KAMA3-740.50-360, KAMA3-740.51-320 engines, designed for installation on single vehicles and truck tractors used as part of road trains, supplied to the domestic market and for export to countries with a moderate and tropical climate, as well as supplied as spare parts

Engines manufactured in the "U" version according to GOST 15150-69 are designed for operation at ambient temperatures from minus 45 to plus 40 °C, relative air humidity up to 75% at a temperature of 15 °C and in areas located at an altitude of up to 3000 m above sea level with a decrease in power, economic and other indicators to 20%, with overcoming passes up to 4500 m.

Engines manufactured in the "U" version according to GOST 15150-69 are designed for operation at ambient temperatures from minus 45 to plus 40 °C, relative air humidity up to 75% at a temperature of 15 °C and in areas located at an altitude of up to 3000 m above sea level with a decrease in power, economic and other indicators to 20%, with overcoming passes up to 4500 m.

Engines manufactured in the "U" version according to GOST 15150-69 "T" according to GOST 15150-69, designed for operation at ambient temperatures from minus 10 to plus 45 °C, relative air humidity up to 80% at a temperature of 27 °C and in areas located at an altitude of up to 3000 m above sea level with a decrease in power, economic and other indicators to 20%, with overcoming passes up to 4500 m.

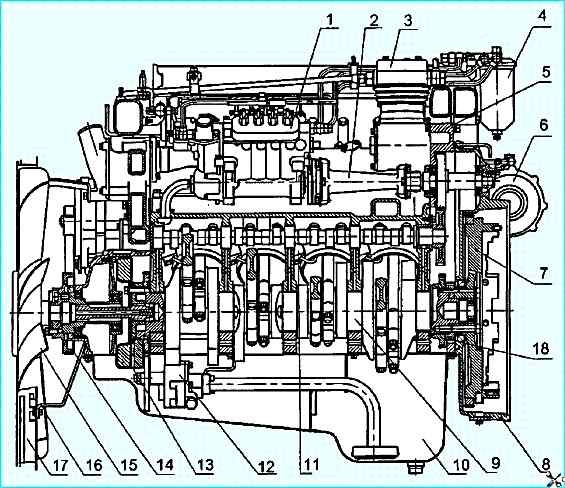

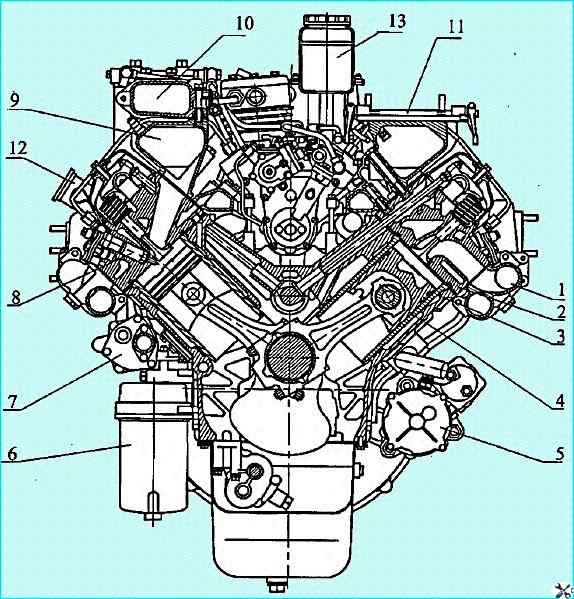

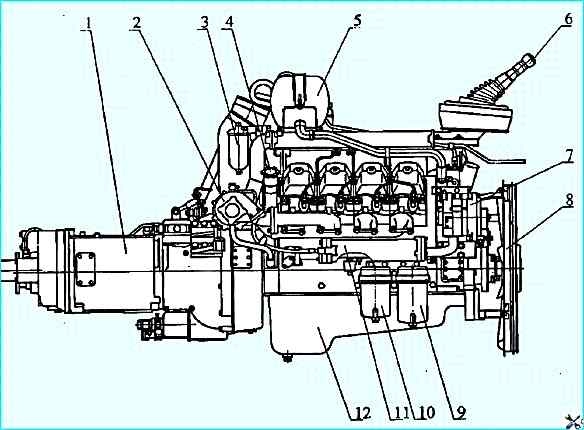

The general view, longitudinal and cross sections of the engines are shown in the figures 1-5.

