The frequency of changing the oil and filter element is 60 thousand km, but not less than every two years of vehicle operation

It is more convenient to perform the work on a lift.

Hang the front wheels and remove the battery.

Use a 10mm wrench to unscrew the nuts of the clamp securing the power steering reservoir.

Use a screwdriver to loosen the screws of the clamps securing the hoses to the tank.

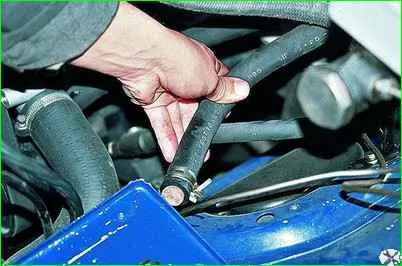

Having placed a container on the battery shelf and tilting the tank over it, remove the outlet hose (it has a larger diameter).

Drain the oil from the tank and remove the second hose.

To avoid spilling oil, we insert plugs into the hoses; these can be bolts of a suitable diameter, a bottle cap, etc.

To prevent the plugs from falling out, we clamp them with clamps.

Using an “8” socket wrench, unscrew the six bolts securing the engine mudguard and remove it

We take out the hoses removed from the tank from under the battery shelf and lower them down under the engine

Having removed the plugs, drain the oil from the hoses into a container installed under the car

Remove the power steering pump drive belt.

Rotating the pump pulley, vigorously turn the steering wheel several times from one extreme position to another.

We repeat the last two operations until oil stops flowing out of the hoses. To completely remove oil from the system, it is necessary to dismantle the pump and steering mechanism and drain the oil from each of them separately.

Assemble the hydraulic system in reverse order, installing a new tank with filter.

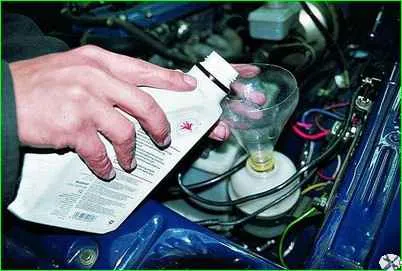

After filling the tank with fresh oil, pump the steering hydraulic system.

Bleeding the steering hydraulic system

We bleed the hydraulic steering system to remove any air that has entered there after changing the oil, filter, and other work related to the leakage of the system.

Signs of the presence of air: jamming of the steering wheel when the direction of its rotation suddenly changes, foam in the tank.

Hang the front wheels, add oil to the tank to the required level.

Turn the steering wheel 5-10 times to the extreme position in both directions.

If the oil has been drained from the system, then to speed up the filling of the hydraulic system, use a key set to “10” to unscrew the valve from the steering mechanism, turn the steering wheel 3-4 times in both directions, put the valve in place and add oil.

With the steering wheel in the middle position, we start the engine for 10-15 seconds. We do not rotate the steering wheel.

After turning off the engine, add oil.

Start the engine and, at idle, smoothly turn the steering wheel one at a time, in both directions, all the way, but without holding it in the extreme positions.

After the release of bubbles in the oil tank stops, stop the engine.

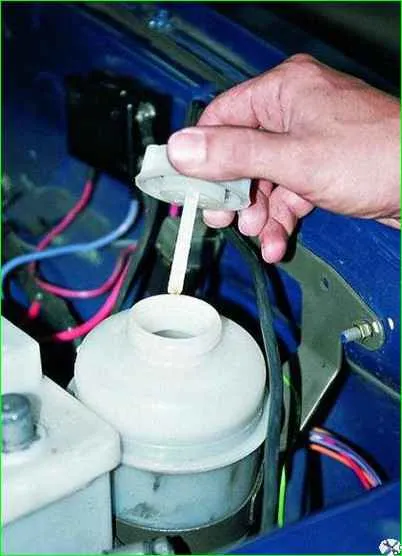

Add oil, checking its level on the dipstick.