Adjustment of the steering mechanism is necessary when the vehicle's directional stability is low at high speed

This defect is associated with a violation of the adjustment of the thrust bearings of the propeller, and in the rack-piston-shaft-sector pair of the steering mechanism.

After adjustment, the force required to rotate the input shaft should not increase noticeably.

During operation, you should constantly monitor the condition of the hoses, especially high pressure ones. If cracks, swelling or cuts occur, hoses must be replaced.

You should also check that there are no leaks of working fluid (oil) from under the hose clamps, steering gear covers or power pump.

When the pressure in the system increases due to jamming of the bypass valve, the technological plugs in the pump housing can be squeezed out, so you should monitor the system and the quality of the working fluid being filled, top it up, replace it and change the filter in a timely manner.

Do not hold the steering wheel in extreme positions for a long time. This can lead to damage and even jamming of the booster pump.

A slight noise when the amplifier is operating is not a sign of a malfunction.

Adjusting the thrust bearings of the steering screw

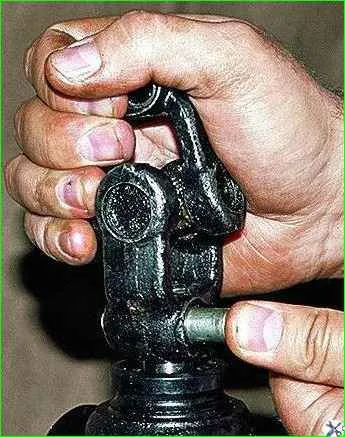

Having removed the steering mechanism along with the bipod, remove the universal joint fork from the input shaft of the steering mechanism.

We fix the steering mechanism in a vice with the input shaft up, positioning the screw axis vertically.

In the middle position of the sector shaft, with one hand we swing it by the bipod, and with the fingers of the other hand we check the absence of axial movement (play) of the input shaft of the steering mechanism.

If present, the propeller bearings must be adjusted.

To do this, use a bead to open (straighten) the collar of the adjusting nut.

Use a special wrench to turn the adjusting nut clockwise

Tighten the bearings.

Tighten the nut carefully, each time checking for axial play of the input shaft.

After your fingers stop feeling the movement of the shaft, stop tightening.

We lock the adjusting nut with a bead, bending its collar into the grooves of the crankcase

The force required to turn the input shaft after adjustment should not increase noticeably.

Adjusting the engagement of the piston-rack-shaft-sector pair

Remove the steering mechanism from the car along with the bipod (see Removing the mechanism with a GAZ-3110 power steering).

We install it in a vice in the same way as for adjusting the bearings.

If the steering screw bearings were adjusted before this operation, then place the universal joint on the steering shaft and insert the wedge.

Turn the steering shaft to the middle position of the bipod (a little less than two revolutions of the shaft from any extreme position).

In the middle position of the bipod, slightly turning the input shaft by the cardan, we determine the possible increase in the gap in the engagement of the piston-rack - shaft-sector.

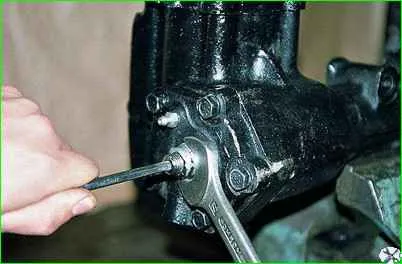

To adjust the engagement, unscrew the lock nut with a 22 wrench, while holding the adjusting screw with a 6 hex key.

Turn the adjusting screw counterclockwise and, at the same time turning the input shaft by the cardan joint at a small angle, control the engagement gap.

When the gap is no longer felt, tighten the locknut while simultaneously holding the adjusting screw from turning.