Usually, the timing belt is designed to operate for 30,000 km

It is necessary to inspect the belt at each maintenance and check its tension

When the tension is loosened, the belt teeth wear out quickly, in addition, the belt may jump on the toothed pulleys of the crankshaft and camshaft, which leads to a violation of the valve timing, loss of power, and engine damage.

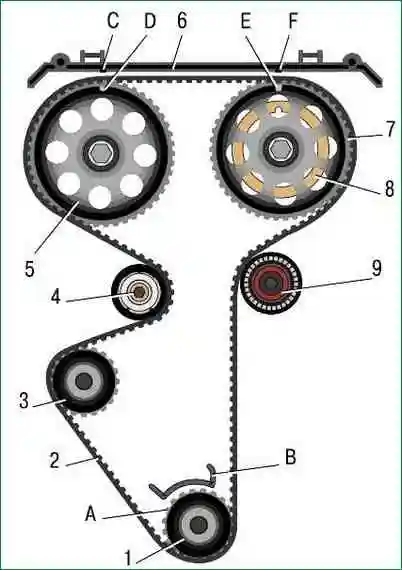

Scheme of the timing mechanism drive: 1 - crankshaft toothed pulley; 2 - toothed belt; 3 - water pump pulley; 4 - tension roller; 5 - exhaust camshaft pulley; 6 - rear protective cover of the toothed belt; 7 - intake camshaft pulley; 8 - ring (synchronization disk) for the phase sensor; 9 - support roller; A - TDC setting mark on the crankshaft toothed pulley; B - installation marks on the cover of the oil pump; C, F - alignment marks on the rear protective cover of the toothed belt; D - alignment mark of the exhaust camshaft; E - inlet camshaft alignment mark

Camshafts are driven by pulley 1 (fig. 1) of the crankshaft by means of a belt drive with a toothed belt.

There are two rollers under the camshaft pulleys: tension roller 4 on the left, support roller 9 on the right.

At the support roller, the mounting hole is made in the center of the inner race, at the tension roller it is located eccentrically (off-center by 6 mm).

Therefore, by turning the tension roller relative to the mounting bolt, you can adjust the belt tension.

The camshaft pulleys are distinguished by the fact that a timing disk 8 is welded to the pulley 7 of the intake camshaft, which ensures the operation of the phase sensor.

The front and back of the drive is closed with plastic covers.

To set the valve timing, there are installation marks A, D, E on the pulleys, B on the oil pump cover, as well as C and F on the back cover of the drive belt.

With correctly installed phases, mark A should coincide with mark B, and marks D and E should match marks C and F.

Replace the camshaft drive belt if, upon inspection, you find:

- - traces of oil on any surface of the belt;

- - signs of wear of the serrated surface, cracks, undercuts, folds and delamination of the fabric from the rubber;

- - cracks, folds, depressions or bulges on the outer surface of the belt;

- - fraying or delamination on the end surfaces of the belt.

You will need: the tools needed to remove the alternator drive belt and the timing belt front cover, a 15 wrench, a 17 ring wrench, a special wrench to turn the tension roller or a snap ring remover, a mounting spatula or a large screwdriver.

Disconnect the wire from the negative terminal of the battery

Remove the alternator drive belt.

Set the piston of the 1st cylinder to the TDC position (see "Setting the piston of the first cylinder to the TDC position of the compression stroke").

Loosen the tensioner bolt with a 15 wrench and turn the tensioner to loosen the belt tension.

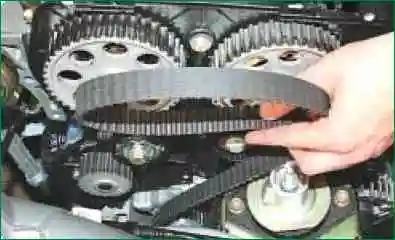

Remove the belt from the camshaft pulleys, idler pulley and water pump toothed pulley.

In order to unscrew the bolt securing the alternator drive pulley, it is necessary to fix the crankshaft from turning.

To do this, after removing the plug in the clutch housing, the assistant must use a mounting spatula or a large screwdriver to hold the crankshaft by the teeth of the flywheel crown.

Unscrew the crankshaft pulley bolt with a 17 spanner.

Remove the bolt with washer and remove the alternator drive pulley from the crankshaft.

Remove the washer from the timing belt pulley.

Remove the timing belt from the crankshaft sprocket.

Before installing a new belt, clean the pulleys and tensioner from dirt and grease, degrease them with white spirit.

Install the camshaft drive belt in the reverse order of removal.

The alternator drive pulley can only be installed in one position.

The groove of the pulley must fall on the lug of the timing drive pulley.

When installing the belt, ensure the tension of its leading branch.

After installing the belt, adjust its tension.

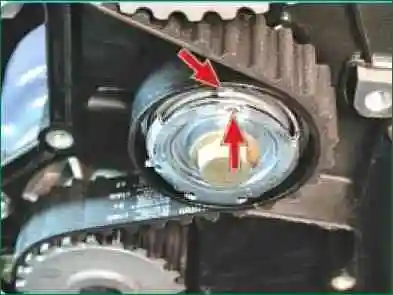

To do this, use a special key or a snap ring remover inserted into the grooves of the outer disk of the tension roller, turn the roller counterclockwise

The roller must be turned until the notch on the outer disk aligns with the rectangular protrusion on the inner sleeve of the idler.

Tighten the tension roller bolt with a 15 wrench.

If you hear noise from the camshaft drive belt, it is likely that the idler roller bearing has failed.

Remove the roller, check the performance of its bearing.

If seizing, axial play, or traces of lubricant leakage from the bearing are noticeable when turning the bearing, replace the tensioner.

To replace the roller, before installing the belt, completely unscrew the bolt of its fastening and remove the roller.

Install the new idler pulley in the reverse order of removal.

When doing this, the roller disc with the marking must point outward.

Adjust the timing belt tension.

Install all removed parts and assemblies in the reverse order of removal.