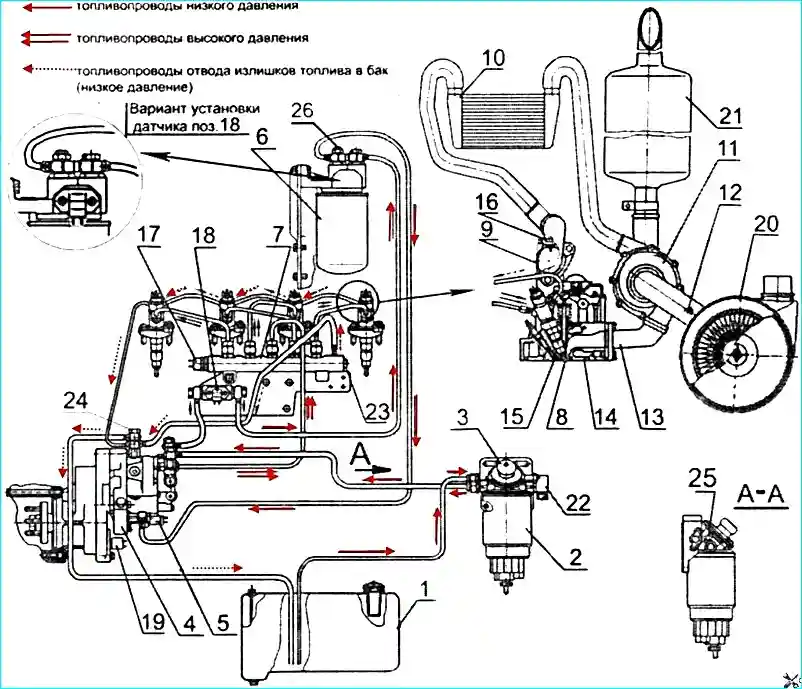

The diesel power system consists of a Common RAIL accumulator injection system, low and high pressure fuel lines, intake and exhaust manifolds; turbocharger; fine and coarse fuel filters, air cleaner, fuel tank, charge air cooler

Power system diagram: 1 - fuel tank; 2 - fuel coarse filter; 3 - manual fuel priming pump; 4 - high pressure fuel pump; 5 - electromagnetic pressure regulator, 6 - fine fuel filter; 7 - high pressure fuel accumulator; 8 - nozzle; 9 - intake manifold; 10 - charge air cooler 11 - turbocharger; 12 - air filter clogging sensor; 13 - exhaust manifold; 14 - cylinder head; 15 - glow plug; 16 - charge air temperature and pressure sensor; 17 - high fuel pressure sensor: 18 - fuel temperature and pressure sensor; 19 - camshaft speed sensor; 20 - air cleaner; 21 - muffler; 22 - fuel heater; 23 - pressure limitation valve; 24 - angle rotating bolt; 25 - air release plug; 26 - plug

The Common RAIL accumulator injection system consists of a fuel pump, an injector, a high-pressure fuel accumulator, speed sensors (crankshaft and camshaft), sensors for the state of the working environment (pressure and temperature of fuel and air), electromagnetic actuators (regulator fuel pressure, injector solenoid valves), electronic unit, control and communication control circuits, control and diagnostic panel.

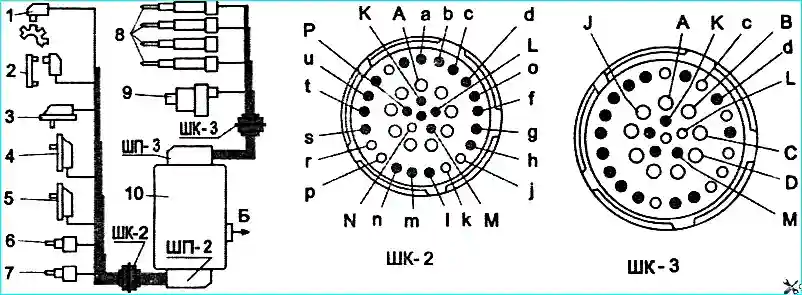

Common RAIL monitoring and control circuit diagram: 1 - crankshaft speed sensor; 2 - camshaft speed sensor; 3- fuel temperature and pressure sensor; 4 - temperature and oil pressure sensor; 5 - charge air temperature and pressure sensor; 6 - high fuel pressure sensor; 7- coolant temperature sensor; 8 - nozzles; 9 - pressure regulator; 10 - electronic control unit; B - in the diagram of the bus on-board network

The circuit diagram of the monitoring and control circuits of the COMMON RAIL power supply system is shown in Fig. 2.

