The fuel supply system filters the fuel and distributes it evenly among the engine cylinders in metered portions at strictly defined moments

The engine uses a split-type fuel supply system consisting of a fuel tank, low-pressure fuel lines, coarse and fine fuel filters, fuel priming and fuel pumps, a high-pressure fuel pump (HPFP) with a stop solenoid, high-pressure fuel lines, injectors, an electromagnetic valve, and pin plugs of the electric torch device (ETD).

The fuel tank, coarse fuel filter, and fuel priming pump must be installed on the product on which the engine is used; all other elements of the fuel supply system are installed directly on the engine.

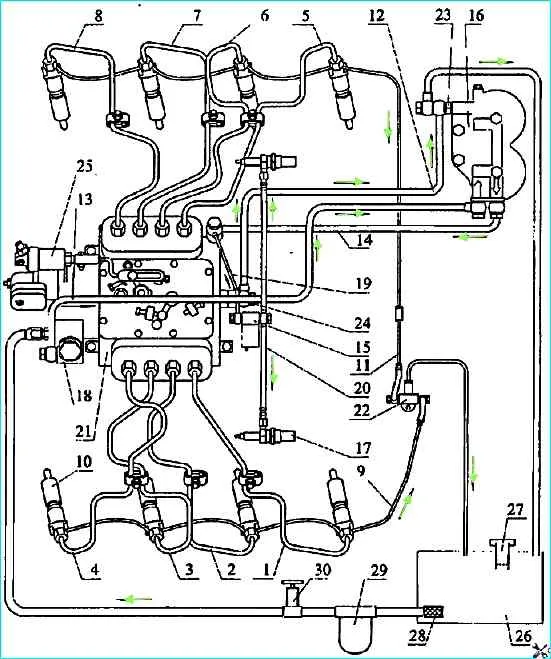

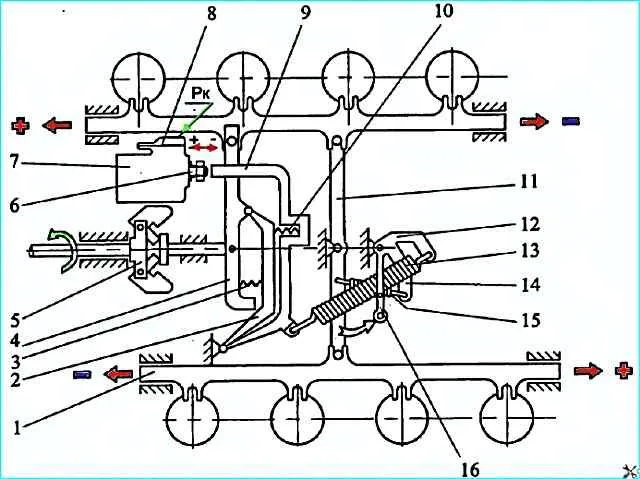

Engine fuel supply system: 1-8 high-pressure fuel lines; 9 fuel drain pipe of left cylinder head injectors; 10 injector; 11 - fuel drain pipe of right cylinder head injectors; 12 fuel outlet pipe of high-pressure fuel pump; 13 fuel outlet pipe; 14 fuel supply pipe of high-pressure fuel pump; 15 electromagnetic valve of electric fuel unit; 16 fine fuel filter; 17 - spark plug of electric fuel unit; 18 fuel priming pump; 19 fuel pipe to electromagnetic valve; 20 fuel pipe from electromagnetic valve to spark plugs of electric fuel unit; 21 high-pressure fuel pump; 22 Tee; 23 Valve; 24 High-pressure fuel pump bypass valve; 25 Pneumatic engine stop cylinder; 26 Fuel tank; 27 Filler neck with mesh filter; 28 Fuel intake tube with mesh filter; 29 coarse fuel filter: 30 - fuel priming pump

The diagram of the engine fuel supply system is shown in Figure 1.

Fuel from the fuel tank 26 through the coarse filter 29 and the fuel priming pump 30 is fed by the fuel priming pump 18, through the fuel pipe 13 to the fine filter 16.

From the fine filter, through the low-pressure fuel pipe 14, the fuel enters the high-pressure fuel pump 21, which, in accordance with the order of operation of the cylinders, distributes the fuel through the high-pressure fuel lines 1-8 to the injectors 10.

The injectors inject fuel into the combustion chambers.