Longitudinal section of the engine: 1 - high-pressure fuel pump; 2 - high-pressure fuel pump drive; 3 - compressor; 4 - fine fuel filter; 5 - accessory housing; 6 - turbocharger; 7 - flywheel; 8 - flywheel housing; 9 - crankshaft; 10 - oil sump; 11 - piston cooling nozzle; 12 - oil pump; 13 - torsional vibration damper; 14 - water pump and generator drive pulley; 15 - fan with viscous coupling. 16 - fan cowl mounting bracket; 17 - fan cowl: 18 - oil scavenge pump drive gear

Engine cross-section: 1 - exhaust manifold; 2 - cylinder head; 3 - cylinder block; 4 - piston; 5 - starter; 6 - oil filter; 7 - water-oil heat exchanger; 8 - injector; 9 - intake manifold; 10 - supply pipe; 11 - fuel injection pump regulator control drive; 12 - oil filler neck; 13 - power steering pump reservoir

Power unit, right side view: 1 - gearbox; 2 - turbocharger; 3 - fuel filter; 4 - oil filler neck; 5 - expansion tank; 6 - gear shift lever; 7 - generator: 8 - fan housing: 9 - full-flow oil filter; 10 - partially in-line oil filter; 11 - water-oil heat exchanger; 12 - oil sump

Four-stroke engines with compression ignition, liquid cooling, with a V-shaped arrangement of eight cylinders, with turbocharging and intermediate air cooling (IAC) of the "air-to-air" type.

In terms of emissions of harmful substances with exhaust gases, the 740.50-360 and 740.51-320 engines comply with the requirements of the UNECE regulations (EURO-2).

The basic part of the engines is the cylinder block, on which the units and parts of the engine are installed and secured. "Wet" type cylinder liners are installed in the bore of the half-blocks

The cylinder liners are closed from above by heads, separate for each cylinder. The cylinder block is closed at the bottom by a stamped oil sump.

The camshaft is located in the cylinder block on five plain bearings. The crankshaft is installed in the lower part of the block.

The engine cooling system is liquid, closed type, designed for the use of low-freezing coolant.

Technical characteristics of the engine 740.50-360, 740.51-320

Parameter name - Value

Engine type - Four-stroke, with compression ignition

Cylinder arrangement - V-shaped, with a 90° camber angle

Cylinder firing order - 1-5-4-2-6-3-7-8

Direction of crankshaft rotation - right (counterclockwise, when viewed from the flywheel side)

Cylinder diameter and piston stroke, mm: 120x130

Working volume, l: 11.76

Nominal power, kW (hp): 265 (360); for engine 740.51-320: 235 (320)

Maximum torque, Nm (kgf m): 1470 (150); for engine 740.51-320: 1275 (130)

Installation fuel injection advance angle, degrees: 9+1

Compression ratio 16.8 (±2)

Crankshaft speed, min -1:

- - nominal 2200±50

- - at maximum torque 1300-1500

at idle:

- - minimum 600±20

- - maximum 2530-80

Number of valves in the cylinder head - 2 (inlet and outlet)

Clearances on a cold engine, between rocker arms and rods valves:

- - inlet - 0.25...0.30 mm;

- - outlet - 0.35...0.40 mm.

Oil pressure in a warm engine at crankshaft speed, kPa (kgf/cm 2):

- - nominal 392...539 (4...5.5)

- - minimum idle, not less than 98 (1)

Injector, type - 273

Models 273.1112010-20 (273-20)

Nozzle manufactured by "YAZDA" model 273.1112010-20 or 273.1112010-50 (273-50)

or models

Nozzle manufactured by BOSCH DLLA 148 S 1380

Injector injection start pressure, MPa (kgf/cm2): 23.73...24.90 (242...254)

High-pressure fuel pump (HPFP) model 337-20.04; for engine 740.51-320: 337-20.03

Boost system - gas turbine with two turbochargers and air-to-air NVG.