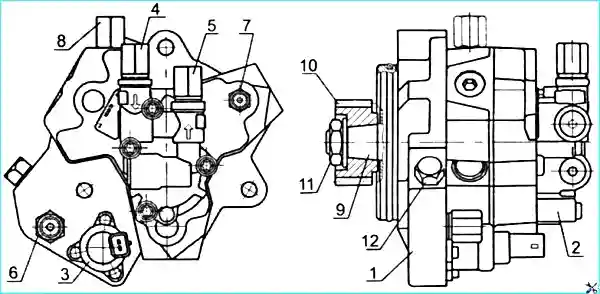

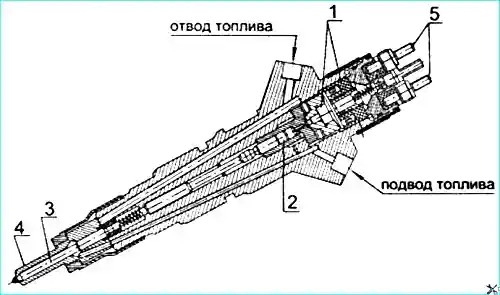

The high-pressure fuel pump (HPF, mod. CP3.3, Fig. 3) is designed to create a fuel reserve, maintain and regulate pressure in the fuel accumulator.

High pressure fuel pump SRZ.Z: 1 - high pressure fuel pump; 2 - fuel priming pump; 3 - electromagnetic pressure regulator; 4 - fuel supply fitting from the fuel coarse filter; 5 - fuel outlet fitting to the fine fuel filter; 6 - fuel supply fitting from the fine fuel filter; 7 - fuel outlet fitting to the fuel accumulator; 8 - fuel outlet fitting to the tank; 9 - drive shaft; 10 - drive gear; 11 - nut; 12 - plug

Fuel priming pump 2, driven by shaft 9, and electromagnetic pressure regulator 3 are attached to the injection pump body.

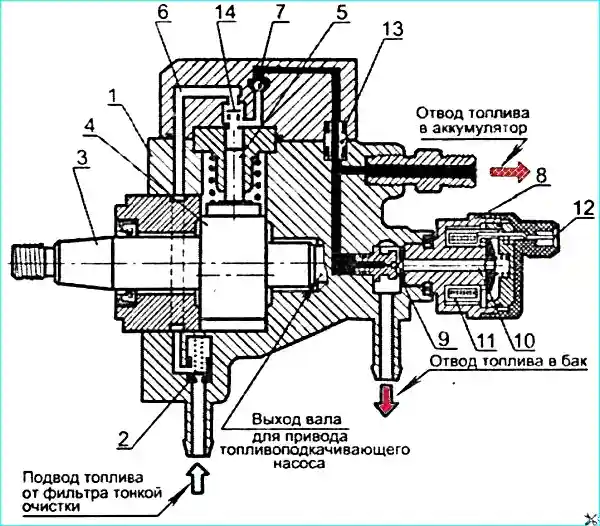

Injection pump diagram: 1 - fuel injection pump housing; 2 - safety valve with throttle hole; 3 - drive shaft; 4 - cam rotor; 5 - plunger; 6 - supply channel; 7- exhaust valve; 8 - pressure control valve; 9 - ball; 10 - anchor; 11 - electromagnet; 12 - electromagnet terminals; 13 - seal; 14 - inlet valve

In the injection pump housing, three plungers 5 are located radially at an angle of 120° (Fig. 4), and a cam rotor 4 is installed on the drive shaft 3 (the cams are located at 120° intervals around the circumference of the rotor).

The drive shaft of the injection pump with a cam rotor has a gear drive from a gearbox, the input shaft of which, through the drive half-coupling, is in kinematic connection with the diesel crankshaft through the distribution gears.

