We replace the seals when oil leaks from under the seals. Also when repairing the gearbox

Replacing the gearbox input shaft seal

We perform the work on an inspection pit or lift.

Remove the gearbox (see Removing the gearbox).

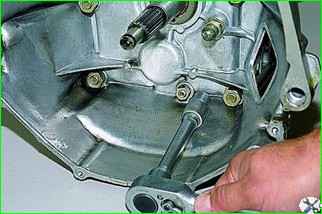

Using a 13 mm socket, unscrew one nut at the bottom of the gearbox

Using a 17 mm socket, unscrew six more nuts.

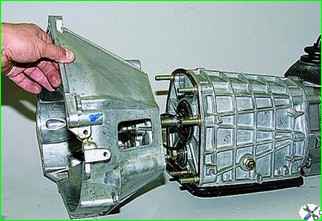

Separate the clutch housing from the gearbox.

Pry off the seal with a mounting blade or screwdriver

We remove it from the clutch housing socket.

After lubricating the working surface of the seal with a thin layer of Litol-24 grease, we press it in with a suitable piece of pipe (with an outer diameter of 44 mm and an inner diameter of at least 35 mm)

We assemble in the reverse order.

We replace the sealing gasket between the housings with a new one and lubricate it with a thin layer of silicone sealant.

Replacing the secondary shaft seal of the gearbox

We carry out the work on an inspection pit or lift.

We remove the transfer case with the intermediate shaft (see. Transfer case removal).

Removing the rubber centering ring.

In order to stop the flange from turning, insert the elastic coupling mounting bolt into its hole

Using a 30 mm socket, loosen the flange mounting nut

Remove it (the nut is installed with thread sealant)

Remove the washer (it is installed with the bulge facing the nut).

Using a long punch made of soft metal, we strike the flange, turning it

The flange can also be removed with a three-jaw puller (the photo was taken on a dismantled box)

Remove the flange.

Pry the secondary shaft oil seal with a screwdriver and remove it

After lubricating the working surface of the oil seal with a thin layer of Litol-24 grease, press it in with a suitable piece of pipe.

Reinstall the dismantled parts in the reverse order.

Oil seal numbers according to the catalog:

- 2101-170104340000260 - Primary shaft of the gearbox;

- 2101-170121040000240 - Secondary shaft of the gearbox