Generator model G-273V or 6582.3701 (in accordance with the design documentation) - three-phase synchronous, alternating current, with a built-in rectifier unit

Generator G-273V:

- - rated current, A; 28

- - rated rectified voltage, V; 28

- - rated power, kW. 0.8

Generator mod. 6582.3701:

- - rated current, A; 75

- - rated rectified voltage, V: 28

- - rated power, kW. - 2.0

Starter 5662.3708 direct current, series excitation, with electromagnetic drive

- nominal power, kW 8.2

Gearbox model 161 mechanical, eight-speed;

or

Gearbox model ZF-16S151 of the company "ZAHNRADFABRIK" mechanical, sixteen-speed, includes a main four-speed box with a built-in two-stage divider located in front of the main box and with a two-stage planetary demultiplier located behind the main box.

Possible malfunctions and troubleshooting methods

Malfunction

- Cause of malfunction

Method troubleshooting

Engine

Engine won't start

- No fuel in tank

Fill fuel tank, bleed fuel system.

- Air in fuel system

Fix leak, bleed system.

- Incorrect fuel injection advance angle adjustment

Adjust angle.

- Freezing of water that got into fuel lines or on fuel tank intake screen

Carefully warm up fuel filters, lines and tank with rags soaked in hot water or steam, do not use open flame for heating

Engine does not develop required power, runs unstably, smoke during operation

- Clogging air cleaner or air intake cap

Carry out maintenance of the air cleaner or clean the cap mesh

- Insufficient fuel supply

Replace the fine fuel filter elements, flush the coarse filter, tighten the connections in the fuel pipes.

- Incorrect fuel injection advance angle adjustment

Adjust the angle.

- Clogged injector (coking of nozzle holes, stuck needle) or incorrect adjustment.

Flush the injector, replace the nozzle if necessary, check and adjust if necessary.

- Incorrect adjustment of the governor control lever drive (the control lever does not reach the maximum crankshaft speed limiting bolt).

Check and adjust the governor drive.

- Broken spring of the injection pump pusher.

Replace the spring and adjust the pump on the bench.

- Dirt between the seat and the valve of the fuel injection pump or breakage of the spring.

Flush the valve or replace the spring, check the operation of the pump on the bench.

- Violation of the tightness of the injection pump discharge valves or breakage of the spring.

Remove the leak in the valve in the workshop or replace the spring.

- Jamming of the plunger of the injection pump section

Replace the plunger pair and adjust the pump.

- Violation of the adjustment of thermal clearances in the valve timing mechanism.

Adjust the clearances.

- Depressurization of the membrane cavity or damage to the membrane of the corrector for the boost pressure air.

Restore the tightness of the membrane cavity or replace the damaged membrane.

- Stop supplying oil to the corrector due to the boost air pressure.

Restore by oil supply to the corrector.

- Loose fastening or breakage of the high-pressure tube.

Tighten the fastening nut or replace the tube.

- Poor compression due to piston group malfunctions or loose fit of the valve timing to the seats.

Check the condition of the pistons and piston rings, grind the valves.

- Thickening of the fuel (in the cold period of time).

Replace the elements of the fine fuel filter, replace the fuel with the appropriate season, bleed the fuel system.

Low pressure of the supercharged air:

- air leakage through the connections of the intake manifold with the cylinder heads, pipes, turbochargers and compressor;

Tighten the connections, if necessary, replace the gaskets and connecting hoses.

- gas breakthrough in the connections of the exhaust manifold and turbine housing;

Tighten the connections, replace the gaskets if necessary.

- turbocharger rotor seizure;

Replace the turbocharger.

- contamination of the exhaust tract, flow parts of the compressor and turbine.

Clean the pipelines, remove the turbocharger, and remove deposits from the flow parts.

Extraneous noise in the turbocharger

- Rotor rubbing against body parts

Tighten the bolts securing the turbine and compressor housings.

Check for rotor rubbing at its extreme positions.

