The pneumatic brake system of a bus consists of a compressor, pneumatic devices and pipelines

In order to prevent failures of the pneumatic devices of the brake system from clogging, a strainer for purifying compressed air is installed at the inlet of the brake valve, dryer, four-circuit safety valve and in the modulators (2 each).

The first check of the condition of the filters should be carried out after the bus has been run in.

If the mesh is clogged, it is necessary to unscrew the filter from the fitting of the pneumatic device body using pliers and clean it with compressed air.

Further checks of the filter condition are recommended during seasonal maintenance.

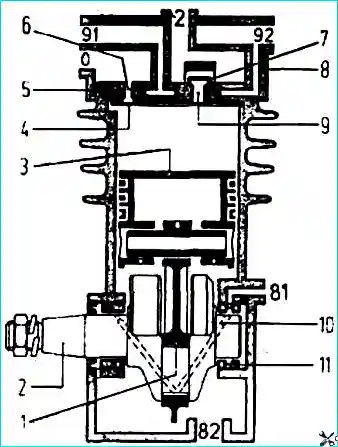

Compressor - (Fig. 1) single-cylinder piston type, with air-cooled cylinder block and water-cooled cylinder head.

The compressor is driven by a belt from the crankshaft pulley. Belt tension is adjusted by moving the compressor bracket.

Oil to the connecting rod journal is supplied to the bore of the compressor crankshaft through the rear cover through a hose from the engine lubrication system.

Ball bearings, piston pins and cylinder walls are splash lubricated. The oil is drained from the compressor into the engine oil sump.

When servicing the compressor, the fastening of the compressor to the bracket, fastening of the bracket to the engine, fastening of the pulley, tension of the drive belt, fastening of the compressor cylinder head, as well as the condition and fastening of the compressor discharge hose and coolant supply hoses to the engine are checked. cylinder head.

Tightening the cylinder head nuts should be done evenly diagonally in several steps, each step no more than 1-2 edges.

Final tightening is performed with a torque of 18-25 Nm (1.8-2.5 kgf m).

When installing a new compressor, after a 15-minute run-in, you should check the tension of the drive belts.

For a compressor manufactured by AK ADVIS OJSC, it is recommended to clean the pistons and valves from carbon deposits once a year during seasonal maintenance, but not more than after 100,000 km.

Signs of a compressor malfunction are: the appearance of noise and knocking in it, excessive heating (more than 190˚C), increased oil content in the condensate drained from the air cylinders.

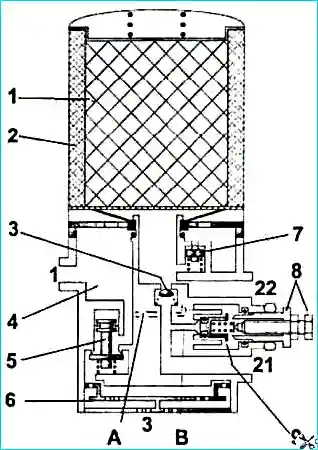

Inlets: 1 - inlet from the compressor; 21 - outlet to the four-circuit safety valve; 22 - outlet to the regeneration air receiver; 3 - atmospheric output

An air dryer with a built-in pressure regulator (Fig. 2) is designed to clean compressed air from moisture and contaminants, as well as to automatically maintain operating pressure in the pneumatic brake drive system.

The air supplied by the air compressor passes through the ring filter 2, where it is pre-cleaned from contaminants.

The air is cooled there, and part of the moisture contained in it is collected in moisture separation chamber 4.

The air is then dried, passing through granular powder 1, and enters the check valve 3, opens it and passes through outlet 21 to the four-circuit safety valve and then to the air receivers.

At the same time, an air receiver with a capacity of 5 liters is filled through the nozzle and outlet 22 to regenerate the drying element.

Attention! The air dryer has an electrically heated valve assembly, which is activated by a button on the instrument panel.

Electric heating turns on automatically at an ambient temperature of less than +10°C and turns off after heating to +30°C.

The dryer does not require special maintenance.

To monitor the normal operation of the dryer, you should check daily for the absence of condensation in the cylinder located after the dryer and monitor the tightness of the pneumatic drive of the brake system.

If used correctly, the dryer filter element provides high-quality air purification for two years.

