Design features

Cooling system - liquid, closed type, with forced circulation

The pump provides a constant flow of fluid through the cooling jacket of the block and cylinder head, after which the fluid passes through the thermostat and radiator, releasing heat to the surrounding air.

The cooling jacket, pump, thermostat and radiator form a “large circle” of circulation

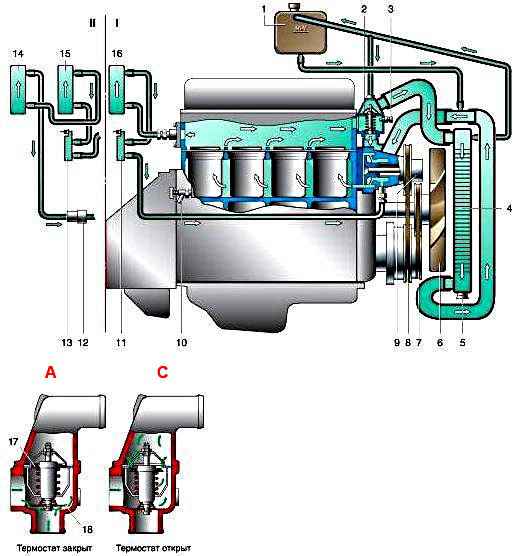

ZMZ-402 and UMZ-4215 engine cooling system: 1 - with one heater; II - with two heaters and an electric pump (for vans with two rows of seats and buses); 1 - expansion tank; 2 - thermostat; 3 - coolant temperature indicator sensor; 4 - radiator; 5 - radiator drain plug (tap); 6 - fan; 7 - fan drive belt; 8 - coolant pump drive belt; 9 - coolant pump; 10 - drain valve of the cylinder block; 12 - electric pump of the heating system; 11.13 - heater tap; 14 - additional heater radiator; 15, 16 - main heater radiator; 17 - main thermostat valve; 18 - bypass valve; A - the thermostat is closed; C - thermostat open

The cooling system includes a cab heater core, an auxiliary heater core (for vans with two rows of seats and buses), and an electric pump mounted on the heating system outlet hose (for cars with two rows of seats and buses).

The amount of liquid passing through the heater radiator does not depend on the thermostat and is regulated only by the heater tap.

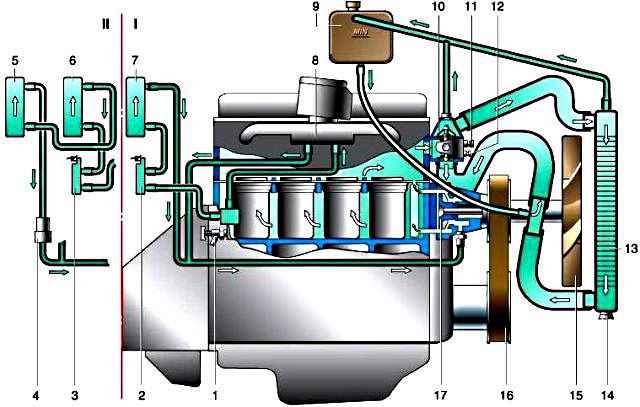

The ZMZ-406 engine cooling system is basically similar to the ZMZ-402 engine cooling system, but has differences in that the intake pipe is heated.

In addition, an engine temperature sensor and an emergency coolant temperature sensor are additionally installed on the thermostat housing.

ZMZ-406 engine cooling system: 1 - heating system with one heater; II - heating system with two heaters; 1 - drain valve of the cooling system; 2, 3 - heater taps; 4 - electric pump of the heating system; 5 - additional heater radiator; 6, 7 - heater radiators; 8 - intake pipe heating unit; 9 - expansion tank; 10 - thermostat; 11 - coolant temperature indicator sensor; 12 - emergency coolant temperature sensor; 13 - radiator; 14 - radiator drain plug; 15 - fan; 16 - poly V-belt for fan and pump drive; 17 - coolant pump

The coolant pump is of a centrifugal type, located in the front part of the cylinder block, driven from the crankshaft pulley by a poly-V or V-belt (for ZMZ-402 and UMZ-4215).

The redistribution of liquid flows is controlled by a thermostat with two valves: main and bypass.

On a cold engine, the main valve is closed, and all the liquid circulates in a “small circle”, returning directly to the cooling jacket, bypassing the radiator. This speeds up warming up of a cold engine.

At a temperature of 80–84°C (78–82°C for ZMZ-402 and UMZ-4215), the main valve begins to open, allowing part of the liquid to pass through a large circle, and the bypass valve closes.

At a temperature of 94°C, the main valve opens completely, and the bypass valve closes and all the liquid circulates through the engine radiator.

Fan - with a six-bladed plastic impeller. Driven by a V-belt or poly-V-belt (for ZMZ-406) from the crankshaft.

The fan axis of the ZMZ-402 rotates in two bearings.

For UMZ-4215 engines, the fan has a bearing, the same as the pump. The bearings are installed in a special bracket, secured to the timing gear cover with three pins.

In ZMZ-406 the fan impeller is installed on the coolant pump pulley.

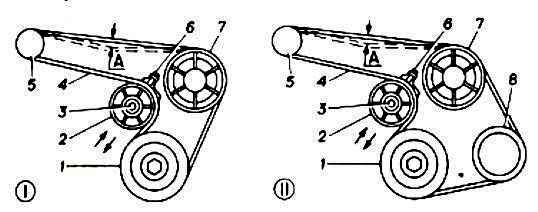

The UMP engine fan drive has a tension pulley on a separate bracket.

The radiator is a tubular-tape type, with side plastic tanks.

The tanks are connected to the radiator frame through a rubber sealing gasket by crimping the support plate onto the tank flange.

On the tanks and the top plate of the radiator frame there are brackets for attaching the radiator to the body.

On the left side of the car in the lower part there is a plug or tap for draining the coolant.

Diagram for tensioning the drive belt: 1 - for vehicles without power steering; II - for cars with power steering; 1 - crankshaft pulley; 2 - tension roller; 3 - tension roller mounting bolt; 4 - belt; 5 - generator pulley; 6 - bolt for moving the tension roller; 7 - water pump pulley; 8 - power steering pump pulley (for cars with power steering)

Expansion tank - plastic, connected by a hose to the pipe of the lower radiator tank, a tube to the thermostat pipe and to the left radiator tank.

There is a MIN mark on the tank, indicating the lower permissible level of coolant in the tank. The expansion tank is closed with a screw plug.

The tightness of the system is ensured by a valve in the expansion tank plug, which maintains excess pressure in the system on a hot engine (due to this, the boiling point of the liquid increases to 115°C and its losses due to evaporation are reduced).

The valve opens when the pressure in the system decreases (on a cooling engine).

On the ZMZ-406 engine, on the left side, and on the UMZ and ZMZ-402 engines, on the right side there is a valve for draining coolant from the cylinder block.