Excess fuel, and along with it the air that has entered the system, is discharged through the bypass valve 24 and valve 23 into the fuel tank.

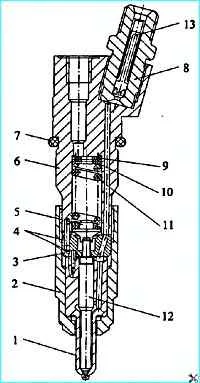

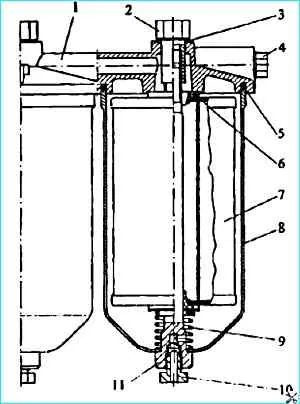

Injector: 1 - nozzle body; 2 - nozzle nut; 3 - spacer; 4 - pins; 5 - nozzle rod; 6 - nozzle body; 7 - sealing ring; 8 - nozzle nipple; 9, 10 - adjusting washers; 11 - nozzle spring; 12 - nozzle needle; 13 - slot filter

Type 273 nozzle of closed design, with five spray holes and hydraulic control of the nozzle needle lift is shown in Figure 2.

All nozzle parts are assembled in housing 6. The nozzle housing 1, inside which the needle 12 is located, is pressed to the lower highlander of the nozzle housing by nut 2 through spacer 3.

The housing and the nozzle needle form a precision pair.

The angular fixation of the nozzle housing relative to the spacer and the spacer relative to the nozzle housing is carried out by pins 4.

The spring 11 exerts pressure on the upper end of the nozzle needle through rod 5.

The necessary tension of this spring is achieved by a set of adjusting washers 9, 10, installed between the spring and end of the internal cavity of the injector body.

Fuel is supplied to the injector under high pressure through the nipple 8 with a slotted filter 13 built into it, then through the channels of the body 6, spacer 3 and the body of the sprayer 1 - into the cavity between the body of the sprayer and the needle 12 and, lifting it, is injected into the engine cylinder.

The fuel that has leaked through the gap between the needle and the body of the sprayer is discharged through the channels in the body of the sprayer and drains into the tank through the drain pipes 9 and 11 shown in Figure 42.

The injector is installed in the cylinder head, fixed with clamps, which are secured with a nut.

The end of the sprayer nut is sealed from gas breakthrough by a corrugated copper gasket.

The sealing ring 7 (Figure 2) prevents the ingress of dust and liquids cavity between the injector and the cylinder head.

Checking and adjusting the injectors, as well as replacing the sprayers, must be carried out in a specialized workshop.

It is prohibited to install injectors of other models, except those specified in the instructions, due to the possibility of engine failure.