If condensation appears in the receivers, the filter must be replaced cozy element.

If there is oil in the condensate, it is necessary to repair the compressor, since oiling the desiccant powder granules sharply reduces its service life.

Replacing the air dryer filter element is carried out in the following order:

- 1. Clean the surface of the dryer from dirt.

- 2. Loosen the threaded connection of the discharge pipe from the compressor and bleed air from it.

- 3. Unscrew the filter element cartridge by rotating counterclockwise.

- 4. Install a new cartridge, lightly lubricating the sealing gasket with oil.

- 5. Tighten the cartridge by hand to a torque of no more than 15 Nm (1.5 kgf m).

- 6. Tighten the threaded connection of the discharge pipe.

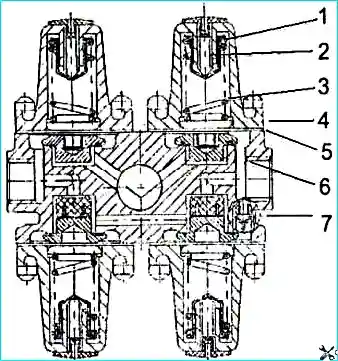

Four-circuit safety valve is designed to divide the supply line into two main and two additional circuits, automatically turn off one of the circuits in case of damage and preserve the supply of compressed air in undamaged circuits, as well as to preserve air during all circuits in case of damage to the supply line.

The safety valve sections are adjusted in such a way that first the main valves of the service brake system and the door drive open (in Fig. 4, sections 21, 22, 24) at a bypass pressure of 6.2 +0.3 kgf/cm 2, and then the parking brake system valve (section 23) opens at a bypass pressure of 6.7 +0.3 kgf/cm 2.

When section 21 is depressurized into it from section 23 through a specially built-in valve, compressed air is bypassed at a rate of at least 60 l/min.

After the bypass, the residual air pressure in the energy accumulators should be no more than 1 kgf/cm 2 .

Adjusting the valve eliminates the possibility of starting the bus when filling the pneumatic system with compressed air to the point that ensures braking of the bus with the required efficiency, and also eliminates the possibility of releasing the parking brake system of the bus when the pressure level in circuit 1 of the service brake system drops below a minimum level of less than 4.0 kgf/cm 2.

The parking brake manual valve is designed to control the spring energy accumulators of the parking brake system.

When the bus is moving, the crane handle is in the extreme forward position. The crane device ensures that the handle automatically returns to the lower position when it is released.

The handle is fixed only in the rearmost position.

To release spring energy accumulators, the handle should be pulled out in the radial direction, while the handle freely returns to the “released” position.

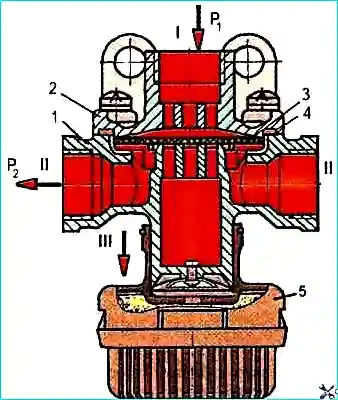

Quick release valve is designed to speed up the release of air from the actuators, by reducing the path traveled by compressed air during release.

The valve is installed near the brake chambers of the rear axle.

When the parking brake valve handle is in the “released” position, compressed air enters outlet “I” of the valve (Fig. 5), diaphragm 3 is pressed against the outlet seat in the housing; in this case, the edges of the diaphragm are bent and compressed air passes into terminals “II” and further into the energy accumulators.

When the pressure in terminal I drops, diaphragm 3, under the action of compressed air in terminals II, is torn away from the outlet seat in housing 1 and pressed against the seat in cover 2, thereby blocking the passage of air into terminal “I”. Compressed air is released into the atmosphere through terminal "III".

Possible malfunctions of the quick release valve include: leakage of compressed air through the connector of cover 2 (Fig. 5) and housing 1, which occurs due to loosening of the cover or a defect in the sealing ring 4, and the release of compressed air into the environment from terminal “III” due to a malfunction of the membrane 3.

To disassemble the quick release valve, you need to unscrew the four screws securing cover 2.

When replacing membrane 3, rubber O-ring 4 must also be replaced at the same time.

