be in the same plane and have no obvious signs of wear.

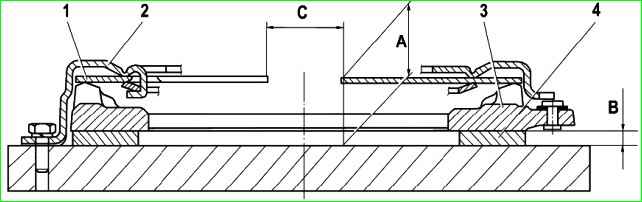

Checking the condition of the clutch pressure plate assembly

Fasten the pressure plate 3 (Fig. 7) together with the pressure spring 1 and the casing 2 on the device with the intermediate ring 4 of thickness B=(8.3+0.01) mm.

This device replaces the flywheel with the driven disk.

Check by disengaging the clutch three times with a disengagement stroke of 8–9 mm, applying a load to the petals of the pressure spring 1 at a diameter of C=34 mm. In this case:

- – check that the release stroke (8.0+0.1) mm corresponds to a stroke of the pressure plate of at least 1.4 mm;

- – the difference in the values of the travel of the pressure plate 3 is no more than 0.25 mm;

- – the dimension "A" must be within (35.7+1) mm;

- – the load on the petals of the pressure spring 1 on the diameter C with a stroke of (8.0+0.1) mm must be no more than 1330 N, peak release load no more than 1720 N.

Measure the depth of the annular wear of the pressure spring petals at the point of contact with the clutch release bearing, if the wear exceeds 0.8 mm, replace the clutch housing assembly with the pressure plate.

Install the clutch in the reverse order of removal.

Before tightening the pressure plate mounting bolts, carefully center the drive disk mandrel.

If this is not done, the installation of the gearbox will be difficult.