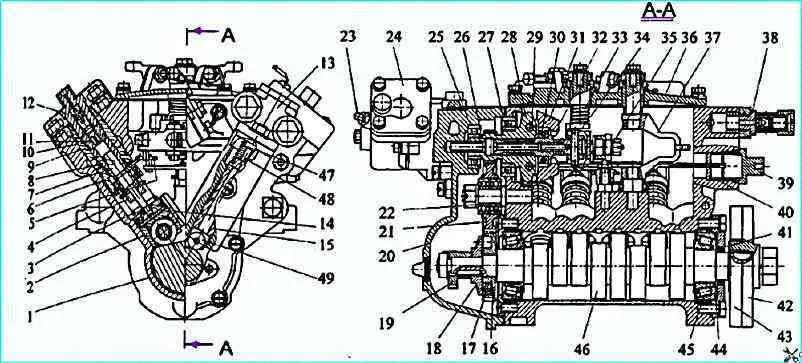

High-pressure fuel pump (HPFP 337-20) with fuel priming pump: 1 HPFP body; 2 Pusher; 3 - Pusher spring; 4 Rotary sleeve; 5 Rack; 6 HPFP section body; 7 Plunger; 8 Plunger sleeve; 9 - Sealing ring; 10 Discharge valve seat; 11 Discharge valve; 12 Fitting; 13 Fuel priming pump; 14 - Cracker; 15 Pusher; 16 Governor drive gear; 17 Drive gear cracker; 18 Drive gear flange; 19 Eccentric of fuel priming pump: 20 Rear regulator cover; 21 Intermediate regulator cover; 22 Intermediate governor gear bearing; 23 Fuel delivery cycle adjustment screw; 24 Fuel delivery corrector according to boost air pressure; 25 Governor cover bearing; 26,44 Adjusting linings; 27 Weight holder bearing; 28 Weight holder; 29 Weight axis; 30 Governor coupling thrust bearing; 31 Weight; 32 Governor coupling; 33 Stop lever return spring; 34 Pin; 35 Straight corrector; 36 Upper governor cover; 37 Governor spring lever; 38 - Bypass valve; 39 - Rack plug; 40 Rack bushing; 41 Sleeve; 42 Flange of driven half coupling; 43 driven half coupling; 45 camshaft bearing; 46 camshaft; 47 piston rod bushing; 48 push rod; 49 roller

The high-pressure fuel pump (Figure 3) is designed to supply strictly dosed portions of fuel under high pressure to the engine cylinders at certain moments.

The car engine is equipped with a fuel injection pump model 337-20 with an all-mode regulator.

The bus engine is equipped with a fuel injection pump model 337-71 with a two-mode regulator.

The fuel injection pump plunger diameter is 11 mm, the plunger stroke is 13 mm, the discharge valve is a mushroom, feather-shaped with a diameter of 7 mm without unloading.

Eight sections are installed in the fuel injection pump body 1, consisting of a body 6, a plunger sleeve 8, a plunger 7, a rotary sleeve 4, a discharge valve 11 with seat 10, pressed to the plunger sleeve by nipple 12.

The plunger makes a reciprocating motion under the action of the cam shaft 46 and the spring 3 of the pusher. The pusher 2 is fixed from turning in the housing by cracker 14.

The cam shaft rotates in roller bearings 45.

The outer races of the bearings are installed in steel rings pressed into the pump housing. The cam shaft is fixed from axial movement by covers.

The tension of the cam shaft bearings is adjusted by gaskets 44 and should be 0.05-0.15 mm.

To change the fuel supply, plunger 7 is rotated by means of sleeve 4, connected through the axis of the driver to the rack 5 of the pump. The rack moves in guide bushings 40.

The holes for the guide bushings in the fuel injection pump housing on the drive side are closed with plugs 39.

On the opposite side of the pump, on the rear cover 20 of the regulator, there is a fuel supply corrector for the boost air pressure 24.

At the front end of the housing, where the fuel exits the pump, a bypass valve 38 is installed, which ensures the pressure before the inlet ports of the plungers in operating modes of 0.13-0.19 MPa (1.3-1.9 kgf/cm 2).

The pump is lubricated by circulation, under pressure from the general lubrication system of the engine.

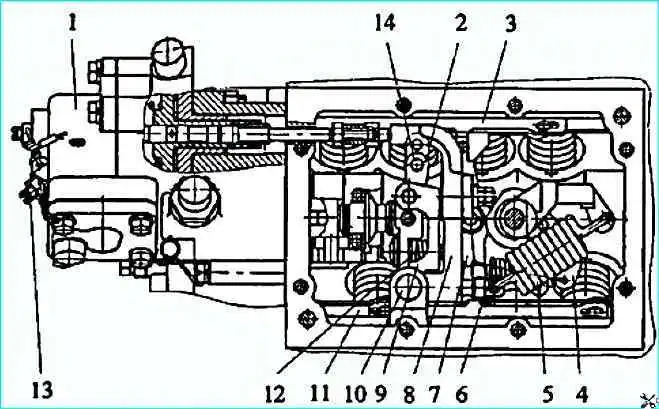

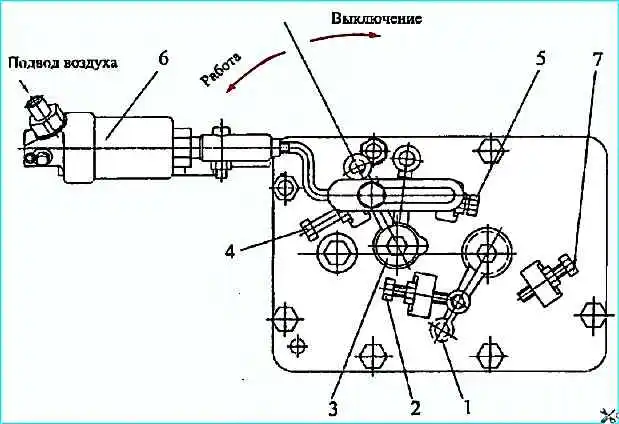

Injection pump regulator (top view): І fuel supply corrector by boost air pressure; 2 - rack lever; 3, 11 racks; 4 - starter spring lever; 5 main regulator spring; 6 starter spring; 7 rack lever; 8 - regulator lever; 9 - weight clutch lever; 10 axle; 12 reverse corrector; 13 fuel supply cyclic adjustment screw; 14 - pin

Injection pump speed regulator mod. 337-20 (Figure 4) all-mode, direct-acting, changes the amount of fuel supplied to the cylinders depending on the load, maintaining a given crankshaft speed.

