The gearbox is removed for repair, as well as for repair of clutch parts

The gearbox weighs about 32 kg, so it is better to remove it with two people.

If there is no assistant, to be on the safe side, support the box with a hydraulic stop or a reliable stand.

Removing the gearbox

Install the car on an inspection ditch or lift.

Disconnect the wire from the negative terminal of the battery.

Drain the oil from the gearbox

Set the gearshift lever to neutral.

Use a screwdriver from inside the cabin and remove the front console insert.

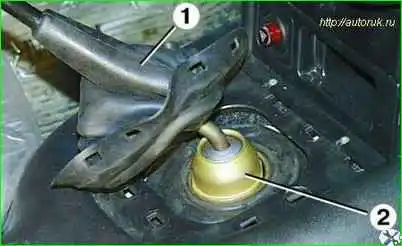

Push rubber boot 1 up.

Unscrew the cap 2 levers.

If the cap cannot be unscrewed by hand, you must use cobra pliers.

Pull up the gear shift lever assembly.

Take out the rubber floor seal.

Remove the driveline drive (see article - “GAZ-3110 driveline drive”

Disconnect the wires from the contacts of the reverse light switch.

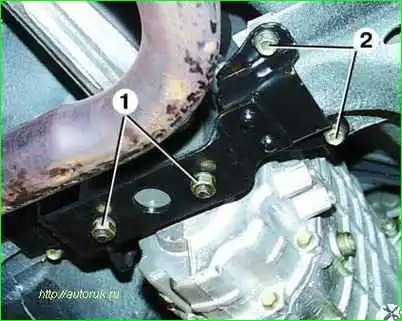

Disconnect block 1 with wires from the speed sensor and remove the wire from holder 2.

Unscrew the bolt and disconnect the exhaust pipe from the gearbox bracket.

Unscrew the two nuts 1 securing the rear support of the power unit to the gearbox.

Unscrew the four bolts 2 securing the rear power unit support bracket to the body.

Unscrew the two bolts securing the exhaust pipe flange to the muffler and disconnect the muffler and exhaust pipe.

Disconnect the muffler from the bracket securing it to the body.

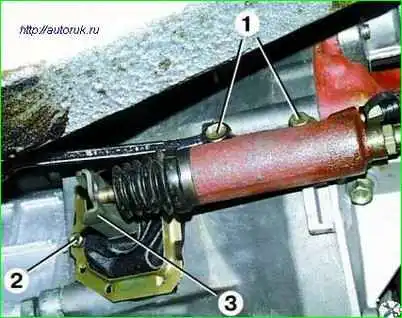

Unscrew the two bolts 1 securing the clutch slave cylinder to the clutch housing.

Unscrew bolt 2 securing the clutch fork cover frame and remove fork 3 together with the frame and cover.

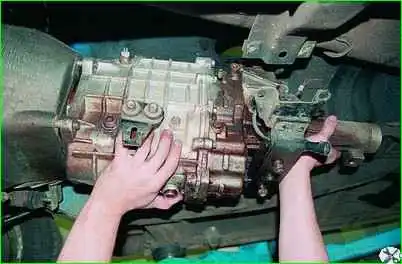

Unscrew the four nuts securing the gearbox to the clutch housing

Remove the gearbox, turning it clockwise. In this case, it is necessary to ensure that the input shaft does not damage the clutch parts.

If difficulties arise when removing the gearbox, it is necessary to completely remove the exhaust system

Installing the gearbox

It is recommended to install the gearbox with an assistant, since it is necessary to hold the heavy unit above your head and align the holes in the clutch disc and flywheel bearing with the input shaft, and the bearing cover with the hole in the clutch housing.

The installation sequence is the reverse of removal.

At the same time, tighten the nuts securing the gearbox to the clutch housing to a torque of 50–62 Nm (5.0–6.2 kgf m).