The table shows the probable causes of brake system failure, as well as methods for eliminating failures

Probable cause (Method of elimination)

Air cylinders are not filled (the pressure regulator is activated):

- Clogged pipeline from the compressor to the pressure regulator

Clean the pipeline

- Damage to the pressure regulator valve

Replace the pressure regulator valve

Air cylinders are not filled to the lower pressure (the pressure regulator does not work):

- Leakage of compressed air from the pneumatic drive

Depending on the location of the leak: replace the pipeline, hose, or tighten the fittings of pipelines and hoses, or tighten the fasteners of the connecting elements, or replace the faulty device

- Compressor faulty

Repair or replace the compressor

The air tank of the rear brake circuit is not filled:

- The section of the four-circuit safety valve connected to the rear brake cylinder does not work or is not adjusted

Adjust or replace the device

The air tank of the front brake circuit is not filled:

- The section of the four-circuit safety valve connected to the front brake cylinder does not work or is not adjusted

Adjust or replace the device

The air cylinder of the parking brake system is not filled:

- The section of the 4-circuit safety valve connected to the parking brake system cylinder is not working or is not adjusted

Adjust or replace the device

Frequent operation of the pressure regulator:

- Leakage of compressed air from the pneumatic drive in the area from the regulator to the safety valve

Depending on the location of the leak: replace the pipeline, hose, or tighten the fittings of pipelines and hoses, or tighten the fasteners of the connecting elements, or replace the faulty device

Air tanks are filling slowly:

- Leakage of compressed air from the pneumatic drive due to leakage: at the junction of pipelines; damage to pipelines; at the joints of device body parts due to their damage; malfunction of the atmospheric terminals of the devices.

Depending on the location of the leak: replace the pipeline, hose, or tighten the fittings of pipelines and hoses, or tighten the fasteners of the connecting elements, or replace the faulty device

- The compressor is faulty due to wear or damage to parts

Repair or replace the compressor

The pressure in the air cylinders is above or below normal (the pressure regulator is activated):

- The pressure regulator is out of adjustment or the pressure gauge is faulty

Adjust the pressure regulator. Replace the pressure gauge.

Ineffective braking when pressing the brake pedal:

- Leakage of compressed air from the pneumatic drive

Depending on the location of the leak: replace the pipeline, hose, or tighten the fittings of pipelines and hoses, or tighten the fasteners of the connecting elements, or replace the faulty device

- Oiling the pad linings

Wash the linings with kerosene, replace the hub cuffs

- Large gap between the pads and the brake drum in one or more brake mechanisms

Check the strokes of the rods in all brake mechanisms and, if necessary, replace the adjusting lever

- The adjustment of the brake valve drive is broken

Adjust the brake valve drive

- Brake valve is faulty

Repair or replace the brake valve

- The working brake mechanisms are misaligned or faulty

Adjust or repair brake mechanisms

- Leakage of the brake chamber membrane

Replace the membrane

- Limitation of pedal travel due to contamination of the cavity under the rubber cover of the brake valve lever

Restore the stroke of the tap pusher; if necessary, replace the rubber boot

- The stroke of the brake chamber rods exceeds the set value

Adjust the stroke of the rods

When the parking brake valve is turned on, the rear wheels do not brake:

- Leakage of compressed air from the pneumatic drive in the drive circuit of the parking brake system

Depending on the location of the leak: replace the pipeline, hose, or tighten the fittings of pipelines and hoses, or tighten the fasteners of the connecting elements, or replace the faulty device

- The stroke of the rear wheel brake chambers is greater than normal

Adjust the stroke of the rods

- The brake chamber with spring energy accumulator is faulty

Replace the faulty device

- The brake valve of the parking brake system is faulty

Replace the faulty device

- Accelerator valve is faulty

Replace the faulty device

- Four-circuit safety valve is faulty

Replace faulty apparatus

The brake lights do not light up or go out when you press the pedal or apply the parking brake:

- The brake light sensors are faulty or the wiring is faulty

Replace the faulty sensor or repair the electrical wiring

- One of the pneumatic drive devices is faulty

Replace the faulty device

The wheels do not release the brakes after releasing the brake pedal when the parking brake is off:

- Adjustment lever failure

Replace lever

- The two-section brake valve is faulty or its drive is out of alignment

Adjust the tap drive or replace the tap

- The parking brake valve is faulty

Replace the faulty device

- Accelerator valve is faulty

Replace the faulty device

- The seal between the cavity of the spring energy accumulator and the working chamber is broken

Replace the brake chamber with spring energy accumulator

The rear wheels do not release when the parking brake is released:

- Leakage of compressed air from the pneumatic drive in the drive circuit of the parking brake system

Depending on the location of the leak: replace the pipeline, hose, or tighten the fittings of pipelines and hoses, or tighten the fasteners of the connecting elements, or replace the faulty device

One of the wheels does not release:

- Broken tension springs

Replace springs

- Jamming of the expansion fist shaft

Wash and lubricate the shaft with bushings

Presence of oil in the first air cylinder:

- Increased oil release from the compressor, which caused a failure of the dryer adsorbent element

Repair or replace the compressor. Replace the desiccant element

Presence of condensation in air cylinders:

- The dryer filter is clogged, the check valve of the regeneration cylinder is stuck, or the purge hole in it is clogged

