To check and remove the idle air control (IAC), you need to remove the throttle assembly completely (see “Removing the throttle assembly”) or partially

During partial dismantling, we disconnect the throttle valve drive cable, crankcase ventilation hoses and the canister purge solenoid valve from the throttle assembly.

After unscrewing the two nuts securing the throttle assembly to the receiver, remove the assembly from the studs without disconnecting the coolant hoses from it.

With the ignition off, release the latch and disconnect the engine control system wiring harness block from the IAC.

The regulator connector terminals are marked with the letters “A”, “B”, “C” and “D” on the block body.

To check the regulator supply voltage, turn on the ignition.

Using a tester, we measure the voltage between terminal “A” of the wiring harness block and ground.

We carry out the same measurements for other terminals of the wire block.

In each case, when continuously measuring voltage, the tester readings should vary in the range from 0.5 V to 12.0 V.

To check the serviceability of the regulator itself, use a tester (in ohmmeter mode) to measure the resistance between the terminals of the regulator connector.

In a working regulator, the resistance between terminals “A” and “B”, as well as “C” and “D” should be 40 - 80 Ohms.

To remove the idle speed regulator, use a Phillips screwdriver to unscrew the two screws securing the regulator to the throttle assembly (for clarity, shown on the removed throttle assembly).

Remove the idle speed control

The connection between the regulator and the throttle assembly is sealed with a rubber ring.

Install the idle speed control in reverse order.

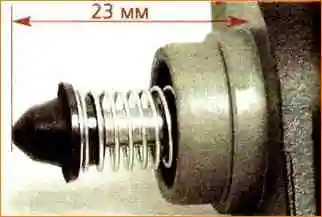

Before installing a new regulator, use a caliper to check the distance between the end of the valve needle and the supporting surface of the regulator flange.

The distance should be no more than 23 mm. This is necessary in order not to damage the regulator during installation.

The regulator needle should not rest against the throttle seat.

If the distance is more than 23 mm, then you need to use a special regulator tester to pull the locking needle inside the regulator.

Before installing the regulator, clean the valve seat, air channel and surface for the regulator sealing ring in the throttle assembly.

Apply engine oil to the sealing ring of the regulator. The tightening torque for the regulator mounting screws is 3 – 4 Nm.