Insufficient belt tension impairs airflow to the radiator of the cooling system and leads to engine overheating and increased belt wear.

If the belt tension is too high, the fan drive and tension roller bearings may fail.

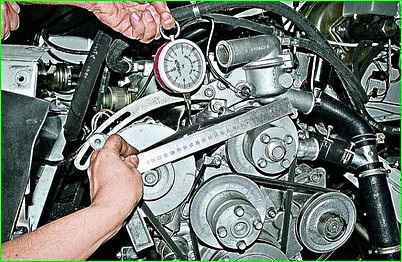

With correctly adjusted tension, the belt should bend by 8–10 mm when a force of 40 N (4.0 kgf) is applied in the middle between the fan pulley and the tension roller.

Belt tension is adjusted by moving the tension roller.

Replacing and adjusting the tension of drive belts for units with a ZMZ-402 engine

We recommend replacing both accessory drive belts if at least one of them fails.

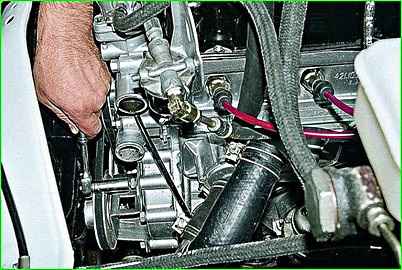

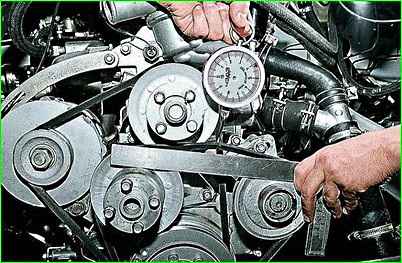

1. Using a 13mm socket, loosen the nut of the upper fastening of the tension pulley bracket (the cooling system hoses have been removed for clarity).

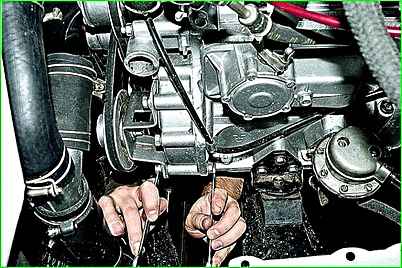

2. Use a 14 wrench to loosen the lower fastening of the tension pulley bracket, holding the bolt with a 12 wrench

3. We bring the tension pulley bracket to the block and remove the belt from the pulleys

4. After passing the belt between the fan impeller and the radiator, remove it

Loosen the upper and lower fastenings of the generator

We bring the generator to the cylinder block.

Remove the belt from the pulleys, threading it through the fan impeller, similar to removing the fan drive belt.

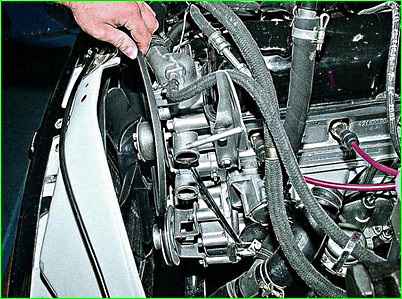

We put new belts on the pulleys.

Tension the fan drive belt, moving the tension pulley away from the cylinder block, and tighten the upper and lower fastenings of the tension pulley.

Tighten the generator drive belt in the same way, moving the generator away from the cylinder block, after which we tighten the upper and lower fastenings of the generator.

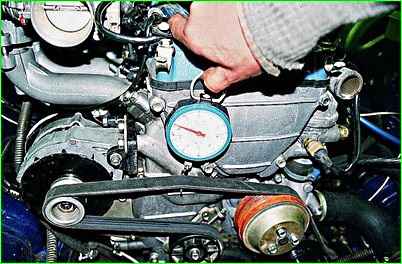

Check the belt tension adjustment by applying a force of 4 kgf to the middle of the upper branches.

The deflection of the generator drive belt should be 8–10 mm, and the fan drive belt should be 7–9 mm.

If necessary, repeat the adjustment.

Replacing and adjusting the tension of the drive belt of units with the ZMZ-406 engine

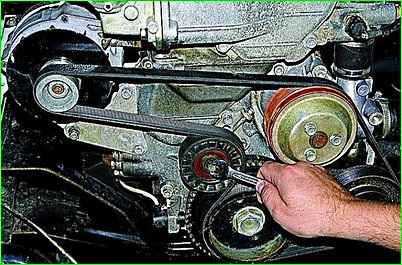

Using a 12mm wrench, loosen the bolt securing the tension roller (for clarity, the engine radiator has been removed).

Relax the belt tension by turning the tension roller bolt counterclockwise with a 10-degree wrench

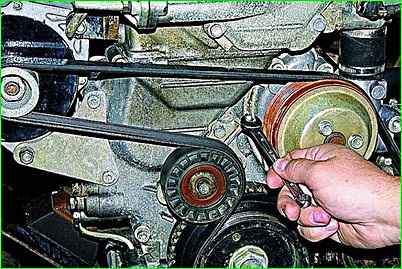

Remove the belt from the pulleys.

Installing a new belt.

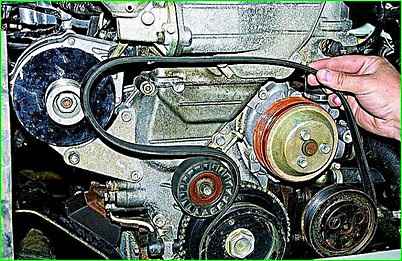

By rotating the tension roller bolt, we achieve a belt deflection of 15 mm under a load of 8 kgf applied in the middle of the horizontal drive branch (between the generator and pump pulleys)

Tighten the tension roller bolt.