This article describes the diagnostic procedure used for the air conditioning system of the LADA LARGUS car

Necessary diagnostic equipment and devices:

- - DST-12 diagnostic device (RF90 firmware);

- - multimeter;

- - universal contact board.

General instructions for diagnostics

To diagnose the air conditioning system, it is necessary to connect the diagnostic device, turn on the ignition and perform the necessary operations (check for faults, check the compliance of data transmitted by the controller) related to the air conditioning system, in accordance with the requirements of TI 3100.25100.12041 "Diagnostics of the ECU of the LADA LARGUS car".

Troubleshooting algorithm (APN)

If no faults are detected during the check using the diagnostic tool, but the fault remains, then the corresponding ANP should be used to eliminate the fault.

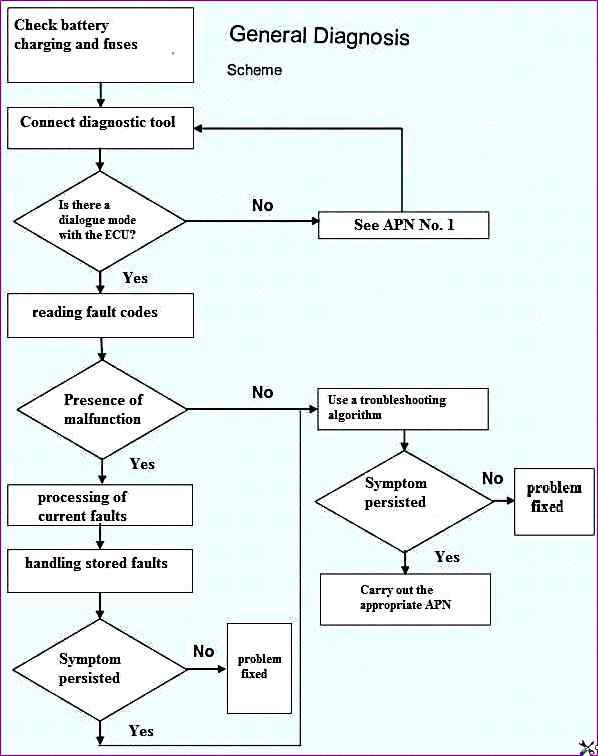

The general flow chart for performing diagnostics is shown in Figure 1 as a block diagram.

Checking the wiring

Difficulties in diagnostics

By disconnecting the connectors and/or moving the wire harnesses, the cause of the fault can be eliminated instantly.

Voltage measurements, resistance and insulation resistance usually give correct values of the measured values, especially if the fault is not present (memorized) at the time of testing.

Visual inspection

Look for signs of damage in the engine compartment and the passenger compartment.

Carefully check the protective covers, the integrity of the insulation and the correct routing of the wire harnesses.

Look for signs of oxidation.

Check by touch

When wiggling and twisting the wire harnesses, use a diagnostic tool to determine the moment the fault transitions from the "stored" state to the "current" state.

Make sure the connectors are securely fixed.

Slightly "wiggle" the connectors.

Twist the wire harness.

If the fault state has changed, try to establish its reason.

Checking individual elements

Disconnect the connectors and check the condition of the clamps and contacts, as well as their crimping (there should be no traces of crimping on the insulation).

Check that the clamps and contacts are securely fixed in the connector sockets.

Make sure that the clamps and contacts are not squeezed out when connecting the connector.

Check the contact pressure of the clamps using a contact terminal of the appropriate type.

Checking the resistance

First check the integrity of the entire circuit, then in individual sections. Determine if there is a short circuit to ground, to +12 V or to another wire.

If a fault is detected, fix it or replace the wiring.

Troubleshooting algorithms:

- Faults detected during operation of the air conditioning system - ALP number

No communication with the ECU - ALP 1

No cooling - ALP 2

Insufficient cooling - ALP 3

Increased compressor noise - ALP 4

High discharge pressure - ALP 5

Low discharge pressure - ALP 6

Before starting the troubleshooting, it is necessary to check the ECU using a diagnostic tool according to requirements

TI 3100.25100.12041 "Diagnostics of the ECU of the LADA LARGUS car" for the presence of fault codes related to the operation of the air conditioning system.

