Maintenance of the ZIL-5301 clutch

Adjustment of the clutch drive

Maintenance of the clutch consists of checking and adjusting the full travel of the clutch pedal, the free travel of the piston pusher of the master cylinder,

free travel of the clutch release bearing sleeve and bleeding air from the hydraulic system of the clutch control mechanism.

The full travel of the clutch pedal (to the stop in the lower fixed limiter) should be equal to 180-185 mm.

The travel is measured in the middle of the pedal platform along the chord of the arc of a circle described by it.

The movable stop located in the upper part of the pedal allows you to adjust the full travel of the pedal by changing its upper position.

After adjustment, the position of the upper stop should be fixed with a lock nut.

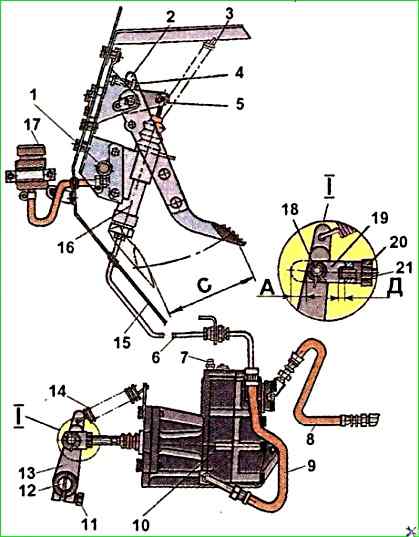

Clutch drive: 1 - lower pedal stop; 2 - pedal; 3 - release spring; 4 - movable stop (adjusting bolt); 5 - eccentric pin; 6 - hydraulic drive tube; 7 - bypass valve; 8 - air supply hose to the booster; 9 - hydraulic drive hose; 10 - pneumohydraulic booster; 11 - tension bolt; 12 - clutch release fork; 13 - clutch release fork lever; 14 - spring; 15 - cab front shield; 16 - master cylinder; 17 - master cylinder reservoir; 18 - finger; 19 - pusher fork; 20 - lock nut; 21 - pusher; A - free travel of the pusher, corresponding to the free travel of the clutch release sleeve; C - full travel of the clutch pedal; D - the amount of the end face of the pusher protruding from the threaded hole in the fork

The free travel of the master cylinder piston pusher (1-2 mm) is checked by moving the clutch pedal.

The travel of the middle of the pedal pad should be within 5-10 mm before the pusher touches the master cylinder piston.

Adjustment is performed with the pedal in the extreme upper position by turning the eccentric pin 5, which connects the upper eye of the pusher with the clutch pedal lever.

After adjustment, it is necessary to tighten and cotter the pin nut.

The pedal is held in the extreme upper position by a release spring.

The free travel of the clutch release bearing sleeve (should be 3-4 mm) is checked by moving the clutch release fork lever with the release spring 14 removed (see Fig. 1).

The lever travel "A" (free play), measured along the axis of the connecting pin 18, should be equal to 6-8 mm.

The lever travel is adjusted by rotating the pusher 21, the position of which is then fixed with the lock nut 20.

After adjustment, it is necessary to check the size "D" - the amount of protrusion of the end of the pusher from the threaded hole of the fork, which should be 0-7 mm.

If the size "D" goes beyond the specified limits (it is permissible for the end of the pusher to sink to a depth of no more than 5 mm), then the lever on the clutch release fork should be rearranged, spreading the marks on the end of the fork and the lever.

After this, it is necessary to re-adjust the lever travel.

The marks on the lever and fork are intended for their initial installation.

It is necessary to emphasize that, in addition to slippage, the lack of free play leads to severe wear of the friction linings of the driven disk.