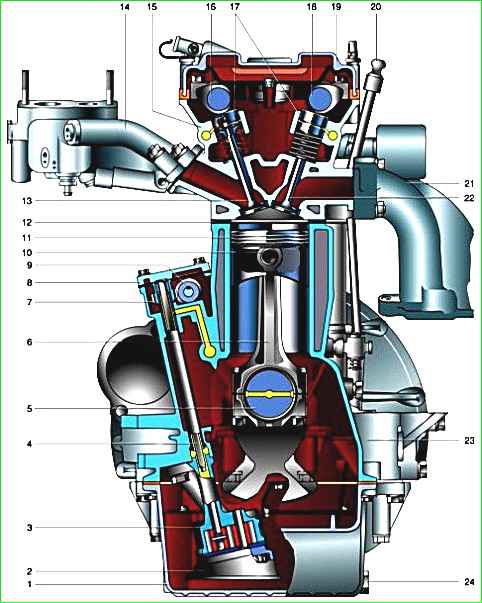

Engine ZMZ-4061 and 4063 carburetor, four-cylinder, in-line, four-stroke with four valves per cylinder and two camshafts in the cylinder head

Cylinder operating order: 1–3–4–2.

Cylinder block is cast iron, the cylinders are bored directly into the block.

There are ducts for coolant between the cylinders.

The coolant pump with fan and generator are driven by a poly-V belt located in the front of the engine.

The clutch housing is attached to the rear mating plane of the cylinder block.

ZMZ-406 engine: 1 - oil pan; 2 - oil intake; 3 - oil pump; 4 - oil pump drive shaft; 5 - crankshaft; 6 - connecting rod; 7, 9 - driven and driving gears; 8 - drive cover; 10 - piston pin; 11 - piston; 12 - cylinder head gasket; 13 - inlet valve; 14 - inlet pipeline; 15 - cylinder head; 16 - intake camshaft; 17 - hydraulic pushers; 18 - exhaust camshaft; 19 - cylinder head cover; 20 - oil dipstick; 21 - exhaust manifold; 22 - exhaust valve; 23 - cylinder block; 24 - oil drain plug

The power unit is attached to the car body on three supports - two rubber cushions are located on the right and left sides of the engine, the third support is installed under the rear gearbox housing.

The crankshaft is cast iron, rotates in five main plain bearings.

Axial movement of the shaft is limited by four thrust half-rings.

Connecting rods are steel, forged, I-section, the lower (split) head is connected to the crankshaft through connecting rod plain bearings, the upper head is connected to the piston pin.

Finger is a floating type, i.e. it rotates freely in the piston bosses and in the bronze bushing of the upper connecting rod head.

The axial movement of the piston pin is limited by two retaining rings installed in the grooves of the piston bosses.

Pistons - cast, made of aluminum alloy, with two compression rings and one oil scraper ring.

During operation, the pistons are cooled by a stream of oil through the holes in the upper heads of the connecting rods.

Cylinder head cast from aluminum alloy, with pressed-in cast iron seats and valve guides.

The valves are driven through cylindrical hydraulic pushers, so the valve drive does not need to adjust the clearances.

Camshafts are cast, cast iron, each rotates in five plain bearings.

They are kept from axial displacements by plastic half-rings installed in the grooves of the front covers and the grooves of the front bearing journals of the shafts.

The camshaft drive is a chain, two-stage (via an intermediate shaft sprocket).

The tension of both chains is provided by automatic hydraulic tensioners operating from the pressure in the lubrication system.

The engine lubrication system is combined: the main and connecting rod bearings of the crankshaft, piston pins, camshaft supports, bearings of the intermediate shaft and oil pump drive shaft, hydraulic tappets and helical gears are lubricated under pressure.

The remaining parts are lubricated by splashing.

Oil pump - gear, single-section, driven by an intermediate shaft via a pair of helical gears.

An oil cooler and a full-flow filter are built into the lubrication system.

The crankcase ventilation system is closed, forced, with crankcase gases removed through the oil separator into the intake system.

The engine is equipped with an exhaust gas recirculation system. It directs part of the exhaust gases into the intake manifold, thereby reducing toxicity.

Cooling system - liquid, closed type with forced circulation.

The coolant pump is a centrifugal type, driven from the crankshaft by a poly-V belt together with a fan. The cooling system has a built-in thermostat.