The regulator is installed in the camber of the fuel injection pump housing. The drive gear of the regulator 16 (Figure 3) is mounted on the camshaft of the pump, the rotation of which is transmitted through rubber crackers 17.

The driven gear is made integral with the holder 28 of the weights, rotating on two ball bearings.

When the holder rotates, the weights 31, swinging on the axes 29, diverge under the action of centrifugal forces and through the thrust bearing 30 move the clutch 32 of the regulator, which, resting against the finger 34, in turn moves the levers 2, 8 and 9 of the regulator (Figure 4), overcoming the force of the spring 5.

The lever 2 is connected via a pin to the right rack 3 of the fuel pump. The right rack is connected to the left rack 11 via rack lever 7.

Scheme of operation of the speed governor: 1 fuel injection pump rack; 2 - weight clutch lever; 3 - reverse corrector spring; 4 - rack lever; 5 weight holder; 6 - fuel supply adjusting bolt; 7 fuel supply corrector according to boost fuel pressure; 8 membrane; 9 governor lever; 10 direct corrector spring; 11 rack lever; 12 spring lever; 13 governor spring; 14 - starting spring lever; 15 starting spring; 16 governor control lever

The operation diagram of the speed governor is shown in Figure 5.

Governor control lever 16 is rigidly connected to lever 12. Governor spring 13 is connected to lever 12, and starting spring 15 is connected to levers 14 and 11.

During governor operation, the centrifugal forces of the weights are balanced by the force of spring 13.

As the crankshaft speed increases, the weights, overcoming the resistance of spring 13, move levers 2, 4 and 9, and with them the fuel injection pump rack - the fuel supply decreases.

As the crankshaft speed decreases, the centrifugal force of the weights decreases, and the levers with the fuel injection pump rack, under the action of the spring force, move in the opposite direction - fuel supply and speed crankshaft rotation speed increases.

When the regulator lever 9 rests on the bolt 6 and the crankshaft rotation speed is less than 1800 min-1 -1, the spring 10 of the direct corrector moves the pump racks (via levers 2 and 4) in

the direction of increasing the fuel supply, providing the required value of the maximum engine torque.

At a rotation speed of less than 1400 min-1 -1, the spring 3 of the reverse corrector moves the lever 4 with the racks in the direction of decreasing the fuel supply, limiting the maximum smoke of the engine exhaust gases.

Tension fuel pump regulator cover: 1 regulator control lever; 2 - minimum speed limiting bolt; 3 engine stop lever; 4 - starting feed adjustment bolt; 5 stop lever travel limiting bolt; 6 - pneumatic engine stop cylinder; 7 - maximum speed limiting bolt

The fuel supply is stopped by turning the lever 3 (Figure 6) of the engine stop until it stops against the bolt 5.

The lever is turned by the force of the spring built into the engine stop solenoid 6 when the holding winding of the solenoid is disconnected from the power source (the key of the instrument and starter switch lock is in the fixed position "0").

In this case, lever 3, having overcome the forces of springs 33 (Figure 3) and 5 (Figure 4), through pin 14 will turn levers 2.9 and 8, the racks will move until the fuel supply is completely stopped

When the key of the instrument and starter switch lock is turned to the fixed position "I", power is supplied to the holding winding of the stop solenoid, and when the key is further turned to the non-fixed position "II", power is also supplied to the retractor winding of the electromagnet, the electromagnet rod, overcoming the force of its own spring, extends and releases lever 3 (Figure 6).

Lever 3, under the action of spring 33 (Figure 3), returns to the working position, and starting spring 6 (Figure 4) through rack lever 7 returns the fuel injection pump racks to the position corresponding to the maximum fuel supply required to start the engine.

When the instrument and starter switch key is moved from the non-fixed position "II" to the fixed position "I", the retractor winding of the electromagnet is disconnected from the power source and the stop electromagnet rod remains in the working position only due to the holding winding.