Fuel that has passed through a coarse fuel filter with a moisture separator is supplied under a pressure of 0.8-0.9 mPa by a fuel priming pump through a fine fuel filter to the inlet fitting of the injection pump.

Lubrication and cooling of fuel injection pump parts is carried out by diesel fuel entering the injection pump.

Under the influence After the created pumping pressure, safety valve 2 allows fuel access through supply channel 6 into the above-plunger spaces.

The advancing cam of the rotor moves the plunger upward, while the inlet of the inlet channel is closed and with further lifting of the plunger, the fuel is compressed into the space above the plunger.

When the increasing pressure reaches a level corresponding to that maintained in the high-pressure accumulator, release valve 7 opens.

Compressed fuel enters the high pressure circuit.

The plunger supplies fuel until it reaches TDC (feed stroke).

Then the pressure drops, the outlet valve closes. The plunger begins to move downwards. For one revolution of the shaft, each (out of three) plunger makes one pumping stroke.

Since the injection pump is designed for a large flow rate, at idle and at partial loads an excess of compressed fuel occurs, which is returned to the fuel tank through the pressure control valve 8 and the return line.

The pressure control valve sets the pressure in the high-pressure accumulator depending on the engine load, engine speed and thermal state of the engine.

If the pressure in the accumulator is too high, the valve opens and some of the fuel from the accumulator

discharged via the return line back to the fuel tank.

The pressure control valve is attached via a flange to the injection pump housing.

Anchor 10 presses valve ball 9 to the seat under the action of the valve spring so as to separate the high and low pressure circuits.

The switched on electromagnet 11 moves the armature, applying additional force to press the ball to the seat.

The entire anchor is washed with fuel, which lubricates the rubbing surfaces and removes excess heat.

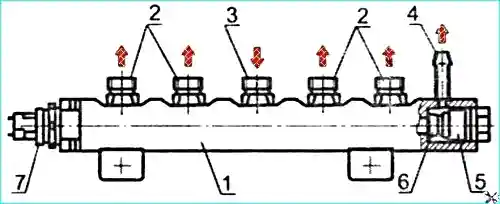

High pressure fuel accumulator (rail): 1- high pressure fuel accumulator; 2 - outlet fittings; 3 - supply fitting; 4 - return drain fitting; 5 - pressure limitation valve; 6 - valve core shut-off cone; 7 - fuel pressure sensor

The high-pressure fuel accumulator (Rail) is a high-pressure fuel accumulator (Fig. 5).

At the same time, the battery smoothes out pressure fluctuations that arise due to the pulsating fuel supply from the injection pump, as well as due to the operation of the injectors during injection due to the non-synchronism of the pressure pulses of the fuel doses coming from the injection pump and consumed through the injectors, as well as due to the excess mass of fuel located in the battery and playing the role of a damper for pulses of small doses of fuel entering and expended.

Battery 1 generally has the shape of a pipe, at the ends of which a fuel pressure sensor 7 and a pressure limiting valve 5 are installed.

Along the generatrix of the pipe perimeter there is a fitting for connecting high-pressure fuel lines 2; 3 and return drain fitting 4.

Fuel from the injection pump is directed through the high pressure line to the inlet fitting of stage 3

The fuel accumulator communicates with the injectors via high-pressure fuel lines connected to the accumulator outlet fittings.

The battery volume is constantly filled with fuel under pressure.

The value of this pressure is maintained at a constant level and can be adjusted by valve 8 (Fig. 5) depending on the operating parameters of the diesel engine.

The pressure limiting valve maintains a certain amount of pressure in the accumulator, acting as a pressure reducing (safety) valve.

The valve body on the battery side has a channel that is closed by the valve core cone 6.

The spring presses the cone tightly against the valve seat at normal operating pressure so that the accumulator remains closed.

If the pressure in the accumulator exceeds the operating value, the cone moves away from the seat under the influence of pressure and the fuel under high pressure is discharged into the return line. As a result, the fuel pressure in the battery decreases.

