We carry out the work on an inspection pit or lift.

Disconnect the negative wire from the battery

Remove the transfer case with the intermediate shaft (you can see how to remove it in the article - Removing and installing the transfer case).

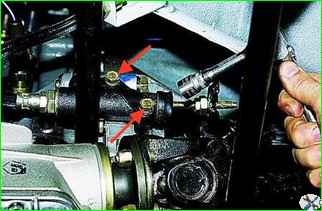

Disconnect the wires from the reverse light switch.

After unscrewing the bolts securing the clutch slave cylinder to the clutch housing, move the cylinder forward without disconnecting the hydraulic drive.

In the passenger compartment, use a Phillips screwdriver to unscrew the two screws securing the plastic cover of the gear shift lever.

After removing the handle from the lever rod, remove the cover with the rubber boot.

The operations for removing the lever rod are shown on the dismantled gearbox for clarity.

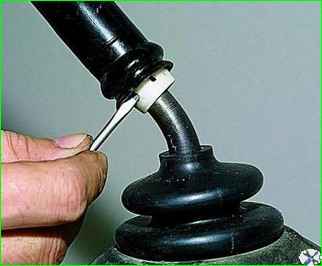

Press the lever rod down and use a screwdriver to pry up the petals of the locking sleeve

Remove the petals of the locking sleeve from the annular groove of the rod

Remove the gearshift lever rod.

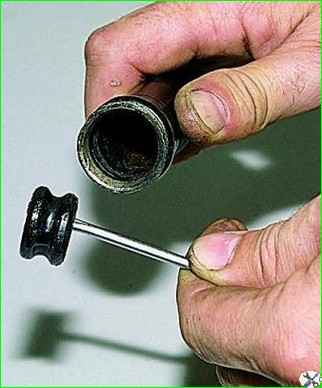

Use a screwdriver to unclamp the petals of the spacer sleeve

Removing the spacer sleeve from the lever

Remove the rubber elastic bushing from the lever

Remove the locking bushing from the lever.

Prying with a screwdriver, we extract another elastic bushing from the hole in the lever rod

We extract the thrust pad from the rod.

We unscrew the bolts securing the starter to the clutch housing.

On a VAZ-21214 car, having unscrewed the upper bolt securing the starter, release the lower end of the rear support bracket of the engine intake pipe

Using a 13 mm head, unscrew the bolt securing the upper end of the support bracket to the intake pipe

Removing the bracket.

Remove the front propeller shaft (see Removing the propeller shaft).

Using a 10 mm wrench, unscrew the four bolts securing the clutch housing cover.

Using a 13 mm head, unscrew the bolt securing the clamp of the inlet pipe to the bracket.

Take out the bolt.

Using a 13 mm open-end wrench, unscrew the two nuts securing the bracket to the gearbox.

Remove the "embedded" bolt.

Remove the bracket.

Using a 19 mm head with a universal joint and an extension, unscrew the four bolts securing the gearbox to the cylinder block.

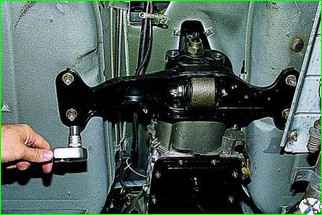

Using a 13 mm head, unscrew the two nuts securing the gearbox support bracket (the third support of the power unit).

Using a 13 mm socket, unscrew the four nuts securing the crossmember of the rear suspension of the power unit to the body.

Remove the cross member with the support

Having moved the gearbox back, we remove it.

When removing or installing the gearbox, do not rest the input shaft of the gearbox on the clutch assemblies, so as not to damage them.

We install the gearbox in the reverse order

Before installation, apply a thin layer of SHRUS-4 grease to the splined end primary shaft.

After installing the box, adjust the free travel of the clutch release fork pusher.

Before installing the rod on the gear shift lever, insert the cushion and bushings into rod hole.

Gearbox mount tightening torques

Clutch housing to gearbox nut М10x1.25 31.8-51.4 Nm (3.25-5.25 kgf m)

Clutch housing to gearbox nut М8 15.7-25.5 Nm (1.6-2.6 kgf m)