If the rotor rubs, replace the turbocharger. If the noise persists, remove the turbocharger for maintenance.

High-frequency noise (whistle)

- The tightness of the engine intake and exhaust tracts is broken

Tighten the bolts and nuts securing the system components, replace the gaskets if necessary.

Increased oil consumption

- Long-term engine operation at idle speed.

Do not operate the engine at idle speed unless necessary.

- Oil leakage through the connections in the turbocharger lubrication system.

Tighten the connections, replace the gaskets and rubber sleeves if necessary.

- Wear of the valve-bushing mating in the cylinder head, aging of the rubber valve cuff.

Check and replace worn parts.

- Clogged air cleaner or air intake cap.

Service the air cleaner and clean the cap mesh.

Lower oil pressure in the lubrication system

- Low oil level in the oil pan.

Check and, if necessary, top up oil to the "B" mark.

- Malfunction of pressure control devices

Make sure that the devices are in good working order.

- Use of oil of the wrong viscosity

Change the oil to one that meets the chemotological chart.

- Contamination of the filter elements of the oil filter

Replace the filter elements.

- Maladjustment or jamming of the relief valve or lubrication system valve

Check the valves and eliminate jamming, adjust or replace faulty parts if necessary.

- Clogged oil pump intake

Flush the intake.

- Coolant entering the oil

Check the tightness of the water cavity, cylinder liner seal, tightness of the water-oil heat exchanger, replace faulty parts.

- Oil leaks at joints and oil lines of the lubrication system

Check the condition of process plugs, plugs, tightening of fasteners at joints, condition of sealing rings and gaskets.

- Malfunction of the oil pump

Remove the pump and check its operability on a special stand.

- Unacceptable increase in clearance in the crankshaft and camshaft bearings

Make repairs engine.

The oil temperature alarm comes on

- Malfunction of the oil temperature alarm sensor

Make sure the sensor is working properly, replace if necessary.

- Jamming of the heat exchanger switching thermal valve, malfunction of the thermal power sensor

Check the operation of the heat exchanger switching thermal valve, if necessary, eliminate jamming or replace the sensor.

- Clogged tubes or dirty cooling plates

Check the water-oil heat exchanger for clogged tubes and dirty cooling plates, flush or replace the heat exchanger if necessary.

Increased oil pressure in the lubrication system

- High oil viscosity.

Change the oil to the one corresponding to the chemotological chart.

- Loss of tightness of the control signal line connecting the main oil line with the pump or its blockage

Check the oil supply pipe to the pump, the tightening of the mounting bolts, the presence of a hole in the cover.

- Jamming or misadjustment of the lubrication system valve.

Check the valve and eliminate the jamming, replace faulty parts if necessary.

Knocking when engine operation

- Early fuel injection into the cylinders.

Adjust the fuel injection advance angle.

- Increased thermal clearances in the valve timing mechanism

Adjust the clearances.

- Wedging of the valve timing mechanism valves in the bushings (the piston touches the valve)

Disassemble and clean the valve mechanism. Replace the valve if necessary.

- Increased cyclic fuel supply (the rack retainer has disengaged)

Replace the fuel injection pump rack

A dull knock from the crankshaft. Frequency increases with increasing crankshaft speed

- Unacceptable increase in clearance between journals and main bearing shells as a result of using oil that does not correspond

to that specified in this manual, or reducing oil pressure and supply.

Grind journals to the repair size and replace shells, change oil and check operation of oil pump.

- Unacceptable increase in clearance between thrust half rings and crankshaft.

Replace thrust half rings with new ones of greater thickness.

- Loosening of flywheel to crankshaft mounting bolts.

Establish cause and tighten bolts.

The knock of connecting rod bearings is sharper than the knock of main bearings. It is heard when the engine is idling and increases with increasing crankshaft speed

- Unacceptable increase in the clearance between the journals and the liners of the connecting rod bearings as a result of using oil that does not correspond to the specified one, or a decrease in oil pressure and supply.

Grind the journals to the repair size and replace the liners, change the oil and check the operation of the oil pump.