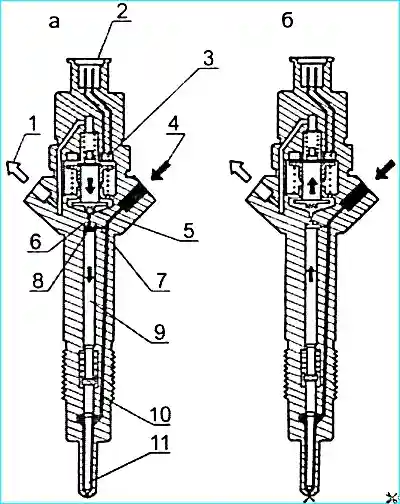

The nozzle (Fig. 6) is designed to inject fuel into the diesel cylinder and ensure the necessary fuel atomization.

Diesel engines use CRIN2 type injectors manufactured by BOSH (Germany).

The required timing of the start of injection and the amount of fuel supply are provided by the action of the injector solenoid valve.

Start moment vpr The search in angle-time coordinates is set by the electronic control system of the diesel engine.

The electronic unit generates injector control signals based on “reading” the signals generated by the crankshaft speed sensors and the input shaft of the fuel injection pump drive gearbox (sensors 1 and 2 in Fig. 2.), installed in a coordinated relationship according to a certain scheme.

Schematic diagram of the nozzle operation: 1 - fuel return line; 2 - electrical connection terminals; 3 - solenoid valve; 4 - high pressure line; 5 - valve ball; 6 - fuel outlet throttle opening; 7 - fuel supply throttle opening; 8 - control valve chamber; 9 - piston that controls the valve; 10 - channel for supplying fuel to the atomizer; 11 - needle and spray

The principle of operation of the nozzle is shown in Figure 7.

Fuel is supplied through the high-pressure line through the supply channel 4 to the injector nozzle 11, as well as through the fuel supply throttle opening 7 into the control valve chamber 8. Through the fuel outlet throttle opening, which can be opened by an electromagnetic valve, the chamber is connected to the return line plum 1.

When throttle hole 6 is closed, the hydraulic force acting from above on the control valve piston exceeds the force of fuel pressure from below on the nozzle needle cone.

As a result, the needle is pressed against the nozzle seat and tightly closes the nozzle holes. As a result, fuel does not enter the combustion chamber.

When the solenoid valve 3 is activated, the armature of the electromagnet moves upward, opening the throttle hole 6.

Accordingly, both the pressure in the control valve chamber and the hydraulic force acting on the control valve piston are reduced.

Under the influence of fuel pressure on the cone, the nozzle needle moves away from the seat, so that the fuel enters the combustion chamber of the cylinder through the nozzle holes.

Control supply is an additional amount of fuel intended for raising the needle, which, after use, is discharged into the fuel return line.

In addition to the control supply, there are fuel leaks through the nozzle needle and the control valve piston guide.

All this fuel is diverted into the return line, to which all other components of the injection system are connected, and returned to the fuel tank

The amount of injected fuel is proportional to the activation time of the solenoid valve and the pressure in the rail, and does not depend on either the engine speed or the operating mode of the fuel injection pump (time-controlled injection).

When the solenoid valve is de-energized, the armature is pressed down by the force of the valve closing spring and valve ball 5 closes the throttle hole.

After closing the fuel outlet throttle hole, the pressure in the control valve chamber again reaches the same value as in the battery.

This increased pressure forces the control valve piston down along with the spray needle.

When the needle fits tightly to the nozzle seat and locks its holes, injection stops.

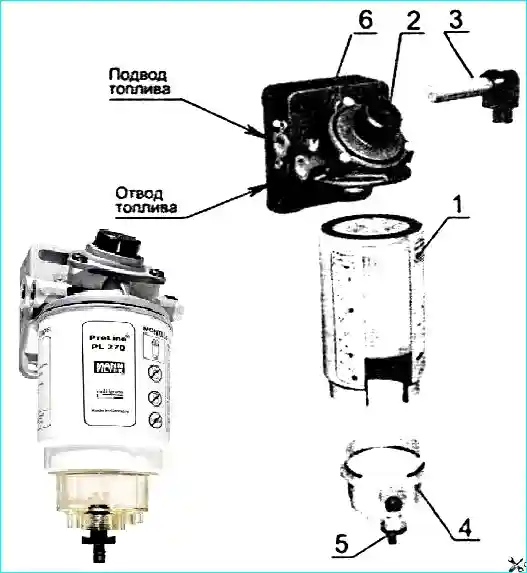

The fuel coarse filter is used to pre-clean fuel from mechanical impurities and water.

