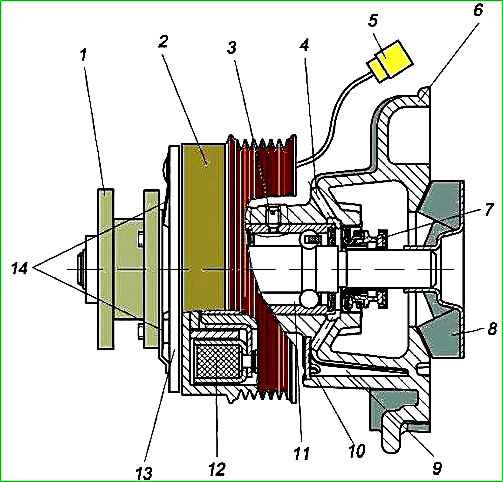

The water pump is a centrifugal type, with an electromagnetic clutch for the fan drive, installed on the chain cover, the pump supplies coolant to the cylinder block

The tightness of the pump is ensured by a self-clamping mechanical seal 7, which is pressed into the housing 6 of the water pump and onto the bearing shaft 11.

The coolant penetrating through the seal does not enter the bearing, but flows through the hole into the drainage cavity 9, closed with a plug.

The liquid that accumulates in the drainage cavity during engine operation gradually evaporates through holes 10 and 4.

The steam penetrating through the seal evaporates into the atmosphere through hole 4.

During operation, it is necessary to monitor the cleanliness of holes 4 and 10, and, in order to prevent premature failure of the bearing, when carrying out maintenance-2 holes must be cleared of contamination.

The presence of constant leakage from the control hole 10 of the drainage cavity indicates a loss of seal tightness and the need to replace the water pump.

Bearing 11 is kept from moving in the water pump housing by clamp 3, which is screwed in until it stops and is cored.

The bearing with two protective seals is filled with lubricant at the manufacturer and does not require adding lubricant during operation.

A stamped steel impeller 8 is pressed onto the bearing shaft.

At the front end of the water pump housing, the electromagnet coil 12 of the electromagnetic clutch is fixedly mounted on a holder.

Fan mounting hub 1 is mounted on the water pump bearing shaft on a ball bearing.

In the absence of voltage on the electromagnet, hub 1, together with driven disk 13, is disconnected from pulley 2 and rotates freely at a low angular velocity.

When voltage is applied to the clutch electromagnet, the driven disk 13, overcoming the force of the leaf springs 14, is attracted to the pulley 2 and the fan hub begins to rotate together with the pulley and the water pump bearing roller.

When the voltage is removed from the clutch electromagnet, leaf springs 14 move disk 13 away from pulley 2, separating the hub and pulley.

The electromagnetic clutch is connected to the vehicle's electrical system using connector 5.

Voltage is supplied to the clutch electromagnet according to a signal from the control unit via a relay when the coolant temperature rises above plus 93:1: 2 °C, switching off when it drops below plus 91:1: 2 °C.

Main parameters of the electromagnetic clutch:

Supply voltage—10.8-15V.

Electrical power consumption - no more than 50 W.

Transmitted torque at a voltage of 12 V is at least 20 Nm (2 kgf m).

Minimum response voltage is 10 V.

Transmitted torque at minimum voltage is not less than 11 Nm (1.1 kgf m).

The gap between the driven disk and the pulley is 0.2-0.5 mm.

A water pump with an electromagnetic clutch is a non-repairable product. If the water pump or electromagnetic clutch fails, the entire assembly must be replaced.

The water pump and generator (without power steering pump) are driven by a 6RK 1275 poly V-belt from the crankshaft pulley.

The gear ratio of the water pump drive is 1.11.

The belt tension is carried out by an automatic tensioning device, which provides the necessary tension of the belt when it is stretched and damping (damping) vibrations occurring in the drive.

During operation, the tensioner does not require maintenance or adjustment.

In addition to eliminating the need to adjust the belt tension, the use of an automatic tensioner allows you to increase the service life of the accessory drive belt and the service life of the bearings of the water pump, generator and tensioner roller.

Replacing the ZMZ-40524 engine coolant pump

Draining the liquid from the cooling system, see the article - Replacing the coolant in a GAZelle car

For a better approach, remove the radiator, see the article - Removing and installing the radiator of a GAZelle car

Loosen the clamp securing the radiator outlet hose

Remove the outlet hose from the water pump nozzle

Loosen the clamp securing the hose to the thermostat

Loosen the clamp securing the coolant intake tube hose

And remove the hoses from the water pump pipes.

Remove the drive belt for auxiliary units, see the article - Replacing the drive belt for GAZelle vehicle units

Remove the bolt securing the water pump housing

Unscrew the top nut

Turn out the bottom bolt

Unscrew the lower nut securing the water pump

Remove the pump mounting bolt from the exhaust manifold side

Remove the water pump assembly with the electromagnetic clutch of the radiator fan drive of the engine cooling system

Remove the gasket and clean the surface of gasket residues

The water pump is sold together with an electromagnetic clutch

Install the parts in reverse order.

Before installing the pump, you need to apply sealant to the mating surfaces. Fill in coolant.

Checking the electromagnetic clutch of the water pump

Check the rotation of the fan mounting hub. The hub must rotate freely.

If the driven disk touches the end of the pulley, the hub bearing is stuck, or there is large play in the hub bearing, replace the water pump assembly with the clutch.

To check the maximum transmitted torque by the clutch, secure the water pump to the pulley and, using a torque wrench, set the moment at which the hub rotates relative to the pulley when 10 V and 12 V are applied to the clutch.

The moment must be at least 1.1 kgf and 2.0 kgf, respectively.