Replacing the threaded joints of the front suspension strut of the GAZ-3110

Install the car on a lift or inspection ditch

Clean the mounting points of the levers from dirt.

Loosen the wheel mounting bolts.

If the car is parked in a ditch, then put the car on the parking brake, put chocks under the rear wheels, lift the front of the car and place it on supports.

Remove the wheel

Install a jack (preferably hydraulic) under the spring cup and, using it to lift the cup, load the spring.

If the car is installed on a lift, first remove the wheel, and then place a stable support under the spring cup and, carefully lowering the car, load the spring.

Remove the brake disc.

Unscrew the two bolts securing the steering linkage swing arm to the steering knuckle.

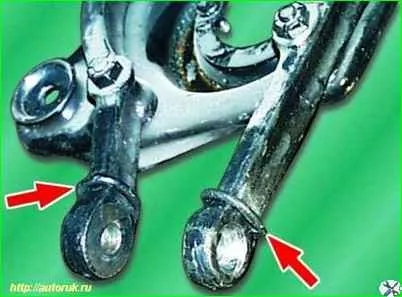

Disconnect the upper arms and lower arms from the strut. Remove the steering knuckle and strut assembly.

For ease of installation, place rubber bushing seals on the ends of the levers.

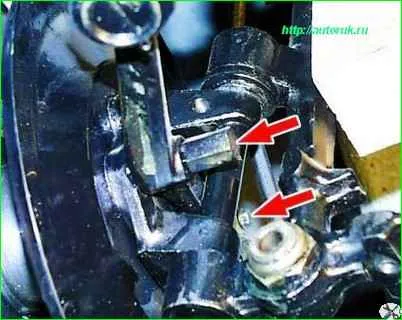

Screw spacer 2 into threaded bushing 1 so that the ends of the bushings are flush with the side of the threaded bushing opposite the hexagon (arrow A).

Insert a wide-head bolt into the hole in the spacer sleeve and press the outer sleeve out of the strut head, applying force to the bolt head (in the direction of arrow A).

Carefully clean the rack head from dirt.

Unscrew the grease fitting from the rack head, clean the channel for lubrication of the threaded joint with soft wire and blow with compressed air.

Press in a new threaded bushing using a mandrel, applying force to the hexagon of the bushing.

In this case, it is necessary to align the lubrication holes in the bushing and the strut head.

Screw the spacer into the threaded sleeve so that its ends protrude to the same length on both sides.

Then installation work should be carried out in the reverse order of disassembly.

In this case, the heads of the fingers should be directed forward along the direction of the car.

It should be borne in mind that the final tightening of the threaded connections of the lever mounting is carried out only on the suspension, which is in a loaded state.

Tightening torques: finger nuts - 120-200 Nm (12.0-20.0 kg/cm).

Replace the threaded bushings of the lower arms in the same way.

Lubricate the threaded joints with transmission oil through grease nipples.

Check the alignment of the front wheel angles. (GAZ-3110 wheel alignment)