Due to the fact that the engine fuel injection pump is not equipped with a manual fuel priming pump, which is necessary to fill the fuel system with fuel without air, the filter design must contain a manual fuel priming pump.

Fuel coarse filter “Pre Line 270”: 1 - fuel coarse filter; 2 - manual fuel priming pump; 3 - fuel heater; 4 - moisture separator; 5 - water release valve; 6 - air release plug

In Fig. Figure 8 shows a fuel coarse filter with a manual fuel priming pump “Pre-Line 270”.

Sludge is drained from the filter through tap 5, located in the lower part of the moisture separator 4.

When operating a diesel engine at ambient temperatures below -25°C, the filter housing must be equipped with a fuel supply heater 3.

Heater supply voltage - 24 V, power - 350 W.

Connection: plus and ground. The heater operates autonomously and turns on and off automatically at temperatures below +5°C.

The fine fuel filter is used for final fuel purification. The fine filter is non-separable.

Fuel passing through paper curtains filter element is cleaned of mechanical impurities.

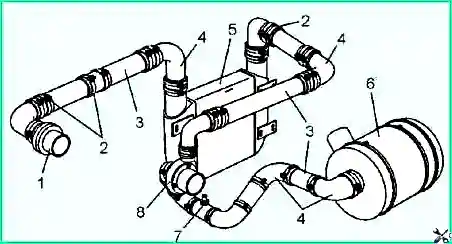

The diesel air supply system (Fig. 9) consists of an air filter, a turbocharger, a charge air cooler, pipes, pipelines and fastening clamps.

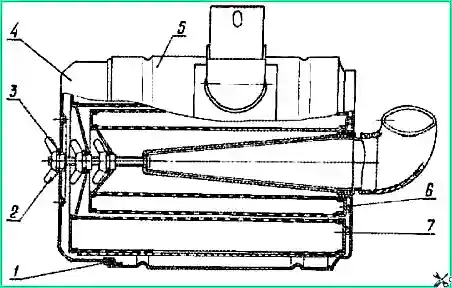

A dry type air filter with replaceable paper filter elements is used to clean the air entering the cylinders.

The air filter (Fig. 10) consists of a housing 5, two filter elements 6 and 7, a cover 4 to ensure tightness, and rubber gaskets.

A small (internal) filter element ensures air purification in the event of mechanical destruction of the outer filter element.

Attention! The influx of untreated air into the engine cylinders, which occurs due to depressurization of the intake tract, leads to a sharp decrease in engine service life.

To facilitate monitoring of air filter clogging, a sensor is installed between the filter and the turbocharger, and an indicator is installed on the instrument panel.

As the filter becomes clogged, the vacuum in the inlet pipeline increases and when it reaches a value of 6.5 kPa, the alarm is activated, and the “Air filter clogged” warning lamp lights up on the instrument panel.

When the lamp lights up, the filter element should be cleaned or replaced.

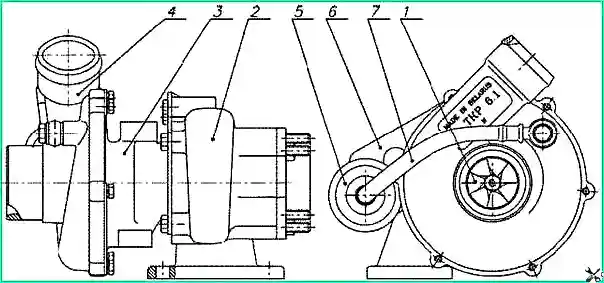

The turbocharger (Fig. 11) consists of a centrifugal single-stage compressor and a radial centripetal turbine.

Boost control occurs by bypassing part of the exhaust gases past the turbine wheel when the boost pressure exceeds a certain value.

A bypass valve is built into the turbine housing of the variable turbocharger.

The bypass valve lever is connected by an adjustable rod to an actuator connected by an air duct to the outlet pipe of the compressor housing.

Changing the length of the thrust of the turbocharger actuator during operation is not allowed.

Disassembly and repair of the turbocharger during operation is not allowed and must be carried out in a specialized repair shop.