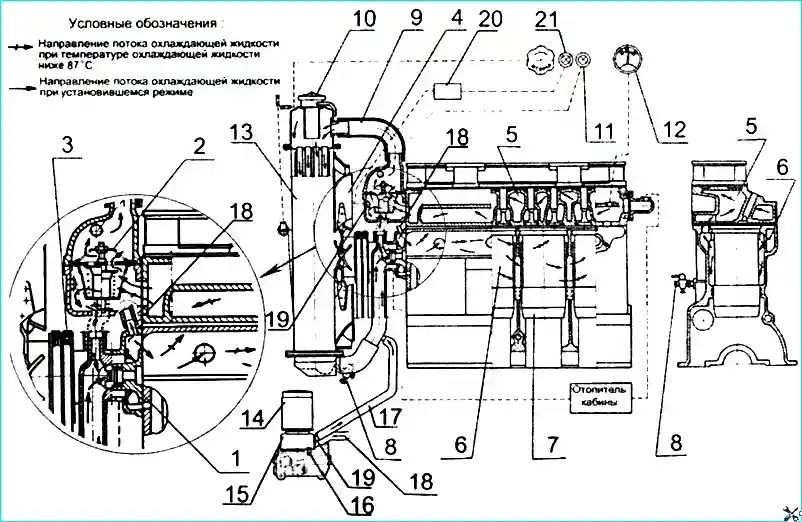

Closed-type engine cooling system, with forced circulation of coolant from a centrifugal pump

The temperature of the coolant in the system is controlled using a remote thermometer, the sensor of which is installed in the cylinder head.

In addition, a light sensor for emergency coolant temperature is installed in the thermostat housing cover.

Attention! It is prohibited to operate a diesel engine when the warning light for emergency coolant temperature in the cooling system comes on.

The temperature of the coolant in the cooling system must be maintained between 85 and 95° C.

To speed up the warm-up of the diesel engine after start-up and automatically regulate the temperature regime at various loads and ambient temperatures, a thermostat is used with a temperature at which the main valve begins to open at 87±2 °C.

Thermostat with solid filler is designed to accelerate engine warm-up after starting automatic temperature control at various loads and ambient temperature.

The expansion tank is designed to compensate for changes in the volume of coolant during heating and to remove air.

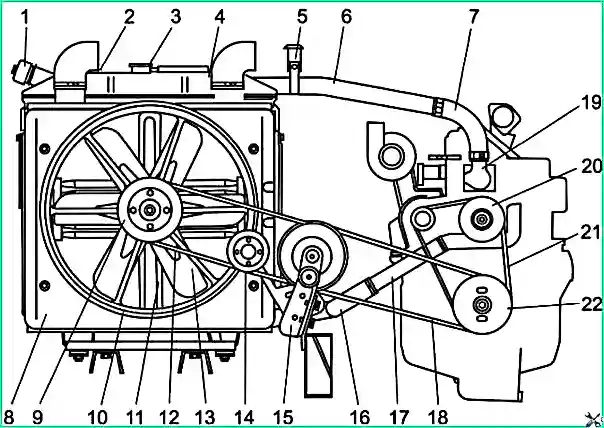

The liquid pump and generator are driven from the engine crankshaft pulley using two belts.

The engine cooling system fan is driven from the crankshaft pulley through the intermediate support pulley.

Attention! To avoid scale formation and damage to the engine, do not use water in the cooling system.

If malfunctions associated with a coolant leak occur, short-term use of water is allowed until the malfunction is eliminated.

Cooling system maintenance

When servicing the cooling system, the fluid level in the expansion tank is checked daily and the tightness of the connections is monitored.

It is not allowed to operate a bus with an empty expansion tank. The fluid level should be above the "MIN" mark on the reservoir body.

A low-freezing liquid should be used as a coolant in the system.

To avoid scale formation, do not use water in the cooling system.

If a coolant leak occurs, short-term use of water is allowed until the problem is eliminated.

The density of the low-freezing liquid should be monitored before the start of the cold period of the year, also after each repair of the cooling system associated with a coolant leak.

External signs (color, smell, etc.) do not allow you to correctly determine the quality of the coolant.

Once a year in the fall, when performing maintenance, the coolant should be replaced.

Before replacing the fluid, you need to make sure the system is tight.

Attention! The use of coolant of insufficient density can cause engine destruction.

Monitor the coolant temperature. Normal operating temperature should be 85-95°C

If the temperature rises above the operating temperature, check the coolant level in the expansion tank and, if necessary, in the radiator, check the tightness of the radiator and pipelines, check the tension of the fan belts and their condition.

If necessary Therefore, but at least every 120 thousand km of the bus, flush the cooling system to remove contaminants.

For rinsing, use a solution of 50-60 grams of soda ash per 1 liter of water.

Rinse the system in the following order:

- - pour 2 liters of kerosene into the radiator and fill the system with the prepared solution;

- - start the diesel engine and run for 8-10 hours or 350-400 km, then drain the solution and rinse the cooling system with clean water.

The tension of the fan belt between the crankshaft pulley and the intermediate support is performed by turning the eccentric axis of the intermediate support after loosening the nuts securing it.

The tension of the belt between the fan pulleys and the intermediate support is carried out by a tension roller.

Tension of the generator and water pump drive belts is done by turning the generator housing.

The compressor drive belt on the D-245.9EZ diesel engine is tensioned with a roller through the tension mechanism.

Before tensioning, loosen the tension roller shaft locking bolt and the adjusting screw locking nut.

Then rotate the nut on the adjusting screw to move the screw together with the tension roller.

Tension control is carried out using a spring dynamometer based on the amount of belt deflection or using the KI-8920 device.

Belt deflection under a load of 4±0.2 kgf should be:

- - in the area between the crankshaft pulleys and the intermediate support - 14-20 mm;

- - in the area between the intermediate support pulleys and the fan shaft - 13-18 mm.

- - in the area between the crankshaft and generator pulleys - 15-22 mm;

- - in the area between the generator and water pump pulleys - 7-12 mm.

- - in the area between the crankshaft and compressor pulleys - 15-22 mm;

If one of the belts is worn or damaged, replace it as a complete set (both belts).

Litol-24 lubricant is placed in the bearing cavity of the water pump during assembly and is replaced only after repair (disassembly) of the unit.

The bearings of the water pump, fan shaft and intermediate fan support do not require lubrication during the entire period of operation.