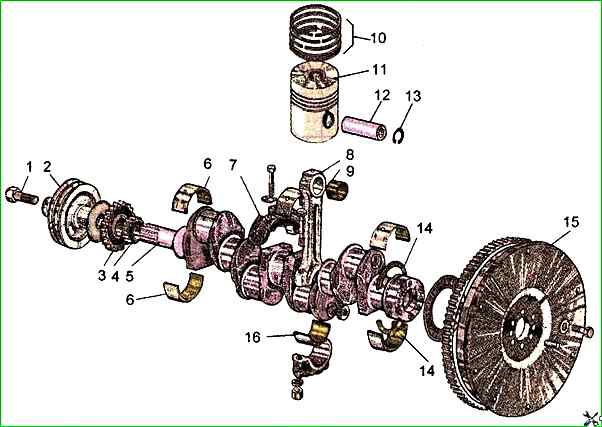

Laying the D-245 crankshaft

Before assembly, each crankshaft must be checked on a magnetic or ultrasonic flaw detector for the absence of micro and macro cracks; and also for compliance of the selected set of main bearing shells with the size of the main journals

Mechanical damage (scores, dents, nicks, etc.) on the crankshaft journals and main bearing shells are not allowed.

The main journals, bearing shells and bearing seats should be wiped with a napkin and blown with compressed air.

The main bearing caps should fit tightly into the block seats.

Rearranging and turning over the main bearing caps is not allowed.

Disassembling the main bearing shells is not allowed.

The shells should be installed in the corresponding cylinder block seats.

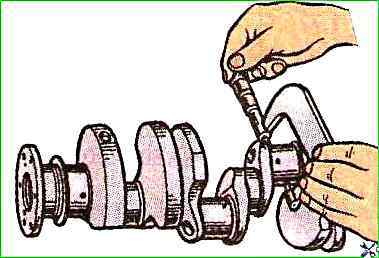

Before installing the crankshaft, the main journals and liners must be lubricated with engine oil.

The thrust half rings installed on the walls of the bed of the fifth main support and the bearing cap must be selected so that the longitudinal play of the crankshaft after tightening the main bearing bolts is 0.14-0.37 mm.

The valve mechanism crackers must protrude above the plane of the washer by 0.5-2.0 mm;

Pistons, connecting rods and piston pins of the same weight group must be selected for one diesel engine; the difference in weight of the connecting rods in a set with pistons must not exceed 30 g.

The main and connecting rod journals and bearing liners of the crankshaft are made of two nominal sizes.

Nominal dimensions of crankshaft journals:

- Diameter of shaft journal 1H - main journal - 75.25-0.083; connecting rod journal - 68.25-0.077;

- Diameter of shaft journal 2H - main journal - 75.00-0.083; connecting rod journal - 68.00-0.077

Nominal dimensions of crankshaft bearing shells:

- Inner diameter of BN1 liner - main journal - 75.25-0.033 mm; connecting rod journal - 68.25+0.025 mm;

- Inner diameter of BN2 bearing - main journal - 75.00-0.033 mm; connecting rod journal - 68.00+0.025 mm

Crankshafts with connecting rod and main journals made to the second nominal size have an additional designation on the first cheek:

- 2K - main journals of the second nominal size;

- 2Ш - connecting rod journals of the second nominal size;

- 2КШ - connecting rod and main journals of the second nominal size.

Repair dimensions of crankshaft journals

Diameter of shaft journal D1 - main journal - 74.75-0.083 mm; Connecting rod journal - 67.75-0.077 mm;

Diameter of shaft journal P1 - main journal - 74.50-0.083 mm; connecting rod journal - 67.50-0.077 mm;

Diameter of shaft journal D2 - main journal - 74.25-0.083 mm; connecting rod journal - 67.25-0.077 mm;

Diameter of shaft journal P2 - main journal - 74.00-0.083 mm; connecting rod journal - 67.00-0.077 mm;

Diameter of shaft journal D3 - main journal - 73.75-0.083 mm; connecting rod journal - 66.75-0.077 mm;

The diameter of the journal of the shaft P3 - the main journal - 73.50-0.083 mm; connecting rod journal - 66.50-0.077 mm;

The diameter of the journal of the shaft D4 - the main journal - 73.25-0.083 mm; connecting rod journal - 66.25-0.077 mm;

The diameter of the journal of the shaft P4 - the main journal - 73.00-0.083 mm; connecting rod journal - 66.00-0.077 mm;

When checking the tightening of the main bearing cap bolts for additional turning, the torque value should not exceed 240 Nm.

The tightening torque of the main bearing bolts should be 200-220 Nm.

In this case, the crankshaft should turn smoothly, without jamming, with a torque of no more than 3 Nm.