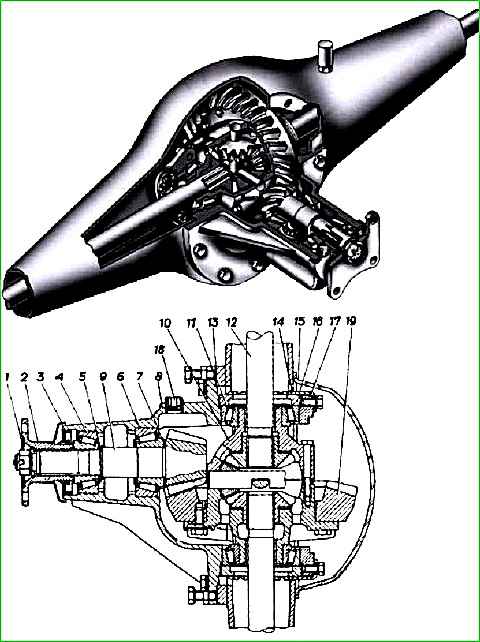

The vehicle is equipped with a rear axle with a stamped-welded banjo-type crankcase with a separately mounted gearbox

The main gear and rear axle differential are installed in the gearbox housing 8, which is bolted into the holes of the axle beam.

The main drive of the bridge is hypoid, with a gear ratio of 5.125; The axis of the drive gear relative to the driven gear is shifted downward by 42 mm.

The preload of the drive gear bearings is adjusted by selecting ring 5, and the position of the drive gear is adjusted by selecting ring 7.

The lateral clearance in the main gear engagement is adjusted with nuts 16.

The same nuts are used to adjust the preload of the differential bearings.

The nuts are locked using locking plate 14.

The satellites and side gears are located in the differential housing, consisting of left and right boxes fastened with bolts.

To prevent pressure build-up inside the bridge, a breather is installed on top of the left axle housing.

Possible malfunctions of the rear axle

- Cause of malfunction

Remedy

Noise (hum) of the bridge at high volume:

- Loosening the drive gear flange nut

Tighten the nut

- Wear or play of the working surfaces of the drive gear or differential bearings

Check the running surfaces of the bearings and, if necessary, replace them. Adjust bearing tension

Bridge pulsating noise (winding up)

- The driven gear fastening bolts are loose or it is installed askew

Tighten the driven gear mounting bolts and check the runout of its “back”

High pitch bridge "howl" noise:

- Insufficient or excessive oil level

Restore the oil level to normal

- Non-recommended oil is used

Change oil

- The contact between the teeth of the new final drive gears is incorrectly adjusted

Check the contact patch and adjust it

- Scoring on the working surface of the main gear teeth

Replace gears

Look at the article - "Removal, disassembly and assembly of the GAZ-2705 bridge"

A strong knocking sound in the axle when you sharply press the accelerator pedal after coasting or when cornering:

- Excessive wear of differential parts

Check the total play in the main gear and differential

Replace worn parts

Continuous knocking and crunching in the bridge:

- Wear of teeth or bearings

Replace worn parts

Oil leakage through the cuffs of the drive gear, hub, as well as along the plane of the crankcase and cover connector:

- Wear of drive gear cuffs and rear wheel hubs, drive gear flange, crankcase axle

Replace worn parts

- Breather clogged

Clean the breather

- Loosening the crankcase cover bolts

Tighten the bolts

- - Deformation of the crankcase cover

- - Damage to the cover gasket

Replace the cover

Replace gasket

Advice

Cars produced in 2007 and 2008 The rear axle stocking was produced with a defect; there were many cases of the stocking breaking in the area where the hub was attached.

Be careful when operating vehicles of this year. Do not overload the rear axle. There were cases of breakage along with the axle shaft.