Checking and adjusting the fuel injection pump, as well as replacing plunger pairs, sealing rings of the fuel injection pump sections must be carried out in a specialized workshop by a qualified specialist.

It is prohibited to install for engine 740.30-260 high-pressure fuel pump of other models in order to avoid deterioration of the engine operating quality, increased toxicity and smoke of exhaust gases, as well as engine failure!

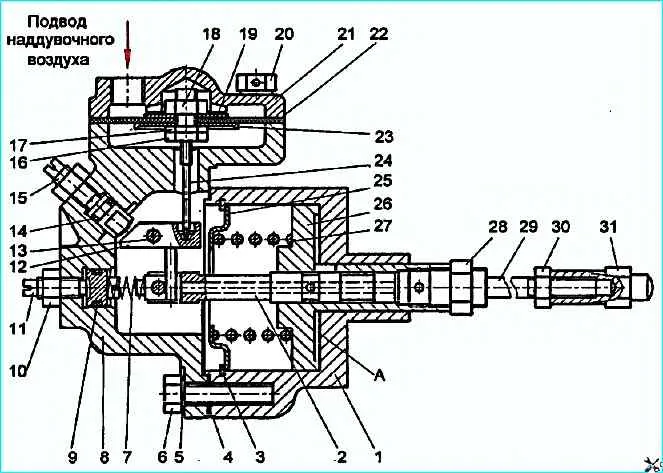

Fuel supply corrector by boost air pressure: 1 corrector housing; 2 corrector spool; 3 thrust ring; 4 - membrane housing gasket; 5 - washer; 6 bolt; 7 corrector spring; 8 - membrane housing; 9 - sealing ring; 10 nut; 11 adjusting screw; 12 - corrector lever; 13 lever axis; 14 adjusting; 16 nut; 17 sealing ring; 15 - screw rod bushing; 18 - nut; 19 washer; 20 bolt; 21 - membrane cover; 22 membrane; 23 plate; 24 membrane rod; 25 - platesprings; 26 corrector piston; 27 piston spring; 28 nut; 29 - stud; 30 nut; 31 stud tip

Boost air pressure fuel supply corrector (Figure 7).

Boost air pressure corrector reduces fuel supply when boost air pressure drops below 40-45 kPa (0.4-0.45 kgf/cm 2), thereby providing thermal protection for the engine and limiting exhaust smoke.

Piston 26 with spool 2 is installed in corrector body 1. Spring 27, fixed by plate 25 and ring 3, acts on the piston.

Stud 29 with tip 31, which is a nominal stop in regulator.

The tip is secured with a nut 30. A spring 7 acts on the spool 2, the pre-tension of which can be changed by the adjusting screw 11.

The membrane housing 8 is attached to the corrector housing 1 through the gasket 4. The membrane unit with the rod is installed in it (parts 24,16,17,23,22, 19, 18).

The membrane is clamped between the housing 8 and the cover 21. The corrector lever 12 is installed in the membrane housing 8 on the axis of the lever 13, the rotation of which is limited by the adjusting screw 15.

Indirect-acting fuel supply corrector; when the boost air pressure in the membrane cavity changes, the position of the spool changes, which in turn determines the position of the corrector piston.

Oil under pressure from the engine lubrication system is supplied to cavity "A" between the corrector body 1 and piston 26 through a threaded hole and a 0.7 mm nozzle in the corrector body (not shown in the figure).

Under the action of this pressure, the piston, compressing spring 27, moves to the left until the windows in the piston and spool open and the oil goes to drain.

In this case, a constant oil flow through the corrector is established.

When the position of the spool changes, the piston moves after it (tracking system).

Air from the engine intake manifold is supplied to the membrane cavity through the threaded hole in cover 21.

When the air pressure drops below 0.04 MPa (0.4 kgf/cm 2) the force of the corrector spring 7 acting on the spool becomes greater than the force created by the pressure of the boost air on the membrane and transmitted through the membrane rod and the corrector lever also to the spool.

The spool moves to the right until the forces acting on it are in equilibrium.

Following the spool, the piston with the pin 29 and the tip 31 moves to the right, moving the regulator lever 8 resting against it to the right (Figure 4).

Following the regulator lever, under the action of the centrifugal forces of the weights, levers 9.2 and 7 with the pump racks move towards decreasing the fuel supply.