Decoding

APN 1 - No communication with the ECU

No diagnostic instructions

Make sure that the diagnostic device is not the cause of this malfunction by checking it when establishing communication with the ECU on another car.

If the device is not the cause of this malfunction, but the dialogue mode is not established with any other ECU of the same car, it is possible that the possible cause is a malfunction of one of the ECUs, which disrupts the operation of the diagnostic

K-line

Sequentially disconnect the ECU connectors to determine which one faulty.

If necessary, correct the fault.

Check the battery voltage and perform the necessary work to obtain the correct voltage (9.5 V < battery voltage < 17.5 V).

Check for 12 V at pin "16" of the diagnostic connector.

If necessary, correct the fault in the circuit before the fuse.

Check for ground at pins "4" and "5" of the diagnostic connector.

If necessary, correct the fault.

Using the universal contact plate, check for open and short circuits in the cepah:

- - ECU ECM, terminal "28" - "ground";

- - ECU ECM, terminal "33" - "ground";

- - ECU ECM, terminal "3" - "ground";

- - ECU ECM, terminal "56" - terminal "7" of the diagnostic connector;

- - ECU ECM, terminal "26" - terminal "15" of the diagnostic connector;

- - ECU ECM, terminal "29" - fuse;

- - ECU ECM, terminal "30" - fuse.

If necessary, eliminate the fault.

After eliminating the fault, check the system using a diagnostic tool.

APN 2 - No cooling

Diagnostic instructions

Perform after a complete check of the air conditioning system using a diagnostic tool.

- The heater fan is not working

Make sure the heater fan is working:

- - check the serviceability of fuses F36 and F39;

- - check the serviceability of the additional resistor;

- - check the serviceability of the electrical wiring;

- - check the serviceability of the heating, air conditioning and ventilation control unit.

If necessary, troubleshoot, replace faulty components.

- The compressor is not working

Check the serviceability of fuse F01;

Check for an open or short circuit in circuits:

- - heating, air conditioning and ventilation control unit, terminal "5" - terminal "46" of the ECM;

- - fuse F01, terminal "S" - terminal "B3" of the air conditioning compressor relay;

- - air conditioning compressor relay, terminal "B5" - terminal "1" of the air conditioning electromagnetic clutch;

- - air conditioning compressor relay, terminal "B2" - terminal "10" of the ECM;

- - air conditioning compressor relay, terminal "B1" - terminal "A5" of the actuator relay;

If necessary, troubleshoot.

Check the serviceability of the compressor electromagnetic clutch.

If necessary, replace the compressor.

- Insufficient amount of refrigerant in system

Make sure there is enough refrigerant in the air conditioning system:

- - check the refrigerant charge level;

- - make sure there are no refrigerant leaks.

If necessary, eliminate refrigerant leaks, restore the refrigerant level.

APN 3 - Insufficient cooling

Diagnostic instructions

Perform after a complete check of the air conditioning system using a diagnostic tool.

- Clogging of the air filter of the ventilation cabin

Make sure there is no contamination on the surface of the air filter of the ventilation cabin.

If necessary, clean or replace the ventilation cabin filter.

- The fan does not work heater

Make sure the heater fan is working:

- - check fuses F36 and F39;

- - check the serviceability of the additional resistor;

- - check the serviceability of the electrical wiring;

- - check the serviceability of the heating, air conditioning and ventilation control unit.

If necessary, troubleshoot, replace faulty components.

- Slippage of the accessory drive belt

Make sure there is no slippage of the accessory drive belt.

If necessary, replace the accessory drive belt.

- Condenser contamination

Make sure there is no contamination on the condenser surface.

Clean the condenser if necessary.

- Insufficient refrigerant in the system

Make sure there is enough refrigerant in the air conditioning system:

- - check the refrigerant charge level;

- - make sure there are no refrigerant leaks.

If necessary, eliminate refrigerant leaks, restore the refrigerant level.

- Thermostat expansion valve (TXV) is faulty

Make sure there is enough refrigerant in the air conditioning system:

- - check that the TXV is installed correctly;

- - check if the TXV is dirty or jammed;

- - check if the TRV mesh is clogged;

- - make sure there is no leak in the TRV bulb;

- - make sure that the TRV valve opens and closes.

Replace the TRV if necessary.

