Engine injectors are removed for inspection or replacement

Preparing the car for the task.

Relieve the fuel pressure in the fuel system if the engine has just been stopped.

Disconnect the negative terminal from the battery

Remove the receiver as described in the article - Replacing the pressure reducing valve GAZ-3110

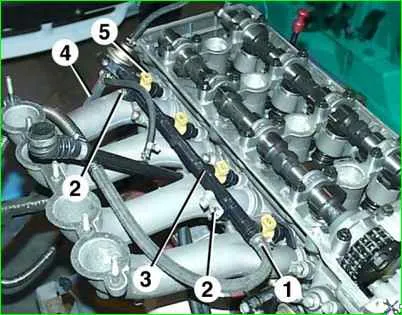

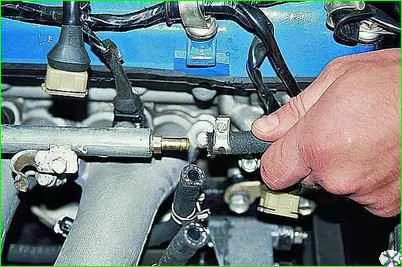

Then loosen the clamps and disconnect the fuel supply hose 1 from the engine fuel line 3.

Disconnect fuel drain hose 4 from the pressure reducing valve.

Disconnect the connectors with wires from connectors 5 of the four injectors.

Checking the injector without removing it from the engine

To check the serviceability of the injector, turn off the ignition and remove the negative terminal of the battery.

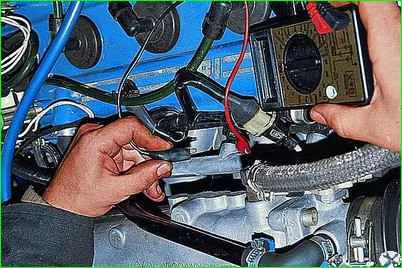

Use an awl or a thin screwdriver to snap off the spring clamp of the block

Disconnect the connector from the injector.

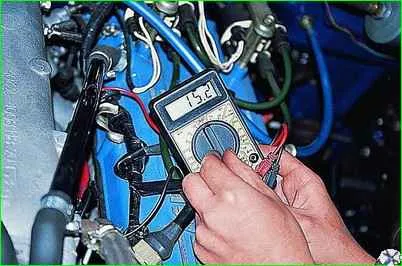

Connecting an ohmmeter to the injector terminals, measure the winding resistance

The winding of a working injector should have a resistance of 15–16 Ohms between the central and side pins of the connector

We carry out further tests on the injector removed from the engine.

Removing the injector

Relieve the fuel pressure in the power system.

Turn off the ignition and remove the negative terminal of the battery.

Disconnect the idle air control connector.

Remove the air supply duct and the air damper drive cable from the throttle pipe (see Replacing the GAZ-3110 pressure reducing valve).

Use a screwdriver to loosen the clamp of the lower (outlet) hose of the idle air regulator.

Use a screwdriver to loosen the clamp and remove the hose of the crankcase ventilation system.

Use a screwdriver to loosen the clamp and remove the brake booster hose.

Use a screwdriver to loosen the clamp and remove the fuel pressure regulator hose.

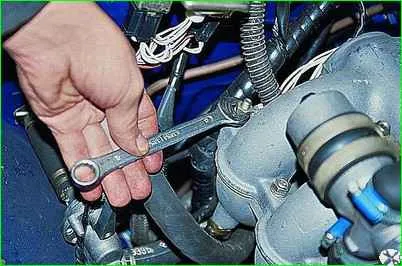

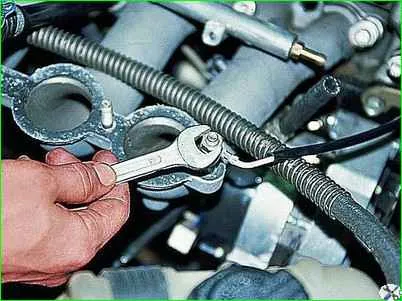

Using a 13mm wrench, unscrew the nut securing the tip of the ground wire to the first stud of the intake manifold.

In the same way, disconnect the wire from the last stud of the intake manifold.

Then, unscrewing the remaining nuts of the intake manifold studs with a 13mm wrench, remove the receiver

We loosen the clamp with a screwdriver

Remove the supply hose from the fuel rail fitting.

Use a screwdriver to loosen the clamp and remove the crankcase ventilation hose from the idle air system pipe.

Use a screwdriver to loosen the clamp and remove the drain hose from the fuel pressure regulator fitting.

Using a 10mm wrench, unscrew the two screws securing the fuel rail to the intake manifold and remove the rail

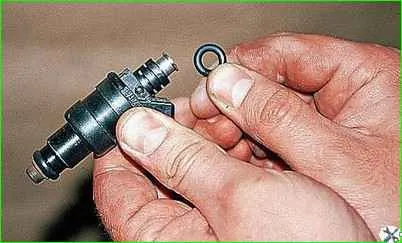

Pry the spring latch of the block with an awl and disconnect the connector from the injector

Remove the injector from the manifold

Installing the nozzle in reverse order

Checking the injector removed from the engine

When voltage is applied briefly from the battery, a distinct click should be heard.

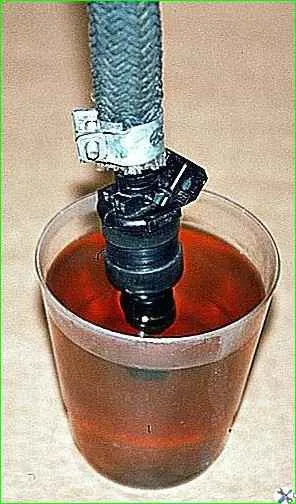

Remove the sealing collar from the nozzle flange and connect the nozzle with a rubber hose with a clamp to a source of compressed air (a compressor with a pressure gauge or a foot pump).

Having lowered the nozzle spray into kerosene, we supply air to it at a pressure of 3 kgf/cm 2.

For a working nozzle, air should not pass through the nozzle.

We check the quality of atomization of the fuel injector, for which:

We connect the ground wires that were removed from the intake manifold studs when removing the injectors.

By tightening the nuts with a 13mm wrench, we ensure reliable contact with ground

Place the fuel rail supply hose onto the injector flange and tighten the clamp with a screwdriver

Connect two wires at least 1 meter long to the injector terminals.

After making sure that the ignition is turned off, connect the negative terminal of the battery.

Turn on the ignition and, after waiting for the fuel pump to stop working, turn off the ignition.

Having secured the nozzle above the container, briefly connect the wires to the battery terminals.

Forsun it should produce a conical jet of finely atomized fuel.

If the nozzle does not work, change the polarity of the wires.

Relieve the pressure in the fuel line by applying voltage to the injector. Drain the gasoline into a suitable container

Replace the faulty injector.

Install all parts in reverse order.