After assembling the valve, it must be installed on a stand and tested for operability and tightness according to the diagram shown in the figure (close the right terminal “II” with a plug), according to the following method.

Apply and release air at a pressure of 0.75 MPa three times to terminal “I”.

- set the pressure in terminal “I” to 0.02 MPa. In this case, pressure should appear in pin “II.”

- Increase the pressure in terminal “I” to 0.75 MPa. In this case, the pressure in terminal “II” should increase.

The difference between the pressures in terminals “I” and “II” should not exceed 0.02 MPa.

The valve must be checked for leaks under a pressure of 0.5 MPa at port “I”. When washing, the appearance of air bubbles is not allowed for 1 minute.

Next, you need to set the pressure to 0.75 MPa in terminals “I” and “II” and successively reduce the pressure in terminal “I”.

In this case, a corresponding decrease in pressure should be observed in terminal “II”, and air should escape from the atmospheric terminal “III”.

When the pressure in terminal “I” decreases to zero, the pressure in terminal “II” should become zero.

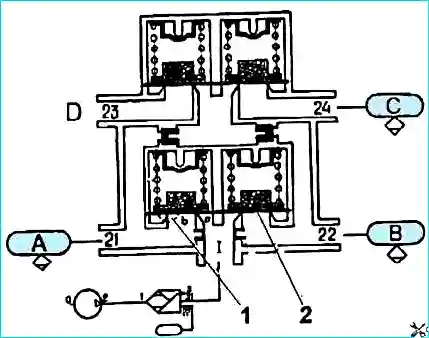

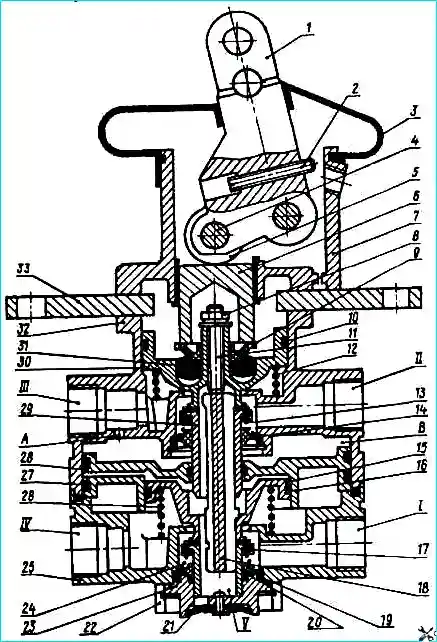

The brake valveth (Fig. 6.) is designed to control wheel brake mechanisms with a dual-circuit brake drive.

Terminals “I” and “II” (see Fig. 6) of the valve are connected to the air receivers of two separate service brake drive circuits.

From terminals “III” and “IV”, compressed air flows to the brake chambers. Brake signal switches are installed in the crane body.

When servicing a brake valve the valve’s fastening to the body base bracket is checked, the integrity of the protective rubber boot and the tightness of its installation are checked, and a diagnostic check is made for the correct operation of the valve.

In winter, if the tap freezes, to prevent damage to rubber and plastic parts, it is not recommended to warm the tap with an open fire.

You should use warm air or hot water for heating.

Due to the gradual disruption of the mobility of the brake valve pistons during bus operation, especially when water and oil get inside the valve on the friction surface, it is recommended to carry out a diagnostic check of the operation of the valve during TO-2. To do this, without removing the valve from the bus, you need to connect one pressure gauge to its upper and lower sectional terminals and, pressing the brake pedal, note the pressure difference. The pressure difference should not exceed 0.25 kgf/cm 2.

If this condition is not met, the crane must be repaired.

It is recommended to carry out preventive disassembly of the brake valve once every 2 years to clean, lubricate and replace rubber O-rings and worn parts.

Assembling and checking the functionality of the brake valve

1. Assembly should be carried out taking into account the following requirements:

- a) assembly must be carried out under conditions that exclude the possibility of abrasive dust, etc., coming into contact with the assembled parts.

- b) assembly of rubber parts must be done carefully to prevent the possibility of damage. The presence of cuts, scratches and other defects on rubber parts is not allowed.