The pistons have a muffled knock, caused by the pistons beating against the cylinders. Can be heard at low crankshaft speed and under load

- Unacceptable increase in clearance between pistons and cylinders.

Replace pistons and, if necessary, cylinder liners.

- Severe wear of piston ring ends and corresponding grooves on the piston.

Replace piston rings and, if necessary, pistons.

A double, metallic, sharp knock of piston pins is caused by a large clearance. Better heard when the engine is idling

- Unacceptable increase in the clearance between the pin and the bushing of the upper head of the connecting rod.

Replace the pin and, if necessary, the connecting rod.

Increased temperature of the liquid in the cooling system

- Weak tension or breakage of the water pump drive belts.

Tighten or replace the belts.

- Malfunction of thermostats

Replace thermostats.

- Contamination of the radiator core.

Clean dirt from the radiator core.

Increased coolant consumption

- Damage to the radiator

Repair the damage or replace the radiator

- Liquid leak through the mechanical seal of the water pump.

Replace the mechanical seal.

- Coolant entering the lubrication system through the rubber sealing rings of the cylinder liners or through the rubber gaskets of the cylinder heads.

Replace the sealing rings of the cylinder liners or rubber gaskets.

* Before looking for the cause of the malfunction in the lubrication system and the cooling system, you need to make sure that the oil pressure and temperature indicators are in good working order.

Electric torch device (ETD)

The EDT spark plug is faulty, the 30A fuse is burning

- Short circuit in the thermal relay coil or electrical wires

If the spark plugs are in good working order, disconnect the wire from the thermal relay that connects it to the EDT power button.

No short circuit when the EDT is turned on again indicates short circuit of the thermal relay coil.

In this case, the thermal relay should be replaced.

If the thermal relay coil is intact (determined by touch) and a short circuit occurs with the wires disconnected from the spark plugs, this indicates a short circuit in the electrical wires. Eliminate the short circuit.

- Short circuit of the spark plug to ground

Disconnect the wire from the terminal of the left spark plug, eliminating contact of the tip with ground, and turn on the EFU again. If there is a short circuit, disconnect the wire from the terminal of the right spark plug.

No short circuit indicates a short circuit in the right spark plug. Replace the failed spark plug.

After eliminating the short circuit, it is recommended to check the condition of the insulation of the electrical wires, the operability of the thermal relay and the EFU switching relay, and if the short circuit occurred when starting the engine, the operability of the shunt relay

The EFU does not work, voltage does not reach the EFU

- Burnout of the thermal relay coil

Turn on the EFU and check the voltage at the terminals of the thermal relay. The absence of voltage at the terminal on the side of the plug connection with voltage at the other terminal indicates a burnout of the coil. Replace the thermal relay.

- Burnout of spark plugs or lack of contact in the circuit

Turn on the EFU and check if there is voltage at the terminals of each EFU product, starting with the torch spark plugs. The presence of voltage at the right spark plug output indicates that the spark plugs have burned out. Replace the spark plugs or restore contact.

- One of the spark plugs has burned out

Turn on the EFU for 10-15 sec, then replace the cold spark plug.

No spark plug flame

- No fuel supply to the spark plug

Loosen the fuel supply nipple on the spark plug. Turn on the EFU and after the indicator lights up (the electromagnetic valve opens), turn the crankshaft with the starter.

If fuel does not leak through the loosely screwed threaded connection of the nipple when the valve is open, eliminate the malfunction in the fuel supply system.

- No fuel flow through the spark plug

Unscrew the spark plug from the manifold. Wash and blow out the jet, fuel filter and fuel supply cavities with compressed air. Check for the presence of a torch flame, for which:

- - connect the fuel pipe and electrical wires to the spark plug;

- - ensure a reliable connection of the spark plug body to ground and make sure that the terminal is isolated from ground;

- - turn on the EFU and turn the crankshaft using the starter.

If there is no flame, replace the faulty spark plug.