- Icing of the evaporator

Make sure the heater fan is working:

- - check the serviceability of fuses F36 and F39;

- - check the serviceability of the additional resistor;

- - check the serviceability of the electrical wiring;

- - check the serviceability of the heating, air conditioning and ventilation control unit.

If necessary, troubleshoot, replace faulty elements.

Convince be free of contamination on the evaporator surface:

If necessary, clean the evaporator.

Make sure the receiver-drier is not clogged.

If necessary, replace the receiver-drier.

Make sure there is no moisture in the system.

If necessary, perform the following procedure:

- - discharge the refrigerant from the system;

- - replace the receiver-drier;

- - drain and charge the system.

- The receiver-drier dehydrator is clogged

Make sure the receiver-drier is not clogged.

If necessary, replace the receiver-drier.

- Presence of air and non-condensable gases in the system

Make sure there is no air and non-condensable gases in the system.

If necessary, bleed air and non-condensable gases from the system.

- Faulty compressor valves

Make sure the compressor valves are in good condition

Replace the compressor if necessary.

After troubleshooting, check the air conditioning system

APN 4 - Increased compressor noise

Diagnostic instructions

Perform after a complete check of the air conditioning system using a diagnostic tool.

- Insufficient or excess oil in the system

Check the oil level in the system air conditioning.

If necessary, top up the oil level to normal.

- Excessive amount of refrigerant in the system

Check the refrigerant level in the air conditioning system.

If necessary, discharge excess refrigerant from the system.

- Faulty or low supply voltage of the compressor electromagnetic clutch

Measure the supply voltage of the compressor electromagnetic clutch.

Check the reliability of the connections in the electrical wiring.

If necessary, eliminate the faults, replace the compressor.

- Loose compressor mounting elements

Make sure that the compressor mounting elements are securely fastened.

Tighten the compressor mounting bolts if necessary.

- Compressor parts are worn or broken

Check that there is no wear or breakage of compressor parts.

Replace the compressor if necessary.

After troubleshooting, check the air conditioning system

APN 5 - High discharge pressure

Diagnostic instructions

Carry out after a complete check of the air conditioning system using the diagnostic tool, and if the PR037 "Refrigerant pressure" parameter is above the maximum permissible value (> 6 bar).

- High ambient temperature

Make sure that the ambient temperature does not exceed +45°C.

If necessary, test the system in a room with an air temperature of up to 45°C.

- Excessive amount of refrigerant in the system

Check the refrigerant level in the air conditioning system.

If necessary, discharge excess refrigerant from the system.

- Condenser contamination

Make sure there is no contamination on the condenser surface.

If necessary, clean the condenser.

- The engine cooling fan does not work

Make sure the cooling fan is working properly engine:

- - check the fuses for serviceability;

- - check the additional resistor for serviceability;

- - check the wiring for serviceability;

If necessary, troubleshoot and replace faulty elements.

- The heater fan does not work

Make sure the heater fan is working:

- - check the fuses F36 and F39 for serviceability;

- - check the additional resistor for serviceability;

- - check the wiring for serviceability;

- - check the heating, air conditioning and ventilation control unit for serviceability.

If necessary, troubleshoot and replace faulty elements.

- Availability air and non-condensable gases in the system

Make sure there is no air or non-condensable gases in the system.

If necessary, bleed air and non-condensable gases from the system.

After troubleshooting, check the air conditioning system

ALP 6 - Low discharge pressure

Diagnostic instructions

Carry out after a complete check of the air conditioning system using the diagnostic tool, and if the PR037 "Refrigerant pressure" parameter is below the minimum permissible value (< 2 bar).

- Insufficient amount of refrigerant in the system

Make sure there is enough refrigerant in the air conditioning system:

- - check the refrigerant charge level;

- - make sure there are no refrigerant leaks.

If necessary, eliminate refrigerant leaks, restore the refrigerant level.

- Low ambient air temperature

Make sure that the ambient air temperature is not lower than +10°С.

If necessary, test the system in a room with an air temperature above +10°С.

- Auxiliary drive belt slippage

Make sure that the auxiliary drive belt does not slip.

Replace the auxiliary drive belt if necessary.

- Compressor valves are faulty

Make sure compressor valves are working properly

Replace compressor if necessary.

After troubleshooting, check air conditioning system