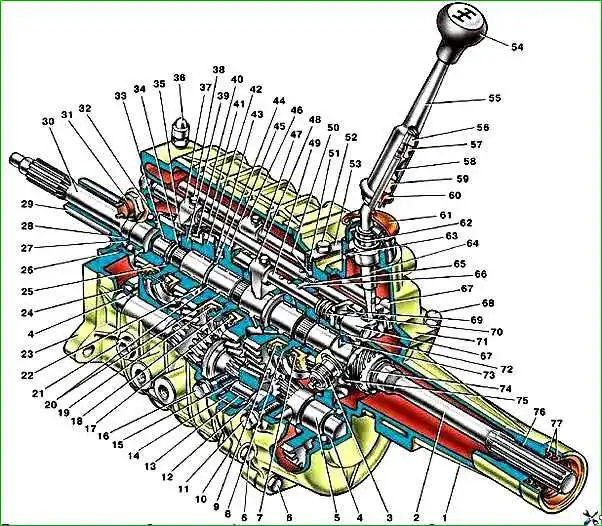

Five-speed transmission

The five-speed gearbox has a three-shaft design

The gearbox housing is made of aluminum alloy and consists of two parts - front 23 and rear 1.

To ensure alignment of the shaft supports and the holes for the shifting mechanism rods, the crankcases are centered using installation sleeves pressed into the front crankcase.

The front and rear crankcases are connected to each other by ten bolts 6.

For tightness between the crankcases, a paronite gasket 10 with a thickness of 0.33 mm is installed.

The input shaft gear 30, as well as the 1st, 2nd, 3rd, 5th and reverse gears are in constant mesh with the 5 gear block.

These gears are helical and rotate on 20 needle bearings with plastic cages.

The reverse intermediate gear 14 rotates on bulk rollers Ø 3 mm on axis 12, the supports of which are secured in both crankcases with bolts 11 and 16.

Forward and reverse gears are equipped with inertial synchronizers.

Axial movements of the parts of the secondary shaft 2 are limited by retaining rings 34 and 74, a thrust ring 72, two thrust half-rings 22 held by a retaining ring 43, and a shoulder of the secondary shaft.

The ball bearing of the input shaft is fixed on the shaft with retaining rings 27 and in the crankcase with 26.

The rear bearing 75 of the secondary shaft is also secured with a retaining ring.

The gear block 5 rotates on ball bearings 4 installed in the seats of the front and rear of the crankcases.

The axial clearance of the gear block is adjusted during assembly by selecting the thickness of the package of adjusting rings 24 installed in the seat of the front crankcase.

The rims of the gear block 5 are installed with tension on the intermediate shaft.

The locking device of the gear shift mechanism consists of two locking plungers 66 and a locking pin 65.

A locking sleeve with a spring is provided to prevent accidental engagement of reverse gear.

The gear shift rods are fixed by balls 50 loaded by springs 51.

The gear shift lever is equipped with a damping device that eliminates its vibration at high crankshaft speeds.

The tightness of the gearbox is ensured by three oil seals, one of which (item 28) is installed on the input shaft in the bearing cap of the input shaft 30, and the other two (item 77) are installed in the rear housing extension.

The oil drain plug is equipped with a magnet to catch metal wear products from the gearbox.