Carry out maintenance of the dryer

Possible malfunctions of the pneumatic devices of the brake system

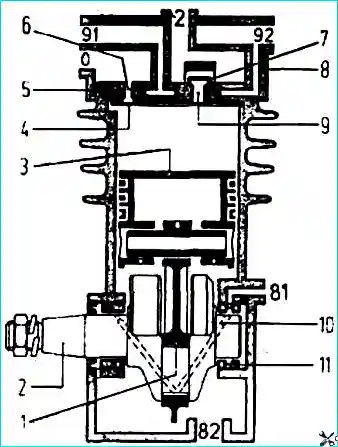

Compressor

The compressor does not develop the required pressure:

- Compressed air leaks in the pneumatic system

Check the condition of pipelines, pneumatic devices and their connections

- The head is loose

Tighten the head fastening nuts

- The gasket between the head and the valve plate is damaged

Replace gasket

- Coking of compressor valves

Clean the valves and valve plate from carbon deposits

- Wear of piston rings

Replace the rings and check the serviceability of the air filter

Noise when the compressor is running:

- Increasing the gaps between the connecting rod and the crankshaft journal

Replace connecting rods

- The response pressure of the membrane chamber is very high

Membrane defect 16. Replace membrane

- The chamber rod does not return to its original position after releasing air

Defective return spring 19. Replace the spring

- Actuation pressure of the spring energy accumulator

The working surface of cylinder 7 is damaged

- Seal 6 is swollen

Replace defective parts

When air is supplied, the spring energy accumulator does not decelerate:

- Seal 6 or ring 3 is leaking

Replace the O-ring and seal

- Compressed air passes through the connector of cylinder 7 and flange 14

Defective rubber sealing ring in the connector. Replace ring

The spring energy accumulator does not work efficiently:

- Spring defect 8

Replace the spring

High response pressure of the spring energy accumulator:

- The working surface of the cylinder is damaged

Replace cylinder

The energy accumulator spring does not compress when air is supplied to the cylinder. There is air outlet from the drainage holes of the brake chamber housing and from the opening of the chamber itself:

- The piston sealing ring is damaged

Replace ring

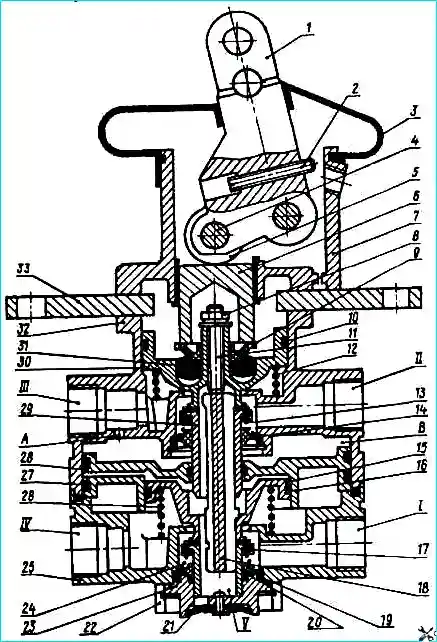

Brake valve

When valve lever 1 is free, air leaks into the atmosphere through outlet window 21.

Defects in valves 17, 29 and springs 13, 24.

Replace defective parts and clean valve seats

Air leakage at housing connector:

- O-ring defect

Replace ring

- Damage to the end surfaces of the housings.

Clean up the damaged area

As the pressure in the upper section increases, the pressure in the lower section slowly increases:

- Swelling of O-rings

Replace defective rings

Crane lever jammed:

- Contamination of the lever mechanism due to damage to the protective cover

Clean the parts of the lever mechanism from dirt, replace the defective cover

Violation of the following action along the lever:

- Defect of elastic element 31

Replace the elastic element

Parking brake valve

Air leakage into the atmosphere:

- Defect of the valve or its spring

Replace valve or spring

Violation of the following action of the crane:

- Breakage of the balancing spring. Swelling of the O-ring

Check and replace the spring or O-ring

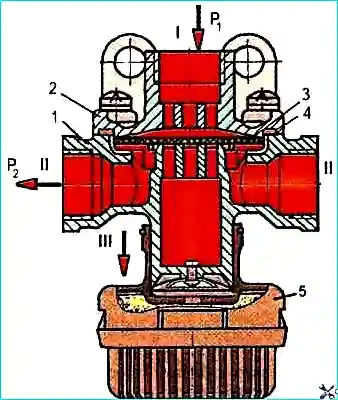

Quick release valve

Leakage of compressed air at the connector of the cover and housing:

- Defective sealing ring 4

Replace ring

- Cover 2 is loose

Tighten the screws

When compressed air is supplied to the outlet / air is released into the atmosphere:

- Aperture defect 3

Replace the diaphragm

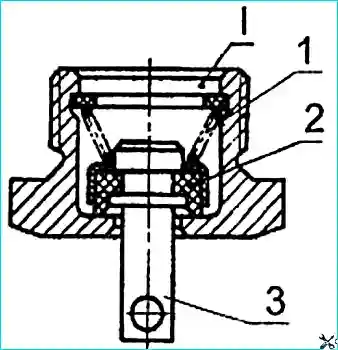

Test outlet valve

Valve leakage:

- Seal defect on pusher 5

Replace the seal

- Defect in the sealing gasket between fitting 1 and body 2

Replace gasket

Condensate drain valve

Tap leakage:

- Valve 2 or housing is dirty or defective

Operate the crane. Clean the valve or body

Air leak from under the valve body gasket

- Defects (nicks, burrs, etc.) on the sealing gasket, the ends of the valve or the receiver boss

Replace the gasket or condensate drain valve. Clean the end of the receiver boss