Gearbox manufactured by JSC "SAAZ AMO ZIL" - mechanical, five-speed, synchronized, with a central control lever, with direct or overdrive fifth gear

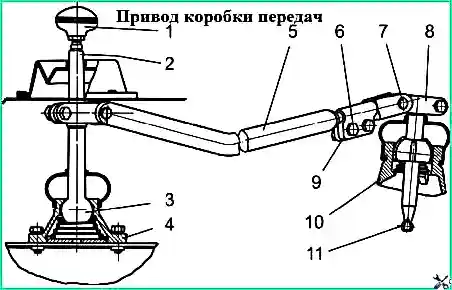

The gearbox lever is connected by a rod to the gear shift lever at the driver's workplace.

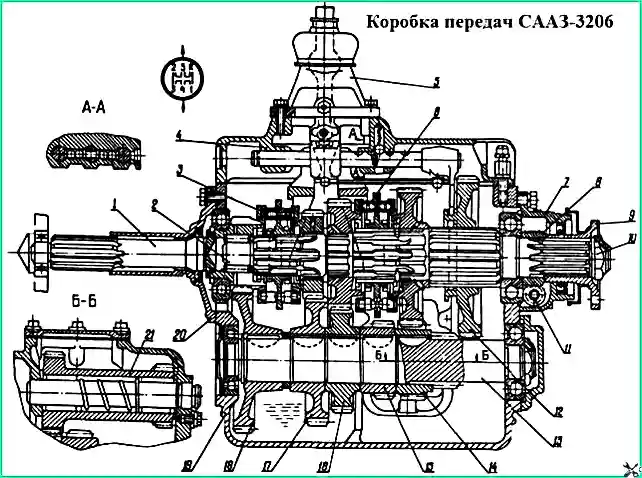

The design of the gearbox and its drive is shown in Fig. 1 and fig. 2

Gearboxes of the following models can be installed on the bus: SAAZ-3206, SAAZ-320670, SAAZ-132A2, SAAZ-132M3.

The new family of SAAZ-136 gearboxes has an increased service life and the following differences from the SAAZ-3206:

- - all gears on the secondary shaft are mounted on needle bearings;

- - the intermediate shaft gears have a keyless fit on the shaft due to interference;

- - the intermediate shaft is mounted on tapered bearings, the tightening of which is regulated by a special nut;

- - the SAAZ-136M has clutch synchronizers installed in all gears, the SAAZ-136A has finger synchronizers with steel cone rings coated with molybdenum;

- - a contactless speedometer sensor is installed.

For better use of performance properties, it is recommended to use buses with gearboxes with an accelerating 5th gear on suburban routes, and buses with gearboxes with a direct 5th gear on city routes.

For oil filling there is a filler screw plug in the right wall of the crankcase 19.

To drain the oil, there is a drain hole in the left wall of the crankcase, at the bottom, closed with a magnetic screw plug.

The box is centered along the flange of the input shaft cover 20.

Gear changes are made by the control mechanism lever in the cover 4 (Fig. 1) of the gearbox through rod 5 (Fig. 2) and gear shift lever 2 at the driver’s workplace.

If it is difficult to shift gears, it is recommended to adjust the drive by changing the length of the rod 5 by turning the fork 9 of the gear shift rod.

When servicing the gearbox, its fastening to the clutch housing and the fastening of the parts of the gearbox itself to the crankcase are checked; The oil level is replaced and maintained according to the lubrication chart.

When changing the oil, you need to clean the drain plug magnet and the breather.

A clogged breather can cause an oil leak due to increased pressure in the crankcase.

When changing the oil, as well as when repairing the gearbox, do not allow contaminants to get into it, which can cause the gears to jam.

Possible gearbox malfunctions and methods of elimination

Difficulty engaging all gears

- Incomplete disengagement of the clutch (clutch “drives”)

Adjust clutch pedal free play

Shifting gears with a bang and a grinding noise

a) wear of synchronizer cone rings

Replace synchronizers

b) wear of the locking chamfers of the pins and carriage

Replace synchronizers

Self-switching gears on the go

a) incomplete gear engagement due to a faulty switching mechanism

Troubleshoot

b) wear of forks

Replace worn parts

c) loosening of forks and heads

Tighten the fastening

Gears are not included

- Breakage of pins and synchronizer clamps

Replace synchronizers

Increased noise during gearbox operation

a) loosening of fasteners

Tighten fasteners

b) wear and breakage of gear teeth

Replace worn parts

Oil leak from gearbox

a) wear and tear or loss of elasticity let

Replace cuffs

b) increased pressure in the crankcase

Blow out the breather

c) violation of tightness along sealing surfaces

Tighten fasteners, replace gaskets