Corrector adjustment

The corrector has two external adjustments - screws 11 and 15 (Figure 7).

Screw 11 changes the pre-tension of the corrector spring 7, thereby changing the start of the corrector operation.

If it is necessary to increase the value of the boost air pressure at which the corrector starts to operate, screw 11 is tightened, increasing the pre-tension of the spring 7.

Screw 15 regulates the nominal cyclic fuel supply. When screw 15 is turned out, the fuel supply increases.

If it becomes necessary to remove the corrector, it is first necessary to measure the protrusion of the tip of stud 31 relative to the rear end of the fuel injection pump housing, and after installing the corrector in place, restore the size of this protrusion and lock the tip with nut 30.

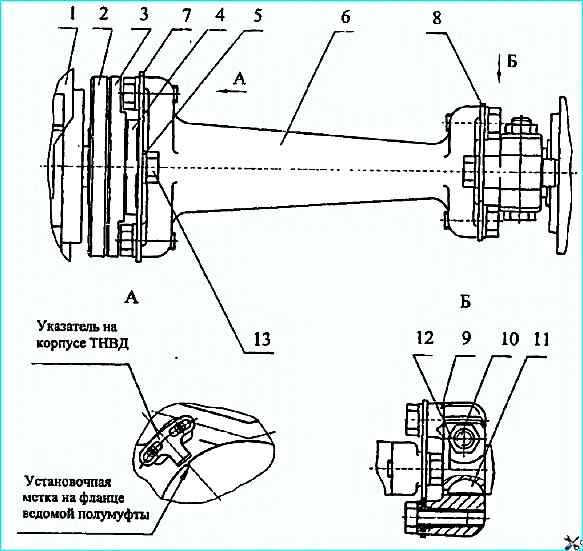

Fuel injection pump drive: 1 fuel injection pump housing; 2 driven half coupling; 3 flange of driven half coupling; 4 centering flange; 5 - centering sleeve; 6 drive shaft; 7, 8 - pack of compensating plates; 9 - leading half coupling; 10 tie bolt; 11 key; 12 - nut; 13 bolt of the driven half coupling

The fuel injection pump drive is shown in Figure 8.

It consists of the fuel injection pump drive shaft 6 with packs of front 7 and rear8 compensating plates, the driven half coupling 2, the flange of the driven half coupling 3, the centering flange 4, the driving half coupling 9 and the centering bushings 5.

Each pack of compensating plates consists of 5 plates, each 0.5 mm thick.

All bolts in the fuel injection pump drive must be of strength class R100 and tightened to a torque of 65-75 Nm (6.5-7.5 kgf m).

The tightening of all bolts must be checked with a torque wrench. Before installing the bolts, check for the presence of centering bushings.

Deformation (bending) of the front and rear compensating plates is not allowed.

Tie bolt 10 of the leading half coupling should be tightened last.

Fine fuel filter: 1 cover; 2 - bolt; 3 - sealing washer; 4 - plug; 5, 6 - gaskets; 7 filter element; 8 - cap; 9 - filter element spring; 10 drain plug; 11 rod

Fine fuel filter is shown in Figure 9. It is designed for final cleaning of fuel from small particles before entering the high-pressure fuel pump.

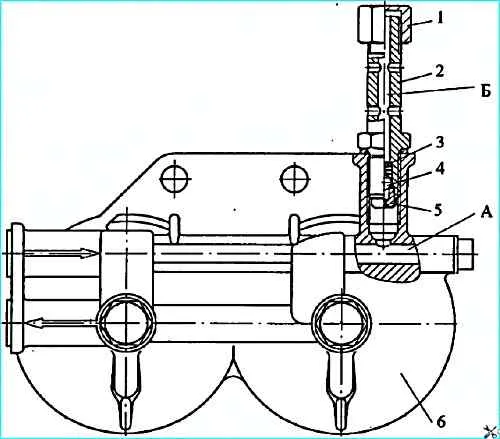

Valve: 1 - nut; 2 - valve body; 3 spring; 4 ball; 5 - jet; 6 - fuel fine filter cover

The filter is installed at the highest point of the fuel supply system to collect and remove air into the tank along with some of the fuel through the valve (Figure 10) installed on the bypass from the filter,

When replacing filter elements, it is necessary to strictly follow the rules for servicing the fuel supply system.

