Preparing the car for the task

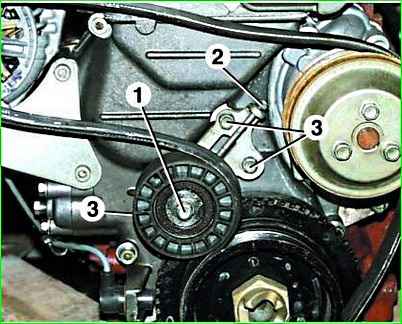

Loosen bolt 1 by two to three turns.

Unscrew the adjusting bolt 2, loosen the belt tension and remove it.

Inspect the belt.

If there are cracks, rubber delamination, tears, dirt deposits between the ribs, etc., replace the belt. Inspect the pulleys.

If there is dirt or damage, clean or replace the pulleys.

If you need to remove the tensioning device, unscrew the three bolts 3, and to make it easier to unscrew the bolt under the roller, move the roller up.

Details:

Replacing and adjusting the tension of the accessory drive belt

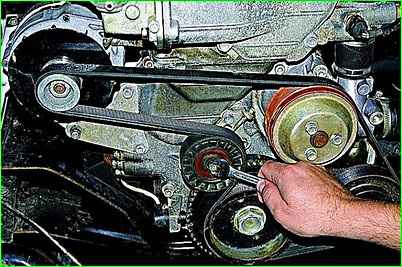

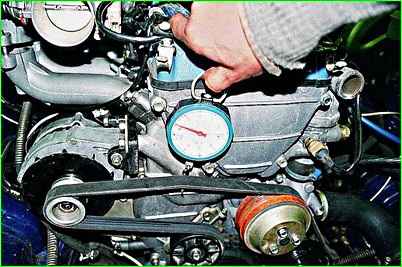

Using a 12mm wrench, loosen the bolt securing the tension roller (for clarity, the engine radiator has been removed).

Relax the belt tension by turning the tension roller bolt counterclockwise with a 10-degree wrench

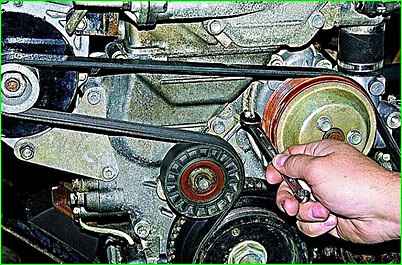

Remove the belt from the pulleys

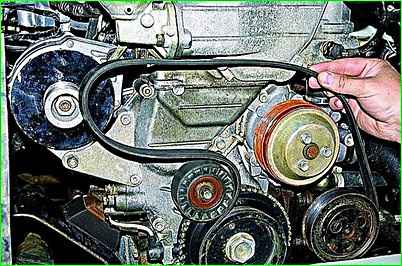

Installing a new belt.

By rotating the tension roller bolt, we achieve a belt deflection of 15 mm under a load of 8 kgf applied in the middle of the horizontal drive branch (between the generator and pump pulleys).

Tighten the tension roller bolt.

Replacing the tension pulley and accessory drive belt tensioning mechanism

Relax the tension of the drive belt.

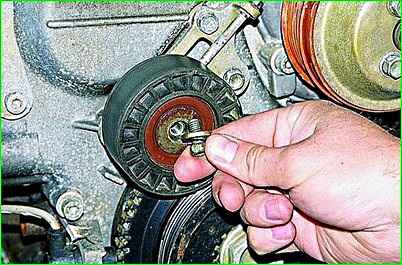

Completely unscrew the tension pulley mounting bolt

Remove the pulley from the tensioner axis.

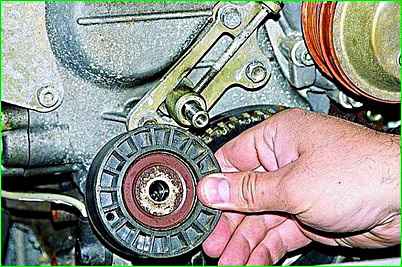

If necessary, use a socket wrench or a 12mm socket to unscrew the three tensioner mounting bolts

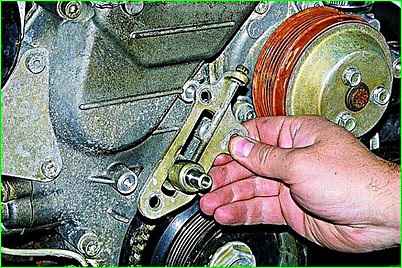

Remove the tensioner mount from the engine

Install the tensioner and pulley on the engine in the reverse order, and then tighten the belt.