The technical condition of the engine is constantly changing during operation

During the break-in period (about 2000 km), as the rubbing surfaces run in, friction losses decrease, engine power increases, fuel consumption decreases, oil waste decreases, then a period begins when the technical condition practically changes little

As parts wear out, gas breakthrough through the piston rings increases, compression in the cylinders decreases, oil leakage through the gaps in joints increases and pressure in the system drops.

Consequently, engine power gradually decreases, fuel consumption increases, and oil consumption increases.

Determining the technical condition of the engine for timely restoration repairs is very important.

This will extend the overall service life of the engine and prevent emergency engine failure.

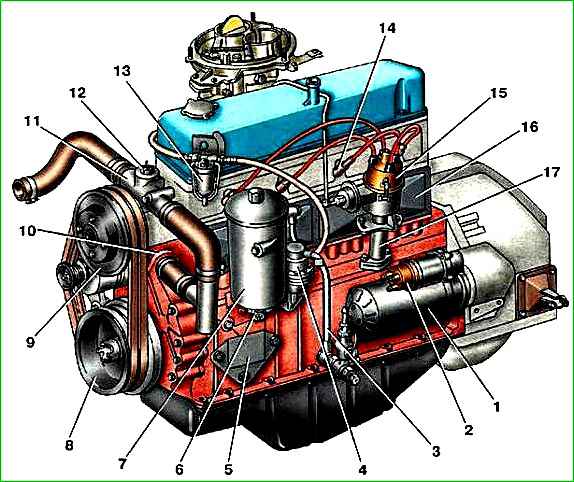

ZMZ-4025 and 4026 on the left side: 1 - starter; 2 - starter traction relay; 3 - oil line; 4 - fuel pump; 5 - engine support bracket; 6 - emergency oil pressure lamp sensor; 7 - oil filter; 8 - crankshaft pulley; 9 - water pump pulley; 10 - water pump; 11 - thermostat; 12 - coolant temperature indicator sensor; 13 - fine fuel filter; 14 - spark plug; 15 - ignition distributor; 16 - pusher cover; 17 - ignition distribution drive and oil pump

The condition of the engine is assessed by instrument indicators (coolant temperature and oil pressure), the nature of engine operation in various modes (uniformity, noise quality), the amount of compression in the engine cylinders, and the vehicle’s reaction to changes in fuel supply with the accelerator pedal.

A drop in engine power manifests itself in a decrease in the dynamic qualities of the car and a deterioration in throttle response.

The car accelerates sluggishly, has difficulty climbing hills (you have to downshift prematurely), and does not reach maximum speed.

It should be borne in mind that these symptoms may also be the result of a maladjustment of the vehicle’s chassis mechanisms.

The free rolling distance (run-down) of a serviceable vehicle, with a full load, moving at a speed of 50 km/h, must be at least 550 m.

This test is carried out in calm weather on a dry, horizontal section of the highway with asphalt or concrete pavement.

Fuel consumption (operational) depends not only on the technical condition of the engine, but also (if the vehicle's chassis is in good condition) on road conditions, load, and driving methods, therefore operational fuel consumption is not an objective indicator of the technical condition of the engine.

The technical condition of the engine (if other vehicle mechanisms are in good working order) is determined by the control fuel consumption when driving a fully loaded vehicle along a horizontal section of a highway with asphalt or concrete pavement at a speed of 60 km/h.

The test is carried out over a section of 4-5 km in two opposite directions.

The control consumption for a run-in car should not exceed 11 liters per 100 km.

When determining the control gasoline consumption, use a separate measuring tank.

The compression (pressure) in the cylinders at the end of the compression stroke is checked using a compression gauge.

Before measuring, you need to check the correctness of the thermal clearances in the valves and adjust if necessary.

Compression in the cylinders is measured with the engine warmed up to 70-85°C with the carburetor throttle fully open and the spark plugs turned out, the carburetor must be without fuel.

The rubber tip of the compression gauge is inserted into the hole of the spark plug of the first cylinder, providing a seal along the edge of the hole, and the engine crankshaft is cranked by the starter until the pressure in the cylinder stops increasing (but no more than 10-15 seconds).

The battery must be in good working order and fully charged.

Cylinder compression for the 4026 engine is less than 850 kPa (8.5 kgf/cm 2) and for the 4025 engine is less than 800 kPa (8 kgf/cm 2) indicates about wear or malfunction of the piston rings or leaking valve seating.

To establish the true cause of the malfunction, you should pour 20-30 cm of 3 engine oil through the spark plug hole into each cylinder and check the compression again.

An increase in compression indicates a malfunction (wear) of the rings or cylinder; if the compression value has not increased, then, therefore, the tightness of the valve seating is broken.

Oil consumption for waste is controlled by measuring the amount of oil, the proportion level indicator reached to the “P)) mark, for a certain mileage.

Gradually, as wear on engine parts increases, oil consumption increases.

If oil consumption due to waste exceeds 0.25 liters per 100 km, then the engine must be repaired.

The oil pressure in the system is checked with a control pressure gauge, which is attached to the oil filter instead of the oil pressure sensor (the thread in the filter is ¼ tapered).

Oil pressure is less than 100 kPa (1 kgf/cm 2) on a warm engine at average speed and less than 50 kPa (0.5 kgf/cm 2) at Low idle speed indicates a malfunction in the lubrication system or excessive wear of the crankshaft or camshaft bearings. This engine must be repaired.

The noise level of the engine is checked by listening to its operation at idle speed at different crankshaft speeds. the engine must be warmed up to a temperature of 70-85° C.

Without using a stethoscope, listen to the operation of the gas distribution mechanism: valves - at a rotation speed of 600-1200 min -1 pushers - at a rotation speed of 1000-1500 min -1 camshaft gears - at a rotation speed of 1000-2000 min -1.

Using a stethoscope, listen to the operation of the piston group, connecting rod and main bearings during a sharp short-term increase in the crankshaft speed to 2500 min -1.

Knocking and rattling of pistons, piston rings, knocking of connecting rod bearings, audible with a stethoscope, are not allowed; prominent knocking of piston pins, main bearings, knocking or sharp high-pitched noise of timing gears, sharp, prominent knocking of valves and pushers, sharp knocking and high-pitched noise of oil pump gears and its drive, high-pitched noise and squeaking of the impeller and bearing of the coolant pump, audible without a stethoscope.

Uniform knocking of valves and pushers is allowed, merging into general noise; periodic knocking of valves and pushers with normal clearances in the valve mechanism; prominent knocking of valves and pushers, disappearing or appearing with a sharp change in engine crankshaft speed; smooth, unsharp noise of the camshaft drive gears and the noise of the oil pump gears and its drive that does not stand out from the general background.

During the operation of the car, various engine malfunctions may appear, the elimination of which does not require taking the car to a special repair shop.

By the operation of the engine, with sufficient skill, you can judge its technical condition.

By hearing, increased gaps in joints, accidental breakdowns and loosening of fasteners can be detected.

If you discover any malfunction in the operation of the engine during operation, you should not rush to disassemble the engine, but try to determine the cause of the malfunction before disassembling.

They begin disassembling the engine after making sure that this operation is really necessary. Even partial disassembly of the engine, as a rule, disrupts the seals, the running-in of mating parts and increases their wear during subsequent operation.