Do not allow contaminants to enter the system and use filter elements only of the following models 740.1117040-01, 740.1117040-02, 740.1117040-04.

The valve is shown in Figure 10.

When the pressure in the fuel supply cavity "A" reaches 25...45 kPa (0.25-0.45 kgf/cm 2), ball 4 moves and flow fuel from cavity "A" to cavity "B" through valve jet 5.

At a pressure of 200-240 kPa (2-2.4 kgf/cm 2), the valve is fully opened and fuel is bypassed into the fuel tank through cavity "B".

The piston-type fuel pump 13 (Figure 3) is designed to supply fuel from the tank through coarse and fine filters and the fuel priming pump to the inlet cavity of the high-pressure fuel pump.

The pump is installed on the rear cover of the regulator, its drive is carried out from the eccentric 19, located on the rear end of the camshaft of the high-pressure fuel pump.

The piston, piston spring, rod bushing 47 and pusher rod 48, inlet and discharge valves with springs.

Eccentric 19 via roller 49, pusher 15 and rod 48 imparts reciprocating motion to the piston of the fuel priming pump.

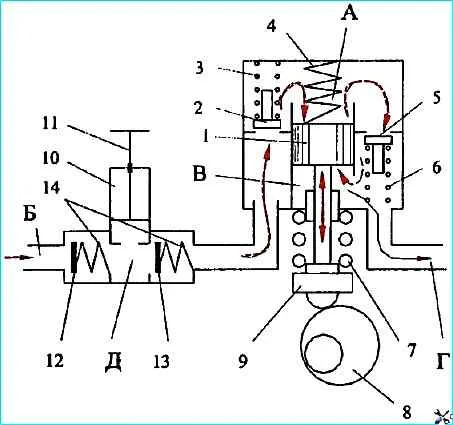

Fuel priming and fuel pump operation diagram: 1 - piston; 2 - inlet valve; 3, 6 valve springs; 4 - piston spring; 5 discharge valve; 7 - pusher spring; 8 eccentric; 9 pusher; 10 - fuel priming pump; 11 piston; 12 - inlet valve; 13 discharge valve; 14 - springs

The pump operation diagram is shown in Figure 11.

When the pusher 9 is lowered, the piston 1 moves downwards under the action of the spring 4.

A vacuum is created in the cavity "A" and the inlet valve 2, compressing the spring 3, allows fuel to flow into the cavity "A".

At the same time, the fuel located in the discharge cavity "B" is forced out into the line "G", while the valve 5, under the action of the spring 6, closes, preventing the fuel from flowing from the cavity "B" to the cavity "A".

When the piston 1 moves upward, the fuel filling the cavity "A" through the discharge valve 5 enters the cavity "B" under the piston, while the inlet valve closes.

When the pressure increases in the discharge line, the piston does not make a full stroke following the pusher, but remains in a position determined by the balance of the fuel pressure force on one side and the spring force on the other.

The piston-type fuel pump 10 (Figure 11) serves to fill the fuel system with fuel before starting the engine and remove air from it.

The pump consists of a housing, a piston, a cylinder, an inlet and a discharge valve.

The fuel system should be pumped using the pump piston, having first unlocked it by turning it counterclockwise.

When piston 11 moves upward, a vacuum is created in the space below it.

Inlet valve 12, compressing spring 14, opens, and fuel enters cavity "D" of the pump.

When the piston moves downward, the inlet valve closes and the discharge valve 13 opens, fuel under pressure enters the discharge line, ensuring the removal of air from the engine fuel system through the FTOT valve and the injection pump bypass valve.

After bleeding the system, it is necessary to lower the piston and fix it by turning it clockwise.

In this case, the piston will be pressed against the end of the cylinder through the rubber gasket, sealing the suction cavity of the fuel priming pump.

It is not allowed to start the engine with an unfixed piston due to the possibility air suction through the piston seal.

Fuel lines are divided into low-pressure fuel lines - 0.4-2 MPa (4-20 kgf/cm 2) and high-pressure fuel lines over 20 MPa (200 kgf/cm 2).

Low-pressure fuel lines are made of 10 mm steel pipes with soldered tips.

High-pressure fuel lines of equal length (1=595 mm) are made of steel pipes with an internal diameter of 2+0.05 mm by upsetting the ends of connecting cones with compression washers and union nuts for connection to the fuel injection pump and injector nozzles.

To avoid breakage from vibration, the fuel lines are secured with clamps to the intake manifolds