The power unit, depending on the model and configuration, can be equipped with a gearbox of several models and different configurations

Gearboxes manufactured by OAO YaMZ (indicated by the letter ″B″ in the marking) are equipped with an aluminum alloy demultiplier housing, a rod support (between the cylinder and the demultiplier housing) of the demultiplier switching mechanism with a changed location of the demultiplier signal lamp switch.

Proper operation of the gearbox and its service life are directly dependent on the culture of operation, therefore, it is necessary to carefully consider the implementation of all routine maintenance provided for in this manual.

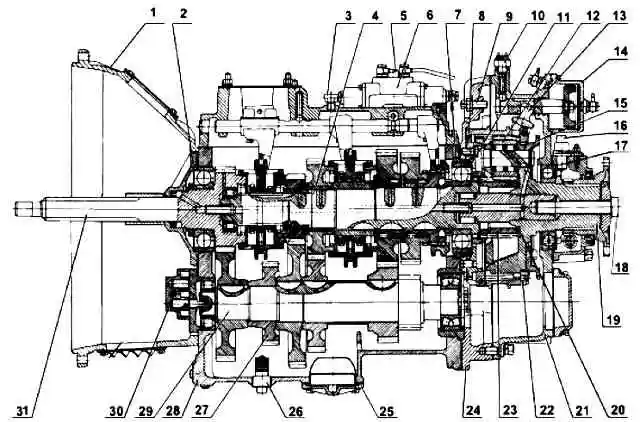

YaMZ-238VM gearbox: 1 - clutch housing; 2 - shims adjusting the input shaft; 3 - crankcase breather; 4 - secondary shaft; 5 - air distributor breather; 6 - air distributor; 7 - centering ring; 8 - low range clutch; 9 - bolt for adjusting the stop of the switch rod of the demultiplier with a lock nut; 10 - switch of the signaling device for switching the demultiplier; 11 - shims adjusting the secondary shaft; 12 - satellites; 13 - switch fork of the demultiplier; 14 - cylinder for switching the demultiplier; 15 - high range clutch; 16 - speed sensor of the low range blocking system; 17 - shims of the output shaft; 18 - mounting bolt in the output shaft flange. 19 - output shaft; 20 - thrust ring of the sun gear; 21 - crankcase demultiplier; 22 - ring gear; 23 - sun gear; 24 - spacer; 25 - pump intake cover with mesh; 26 - drain plug with magnet; 27 - power take-off gear; 28 - crankcase of the main box; 29 - intermediate shaft; 30 - oil pump; 31 - primary shaft

The use of lubricants other than those specified in this manual is not permitted.

In order to avoid damage to the range synchronizer and the main gearbox synchronizers, shifting gears in the main box with the range switch indicator lamp on is not allowed.

In order to avoid an excessive increase in the engine speed and increased wear of the gearbox synchronizers, it is not allowed to turn on the lower range in the demultiplier at a vehicle speed above 35 km / h.

It is necessary to follow the rules for towing a car.

Gearbox characteristics

The YaMZ-238VM gearbox (Fig. 2) is mechanical, eight-speed, with synchronizers in all gears except reverse, consists of a main four-speed gearbox and a dual-range planetary demultiplier.

The range switching mechanism of the demultiplier is equipped with an automatic low range locking system (ASBP).

The ASBP relay is designed in such a way that it allows the inclusion of the lower range at a speed of rotation of the output shaft of the gearbox no more than 920 min -1, which, depending on the gear ratios of the drive axle, transfer case, wheel rolling radius corresponds to a vehicle speed of 25-30 km/h.

For each particular vehicle, this value can be determined with sufficient accuracy as the quotient of dividing the maximum (kinematic) speed by 3.5.

Refill capacity of the gearbox lubrication system 7.5 liters.

The oil level is determined by the lower edge of the control hole on the right side of the spacer, located between the crankcases of the main box and the demultiplier.

The oil filler plug is located on the top cover of the main box on the left side.

A control hole can also be used as a filler.

Gearbox model - Basic design features of the gearbox

- YaMZ-238VM4 - For a double-disk clutch, without a gear lever, with a plug on the top cover, a standard cardan shaft flange with 16 holes, an output shaft cover with a flange for the speedometer drive.

- YaMZ-238VM5 - KP 238VM4 for diaphragm clutch, differs in the size of the clutch release clutch, the presence of a bracket for engaging the clutch coil spring.

- YaMZ-238VM7 - Differs from KP 238VM5 in the cardan shaft flange with ISO face splines.

- YaMZ-238VK4 - Differs from KP 238VM4 in the presence of a short gear lever installed instead of the plug on the top cover.

- YaMZ-238VK5 - KP 238VK4 for diaphragm clutch, differs in the size of the clutch release clutch, the presence of a bracket for engaging the clutch coil spring.

- YaMZ-238VK7 - Differs from KP 238VK5 in the cardan shaft flange with ISO face splines.

- YaMZ-238VL - It differs from KP 238VK4 by a solenoid valve operating at a voltage of 12V, for KP 238VK4 (VM4, VK5, VM5, etc.) - 24V, (corresponding marking on the valve itself: 12V or 24V).</li >

- YaMZ-238VL1 - KP 238VL for a diaphragm clutch, differs in the size of the clutch release clutch, the presence of a bracket for engaging the coupling coil spring, the propeller shaft flange is conventional with 8 holes Ø10 mm.