- c) lubricate all rubbing surfaces of parts with a thin layer of lubricant CIATIM 221. Can be used with smear ZhT-72 TU 38.101.345-77 or ZhT 79L TU 32CT 1176-86.

- 2. Before installing the upper piston, measure the distance “c” (Fig. 8) of the protrusion of the piston shank above the valve.

- 3. Using the adjusting screw in the upper piston, set the distance a = (c + 0.8) mm and lock the adjusting screw.

- 4. Install the upper piston and, if necessary, press it with a transport clamp.

- 5. Assemble the apparatus with the base plate and lever.

- 6. Install the adjusting bolt all the way into the lever so that there is no gap between roller 4 and pusher 5 (Fig. 7), fix adjusting bolt 2.

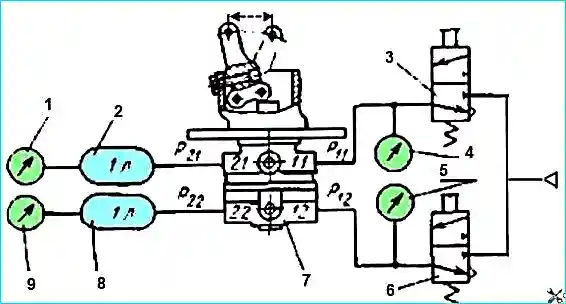

- 7. Connect the tap to the compressed air system in accordance with the test diagram (Fig. 7).

- 8. Move the lever three times until it stops (travel of at least 31.2 mm). When moving the lever there should be no jamming and it should quickly return to its original position.

- 9. Supply air under pressure P11 = P12 = 0.75 mPa (7.5 kgf/cm 2) to terminals 11 and 12. Move the lever all the way and back three times. The pressure in terminals 21 and 22 should change from 0 to the pressure in terminals 11 and 12 and back.

- 10. When the lever moves 4.7-7.4 mm (pusher stroke 1.9-3.0 mm), pressure should appear in terminal 21. When the pressure in outlet 21 reaches P21 = 0.05 mPa (0.5 kgf/cm 2), the pressure in outlet 22 must be at least 0.025 mPa (0.25 kgf/cm 2).

In this case, the lever stroke must exceed 4.7 mm (the pusher stroke must exceed 1.9 mm).

The increase in pressure in terminal 21 ahead of the increase in pressure in terminal 22 can be maintained over the entire pressure range, but not exceed 0.025 mPa (0.25 kgf/cm 2).

The initial pressure surge in terminals 21 and 22 should not exceed 0.02 mPa (0.2 kgf/cm 2).

- 11. When the pressure P21 = 0.3 mPa (3.0 kgf/cm 2) is reached in terminal 21, the lever stroke should be 14.5-19.9 mm (stroke pusher 5.8-8.0 mm).

- 12. When pressure P21 = 0.75 mPa (7.5 kgf/cm 2) is reached in terminal 21, the lever stroke should be 21-27 mm (pusher stroke 8.4- 10.8 mm).

- 13. The total stroke of the lever to the stop should be 31.1-39.1 mm (pusher stroke 12.5...15.7 mm).

- 14. When the lever moves smoothly, the pressure in terminals 21 and 22 after the initial jump should gradually increase, and when the lever is released, it should gradually decrease.

- 15. Supply air under pressure P12 = 0.75 mPa (7.5 kgf/cm 2) to terminal 12. Move the lever all the way. In this case, the pressure in terminal 22 should change from 0 to 0.75 MPa (7.5 kgf/cm 2).

- 16. Supply air under pressure P11 = 0.75 mPa (7.5 kgf/cm 2) to terminal 11. Move the lever all the way. In this case, the pressure in terminal 21 should change from 0 to 0.75 MPa (7.5 kgf/cm 2).

- 17. Check the device for leaks. The tap must be sealed in any position of the lever.

Check with the lever released and pressure P11 = P12 = 0.75 MPa (7.5 kgf/cm 2) in terminals 11 and 12 and with the lever pressed all the way and pressure P = 0.75 mPa (7.5 kgf/cm 2) in terminal 11.

Air leakage in each case should not exceed 8 cm 3 /min.

The brake valve drive is adjusted correctly if the full travel of the brake pedal, determined by the movement of the center of the pedal pad, is 105-117 mm.

In this case, the pedal platform should not touch the floor in the extreme pressed position, and the brake valve should be fully open.

