Remove the oil pump if a defect occurs - decreased oil pressure

A decrease in pressure may be due to clogging of the oil receiver.

It is also possible that the pressure may decrease due to a malfunction of the pressure relief valve, wear of the pump parts itself.

If the oil receiver mesh is clogged, then wash it and blow it out.

Before removing the oil receiver, you need to remove the engine sump.

The oil sump also needs to be removed when replacing the gasket.

Place the car on an inspection ditch or on a lift.

Disconnect the inlet pipe from the exhaust manifold.

Remove the rear support of the power unit.

Unscrew the three screws securing the front bumper to subframe.

Unscrew the rear subframe mounting bolts by about 4 turns.

Having unscrewed the bolts securing the two subframe brackets to the body and the front subframe mounting bolts, lower the front part of the subframe on the adjustable stand.

Using a 13 mm head, unscrew the nut securing the power steering tube bracket to the cylinder block, holding the bolt from turning with a 13 mm wrench.

Using a 13 mm head, unscrew the bolt securing the power steering pipe bracket to the cylinder block bracket

Take a 13 mm head and unscrew the bolt securing the oil pan to the cylinder block bracket.

On the left side, use a 10 mm wrench to unscrew the bolt securing the power steering tube bracket to the subframe.

Move the power steering pipe away from the subframe

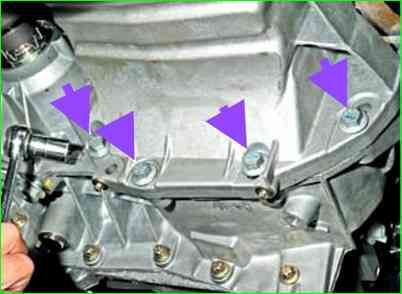

Using a 13 mm socket, unscrew the four bolts securing the oil pan to the gearbox

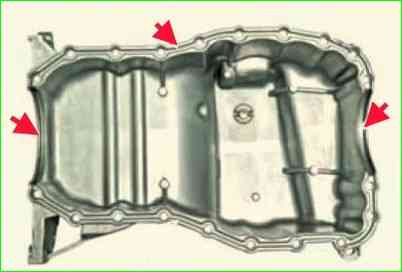

Using a 10 mm socket, unscrew the 20 oil pan mounting bolts.

Pull the subframe down and remove the oil pan. We take it out of the subframe.

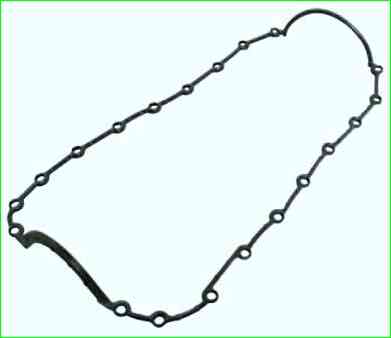

We take out the sealing gasket from the grooves of the oil pan.

We thoroughly clean the surfaces of the pan and crankcase.

Apply a thin layer of sealant.

Install a new gasket in the groove of the pan.

Apply a thin layer of sealant in the area of the cylinder block cover ndrov

Also apply a thin layer of sealant in the area of the first main bearing cap

Install the oil pan and tighten the mounting bolts

Tighten the bolts according to the diagram with a tightening torque:

- - Stage 1 - 8 Nm;

- - Stage 2 - 44 Nm.

Removing the oil pump

After removing the oil pan, use a 13 head to unscrew the two bolts securing the oil pump to cylinder block.

We remove the pump sprocket from engagement with the chain

We remove the pump.

Before installation, clean all surfaces from oil residues.

We install the pump in the reverse order. We tighten the pump mounting bolts with a torque of 25 Nm.