- YaMZ-238VU - Differs from KP 238VK4 only in the absence of a flange on the output shaft cover for fastening speedometer drive parts.

- YaMZ-238VU1 - KP 238VU for diaphragm clutch, differs in the size of the clutch release clutch, the presence of a bracket for engaging the clutch coil spring.

- YaMZ-238VU2 - Differs from KP 238VU in the absence of a short gear lever and the presence of a plug on the top cover.

- YaMZ-238VU3 - KP 238VU2 for diaphragm clutch, differs in the size of the clutch release clutch, the presence of a bracket for engaging the clutch coil spring.

- YaMZ-238VU4 - Gearbox 238VU2 in sealed version.

- YaMZ-238VU5 - Gearbox 238VU3 with sealed clutch housing.

- YaMZ-238VU6 - Differs from KP 238VU5 in the cardan shaft flange with ISO face splines.

- YaMZ-238VU7 - Differs from KP 238VU3 in the cardan shaft flange with ISO face splines.

- YaMZ-238VU9 - Differs from KP 238VU1 in the cardan shaft flange with ISO face splines.

Main gearbox models

Gearbox model - manufacturer - enterprise consumer:

- YaMZ-238VM - OAO ″TMZ″ - RUE "MAZ";

- YaMZ-238VK - OAO ″TMZ″ - HC "AvtoKrAZ";

- YaMZ-238VU - ″TMZ″ OJSC - AZUral OJSC;

- YaMZ-238VL - OAO ″TMZ″ - AMO "ZIL"

Gear ratios

Transmission - transmission in the main box - range in the demultiplier - gear ratio:

- - 1 - lowest - 7.30;

- - 2 - lowest - 4.86;

- - 3 - lowest - 3.50;

- - 4 - lowest - 2.48;

- - 1 - highest - 2.09;

- - 2 - highest - 1.39;

- - 3 - highest - 1.00;

- - 4 - highest - 0.71;

Reverse - reverse - low - 10.46

Gearbox operation

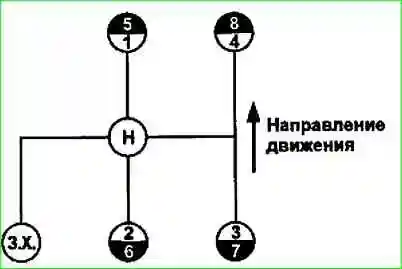

Shift gears from first to fourth and from fifth to eighth by moving the shift lever to the appropriate position (Fig. 3).

When operating the gearbox using a mechanical remote drive, the positions of the gear lever handle may differ from those shown in the diagram and are indicated in the vehicle's operating manual.

To shift from fourth to fifth gear, move the range shift button to the high range engagement positions with fourth gear engaged in the main gearbox (the location of the range control controls is indicated in the vehicle manual).

Then move the shift lever to neutral.

Hold until the indicator lamp goes out and shift into fifth gear.

To switch from fifth to fourth gear, move the range switch button to the lower range when fifth gear is engaged, while the vehicle speed should not exceed 35 km / h.

Then, shift the gear lever to the neutral position, hold until the indicator lamp goes out, and engage the fourth gear in the main box.

At the moment the gear lever passes through the neutral position, the ranges are automatically switched in the demultiplier.

The dimming of the signal light indicates the end of the range switching process.

Gearbox maintenance

The types and frequency of maintenance of the gearbox correspond to the types and frequency of maintenance of the engine.

Maintenance after running in the car

After running the car, change the oil in the gearbox housing, clean the oil intake grid and the magnet from the run-in products.

First maintenance (TO-1)

- 1. Check the oil level in the crankcase and top up if necessary.

- 2. Check the operation of ASBP nodes. The lower range in the gearbox should not be included at speed vehicle corresponding to an output shaft speed of more than 1000 min -1 .

Second maintenance (TO-2)

- 1. Perform all operations of the first maintenance TO-1.

- 2. Check and, if necessary, adjust the rear gearbox support in accordance with the vehicle manual (if the support is provided for by the vehicle design).

- 3. Clean and lubricate the parts of the gearbox air distributor using grease No. 158 according to TU 38.101.320-77.

The use of Litol 24 is allowed.

- 4. Clean and lubricate the piston seals and the walls of the range shifting cylinder.

Change the oil in the gearbox with flushing the crankcase, mesh and magnet, depending on the operating conditions, according to the following scheme:

- cars with an annual mileage of 80 thousand km or more - after 50 thousand km;

- cars with an annual mileage of less than 80 thousand km and under severe operating conditions (dirt roads, mountainous terrain or a hot, dry climatic region, etc.) - after 30-40 thousand km.

Drain the gearbox oil immediately after hot work. Flush the gearbox with industrial oil I-12A or I-20A in accordance with GOST 20799-88, for which:

- 5.5-6 l pour it into the crankcase of the box;

- set the gear lever to neutral, start the engine for 7-8 minutes, then stop it, drain the flushing oil and refill with fresh oil.

It is strictly forbidden to flush the gearbox with kerosene or diesel fuel to avoid failure of the oil pump due to insufficient suction vacuum and, as a result, failure of the gearbox.

In case of a complete overhaul of the gearbox, lubricate the oil pump with the oil used in the gearbox before installation.