The main reason for replacing the chain is excessive stretching.

When the camshaft drive chain is stretched too much, the chain starts to "rattle" when the engine is running.

This is noise in the front part of the engine, increasing at medium speeds and variable loads (the noise is clearly audible when releasing the gas from 2500 to 1000 min -1).

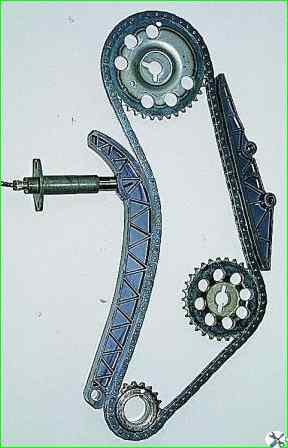

Of course, in this case, you need to change not only the chain, but also the sprockets, shoe and chain guide.

Remove the cylinder head cover (see the article - "Replacing the cylinder head cover gasket").

Turn the crankshaft until the mark on the camshaft sprocket coincides with the mark on the camshaft bearing housing. (the chain is removed for clarity in the photo)

Removing the crankshaft pulley

Disconnect the camshaft sprocket with the chain from the camshaft (see the article - Removing the camshaft and valve drive levers)

Remove the chain from the sprocket. For clarity, we show the chain removal operation on a dismantled engine.

Unscrew the three bolts securing the oil pan to the camshaft drive cover.

Using a 10 mm socket, unscrew the three nuts and six bolts securing the camshaft drive cover to the cylinder block.

The "ground" is secured under one nut (on the left side) wire.

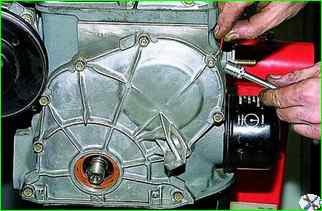

Removing the camshaft drive cover

Removing the sealing gasket

Using a 17 mm head, unscrew the axle of the hydraulic chain tensioner shoe and remove the axle.

Remove the shoe tensioner.

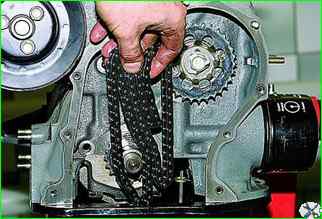

Remove the chain from the crankshaft sprockets and the oil pump drive shaft.

Remove the camshaft drive chain.

Use a puller to press the sprocket off the nose of the crankshaft and remove it

The sprocket is fixed on crankshaft with a segment key.

To remove the key, carefully, trying not to damage the key and the shaft, knock it out of the crankshaft groove with a chisel and remove the key.

Use a chisel to loosen the bolt securing the sprocket of the oil pump drive shaft.

Use a 17 mm open-end wrench to loosen the sprocket mounting bolt.

Hold the sprocket from turning with a screwdriver resting through the hole in the sprocket on the head of the bolt securing the thrust flange of the roller.

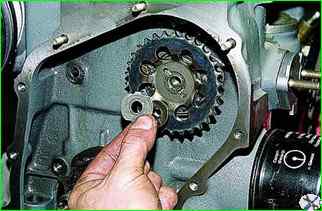

Remove the washers.

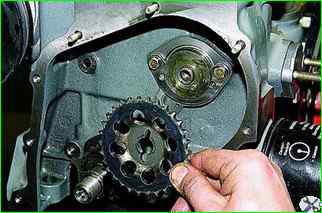

Remove the sprocket oil pump drive shaft

Install the drive mechanism parts in the reverse order.

Having installed the key in the groove of the crankshaft, we put on the sprocket and press it onto the crankshaft, tightening the pulley mounting nut with a wrench.

Having unscrewed the nut, we press the sprocket with a tool head of a suitable size (a piece of pipe).

Before installing the chain, align the mark (risk above the keyway) on the crankshaft sprocket with the mark (protrusion) on the cylinder block

And we combine the mark on the camshaft sprocket with the mark on the shaft bearing housing

Having installed the chain and hydraulic tensioner, we turn the crankshaft clockwise two turns and check the coincidence installation marks.

Remove parts are installed in the reverse order.