Disassembly and assembly of the intermediate shaft of the GAZ-3110 gearbox

Press ball bearings 1 and, if necessary, pressed-on gear rings from the intermediate shaft

Assembling the intermediate shaft

Heat the gears to a temperature of 150 °C, cool the intermediate shaft for 30 minutes and press the gears onto the shaft.

Lubricate the cooled shaft and other parts with a thin layer of transmission oil.

Install the retaining ring.

Press the bearings onto the shaft, applying force to the inner rings of the bearings.

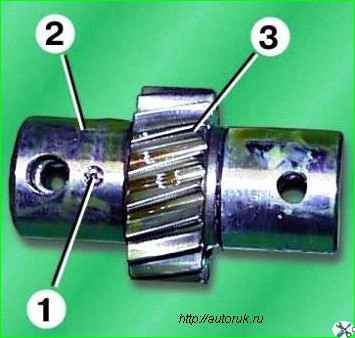

Disassembling the reverse idler gear axis

Press out spring pin 1 and remove bushing 2.

After this, you can remove the reverse intermediate gear 3 with the needle bearing.

Assembling the reverse idler gear axis

Lubricate the parts of the reverse idler gear axle with a thin layer of transmission oil.

Insert the bearing needles (21 pcs.) into the hole of the reverse intermediate gear.

For ease of installation, it is possible to lubricate the seat with grease.

Install the reverse idler gear onto the axle.

Install the bushing on the axle and turn it so that the chamfers for the axle mounting bolts in the bushing and head are in the same plane.

Press in the spring pin.