In this article we will look at the exhaust gas recirculation system, the exhaust system and the engine mount

The remaining systems of the ZMZ-402 engine are discussed in the following articles:

- - Engine cooling system - Engine cooling ZMZ-402 GAZ-2705

- - engine lubrication system - Oil system ZMZ-402 GAZ-2705

- - ignition system - Ignition system engine 402 GAZ-2705

- - gas distribution mechanism - Gas distribution mechanism ZMZ-402 GAZ-2705

- - engine power system - ZMZ-402 power system features

Crankcase ventilation system - closed forced operating due to vacuum in the intake pipe and air filter

When the engine is running, gases are sucked out of the crankcase: at idle and at low loads - through a calibrated hole in the carburetor into the intake pipe; at full load - through an air filter; in other modes - through an air filter and a calibrated hole in the carburetor

With the engine running and the ventilation system working properly, there should be a vacuum in the crankcase, which can be determined using a water piezometer connected to the oil level indicator pipe.

If the system is not working properly, there will be excess pressure in the crankcase.

This is possible in case of coking of the ventilation channels or excessive breakthrough of gases into the engine crankcase.

When operating the vehicle, do not break the tightness of the engine crankcase ventilation system and do not allow it to operate with the oil filler neck open: this causes increased engine wear.

Engine recirculation system

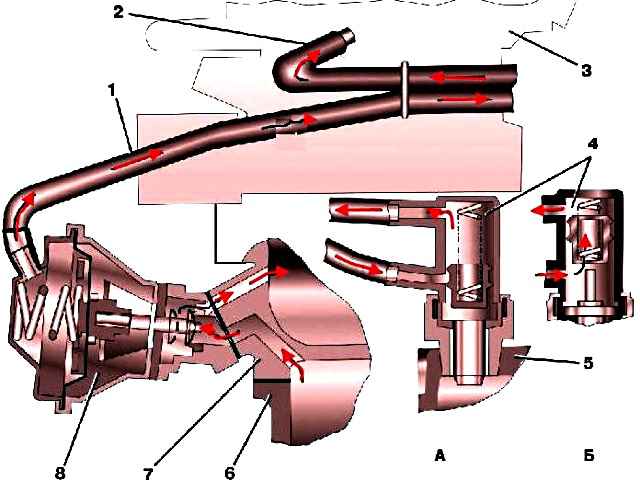

Some cars are equipped with an exhaust gas recirculation system, which consists of a recirculation valve 8 installed on the gas pipeline, a thermal vacuum switch 4 screwed into the water jacket of the cylinder head, and two connecting hoses.

Recirculation of exhaust gases into the intake tract is carried out with the engine warmed up to a coolant temperature of at least 35-40 ° C, at partial loads.

The exhaust gas recirculation system does not operate at idle or when the throttle valves are fully open.

To check the functionality of the exhaust gas recirculation system, it is necessary, on a warm engine, to increase the crankshaft rotation speed at idle from low speed to 3000 min -1 no more, and visually observe the movement of the valve stem 8.

If the rod does not move, check for the presence of control vacuum on the diaphragm mechanism of the recirculation valve.

If there is a vacuum, then the valve is faulty and needs to be replaced.

If there is no control vacuum, the thermal vacuum switch must be replaced.

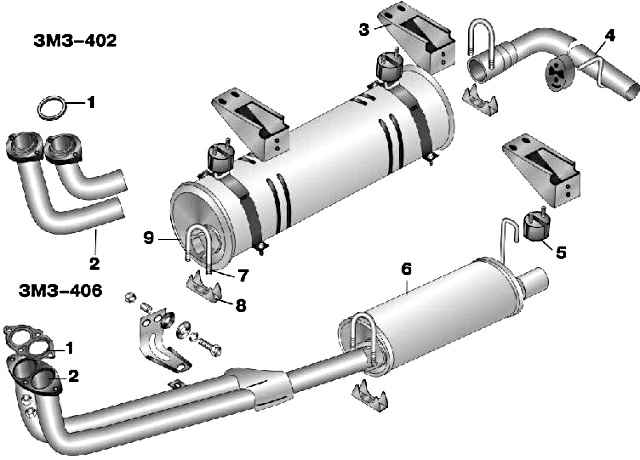

The exhaust system consists of the engine exhaust manifold, exhaust pipes connected by a gas receiver, a resonator, a muffler and an exhaust pipe.

The muffler and resonator are of a non-separable design and are attached to the frame using brackets and rubber shock absorbers.

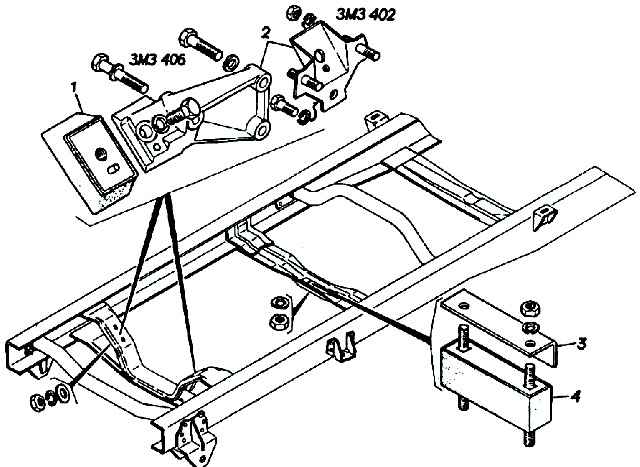

Engine mount consists of two engine mounts, two rubber mounts located on either side at the front of the engine, and a rear rubber mount under the transmission extension.

Rubber pads are installed on the frame cross members.