Electrical equipment

The charging circuit indicator lamp lights up at the rated engine crankshaft speed

- Loose tension of the alternator drive belts

Adjust the belt tension

- Contamination of the contact rings

Wipe the rings with a cotton napkin moistened with clean gasoline. If contamination is not removed, clean with glass paper and wipe again with a napkin

- Wear or sticking of brushes in brush holders

Check the height of the brushes, their free movement in the channels of the brush holder and the force of the springs; if necessary, replace the brush holder or brushes

- Rectifier unit breakdown

Replace the unit

- Stator winding short circuit

Replace the stator assembly

- Excitation circuit fault

Check the excitation circuit for serviceability

- Bearing parts worn or damaged

Replace the generator

- Generator fan deformation

Straighten bent areas

Bearing overheating

- Excessive belt tension

Adjust belt tension

Excessively rapid wear of generator brushes

- Contamination of contact surfaces rings

Wipe the rings with a cotton cloth soaked in clean gasoline. If necessary, clean with glass sandpaper and wipe again with a cloth

- Radial runout of contact rings

Check the radial runout of the rings. If necessary, grind the slip rings

Excessively high charging current

- Short circuit in the generator brush assembly or in the circuit between the generator and the regulator

Repair the short circuit

- Malfunction of the voltage regulator

Replace the regulator

- Malfunction of the generator excitation winding disconnect relay

Replace the relay

Increased noise level during generator operation

- Loose pulley fastening

Tighten the nut

- No contact between the brushes and the commutator

Wipe the commutator with a clean rag soaked in gasoline, or clean it. Clean the brushes or replace them with new ones.

Check the condition of the brush springs and replace them if faulty. Check for sticking brushes in brush holders

Starter

Starter does not work

- Short circuit or open circuit in pull-in winding of traction relay

Replace relay

- Open or no contact in power supply circuit

Find damage location and restore contact

- Sticking brushes

Remove brush holder, take out brushes and remove brush dust

- Starter relay failure (738.3747-20)

Replace relay

- Open circuit inside starter

Check and eliminate starter defects or replace starter

Engine crankshaft does not turn with starter (traction relay trips)

- Discharged batteries

Charge batteries

- Violation of the battery charging circuit

Repair the malfunction

- Malfunction of the voltage regulator

Replace the regulator

- Oiling or contamination of the brush-collector unit

Clean the collector and brushes from oil, dirt, copper-graphite dust

- Poor contact of the starter housing with the ground of the power plant

Ensure a reliable connection

- Use of oil that is not suitable for the season

Change the oil

After starting the engine, the anchor continues to rotate

- Malfunction of the traction relay

Replace the relay

- Welding of the starter relay contacts (738.3747-20)

Replace the relay

When the starter is turned on, the traction relay does not operate (there is no characteristic click)

- Discharged battery

Charge the battery

- Break in the pull-in winding of the traction relay

Replace the relay

- Malfunction of the instrument switch and starter

Replace switch

- Open or short circuit in starter relay winding (738.3747-20)

Replace relay

Starter anchor rotates but does not turn crankshaft

- Broken flywheel ring gear or toothed wheel

Replace flywheel ring gear or toothed wheel

- Starter adjustment error

Adjust starter

- Drive malfunction

Replace drive

When starter is turned on, repeated clicks of traction relay and impacts of drive toothed wheel on flywheel ring gear are heard

- Unreliable contact of starter traction relay circuit

Check contact connections and fix malfunction

- Malfunction of the holding winding of the traction relay

Replace the traction relay

- Malfunction of the winding or contact connection of the starter relay (738.3747-20).

Replace the relay

When the starter is turned on, noise (grinding) is heard from the drive gear

- Installation of the starter with a skew

Install the starter correctly

- Incorrect adjustment of the closing moment of the traction relay contacts

Adjust the gap between the gear and the thrust washer when the starter is turned on

The drive gear systematically does not engage with the flywheel ring during normal operation of the relay

- The presence of burrs on the ends of the flywheel teeth or drive gear

File and clean burrs on flywheel ring gear teeth or drive gear

- Wear on flywheel ring gear or drive gear tooth ends

Replace flywheel ring gear or drive gear