Pedal free play 18-25 mm.

The free play of the brake pedal is determined by the design of the brake valve.

If necessary (when removing and installing a faucet), you can adjust it by rotating the fork along the thread of the rod, aligning the hole in the fork with the hole in the faucet lever, which is in a free state, and unscrewing the fork from the rod one turn.

In this position, install the fork pin, pin the pin and tighten the fork lock nut.

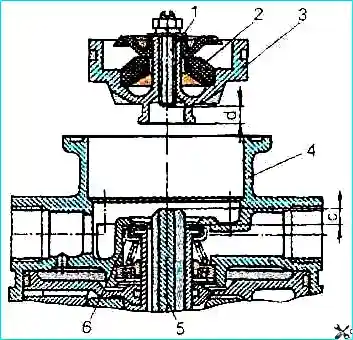

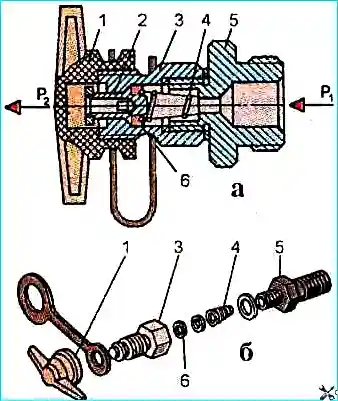

Control output valve (Fig. 9) is designed for connecting control and measuring instruments to the drive for the purpose of checking pressure ki.

The bus has three valves: one on the right front and two on the right rear brake chambers.

To connect to the valve, use hoses and measuring instruments with a union nut M16x1.5.

To disassemble the control outlet valve, clamp it in a vice at fitting 5 and unscrew the protective cap 1.

Unscrew housing 3, remove spring 4 and remove valve 6.

The valve is assembled in the reverse order.

To check the functionality of the valve, install it on a test bench and connect it according to the diagram shown in Fig. 9a.

Apply air under pressure of 0.75 MPa to terminal 1 (P1) and press and release the valve pusher three times.

Check the valve for leaks.

Then connect a 0.5 liter capacity to pin 1(P2).

Recess the valve pusher. In this case, the pressure in terminals 1 and 11 should become equal within no more than 5 s.

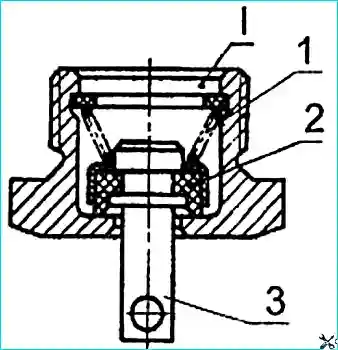

Condensate drain valve (Fig. 10) is designed for forced draining of condensate from the air receiver of the brake drive, and also, if necessary, for releasing compressed air from the receiver.

The condensate drain valve opens when you press pusher 3 up or move it in any direction.

When servicing the pneumatic drive of the bus brake system, the tightness of the system as a whole and its individual parts is checked.

Places of strong air leakage are determined by ear, and places of weak leakage are determined using soap emulsion.

An air leak in the service brake system is determined when the system is filled to operating pressure and the brake pedal is pressed.

In this case, the pressure drop should not exceed 0.05 MPa (0.5 kgf/cm 2) for 15 minutes and 0.05 MPa (0.5 kgf/cm 2) for 30 minutes with the controls in the free position.

An air leak in the parking brake system is detected when the handbrake handle is in the “Unbraked” position.

Air leakage from pipeline connections is eliminated by tightening or replacing individual connection parts.

To avoid breakage of the connecting bosses on brake pneumatic devices, the tightening torque of fittings, plugs, and nuts should not exceed 30...50 Nm (3-5 kg/cm 2).

In order to increase the reliability and reliability of the brake system, it is recommended to carry out preventive disassembly of the brake valve once every two years; brake chambers of rear and front brakes, safety valve; manual brake valve; quick release valve; replacement of a replacement dryer cartridge, regardless of their technical condition.

Faulty devices discovered during a control check must be repaired using repair kits and checked for operability and compliance with specifications.

The procedure for assembling and testing the devices is set out in special instructions. Their repairs are carried out by persons who have undergone the necessary training.